A special high-voltage source resistance tester for the resistance of spark plug porcelain components

A technology of resistance tester and high voltage source, which is applied in the field of spark plugs, can solve the problems of slowing down the resistance detection speed of ceramic components, unable to measure data, and affecting the measured value, so as to save manual retesting and verification work and improve measurement Efficiency, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

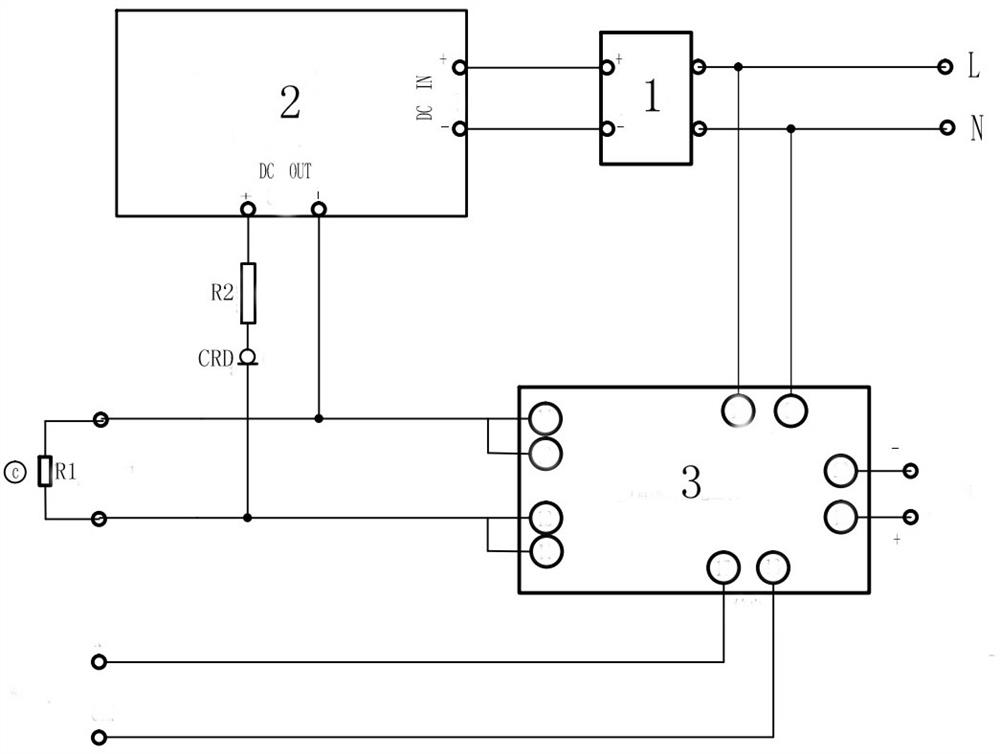

Image

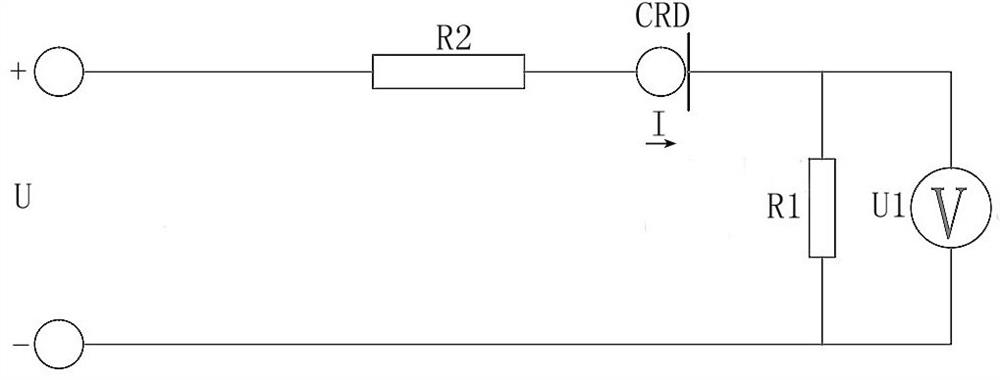

Examples

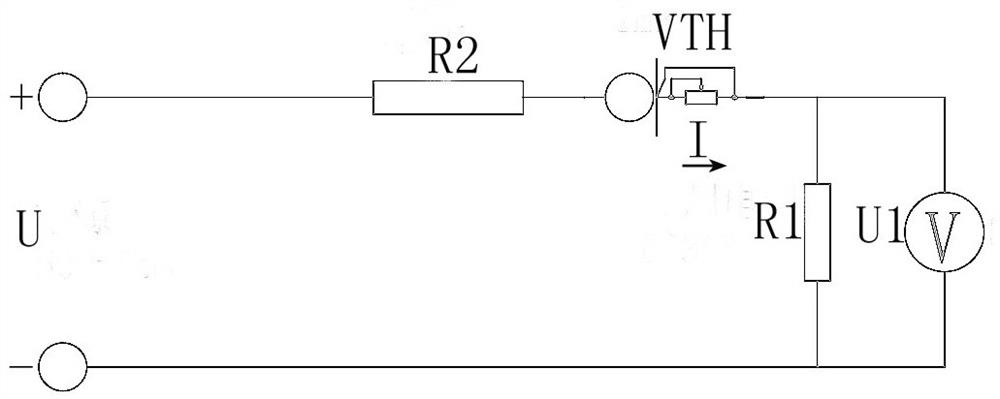

Embodiment 2

[0030] The difference between this embodiment and Embodiment 1 is that in this embodiment, a constant current triode is used instead of a constant current diode, and the circuit schematic diagram using a constant current triode is as follows image 3 shown. The constant current triode can continuously adjust the constant current within a certain range. Compared with the constant current diode in Example 1, the constant current triode is more convenient in specific use, for example, it can be adapted to input sources of different voltages And DC smart voltmeters with different ranges.

[0031] In the present invention, by setting an internal voltage boosting circuit, the output voltage of the tester can reach enough to break down the oxide layer at the screw end of the spark plug and the center electrode, thereby reducing and eliminating the problem of the test pen touching the insulating oxide layer when measuring the resistance of the spark plug porcelain component. The adve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com