Fault diagnosis method of compressor shafting based on three-dimensional space axle center orbit

A shaft trajectory and fault diagnosis technology, applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve problems such as equipment accidents and affect the smooth operation of the rotor, and achieve the effect of improving accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Below in conjunction with accompanying drawing, content of the present invention is described in further detail

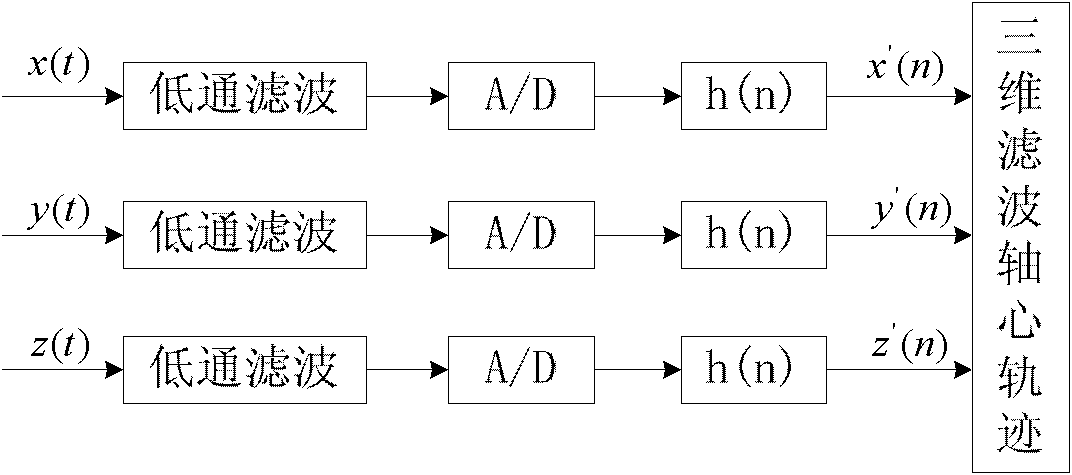

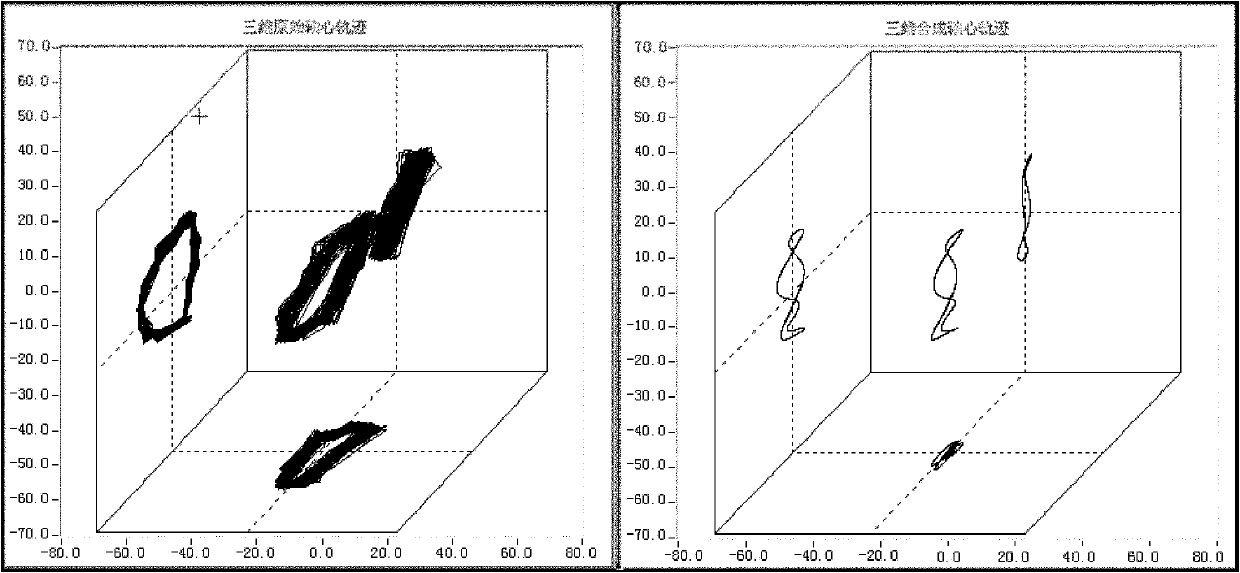

[0059] see figure 1 As shown in the figure, after measuring the journal vibration by using two eddy current sensors (X direction and Y direction) installed in the same section perpendicular to each other and an eddy current sensor installed in the axial direction (Z direction), the compressor shaft A group of vibration signals x(t), y(t), z(t) of a group of vibration signals, imitating the composition method of the axis trajectory, combining three sensor signals (X direction, Y direction and Z direction) to obtain a three-dimensional space axis track.

[0060] see figure 2 Shown, the installation method of the sensor when measuring the axial vibration signal. In actual compressor condition monitoring and fault diagnosis, not only the radial vibration displacement of the compressor shaft must be measured, but also its axial displacement is one of the very...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com