Saturable absorber based on plasmon axial vibration mode

A saturable absorption, axial vibration technology, applied in the structure/shape of the active medium, lasers, electrical components, etc., can solve the problems of single surface plasmon resonance absorption peak, difficult to control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

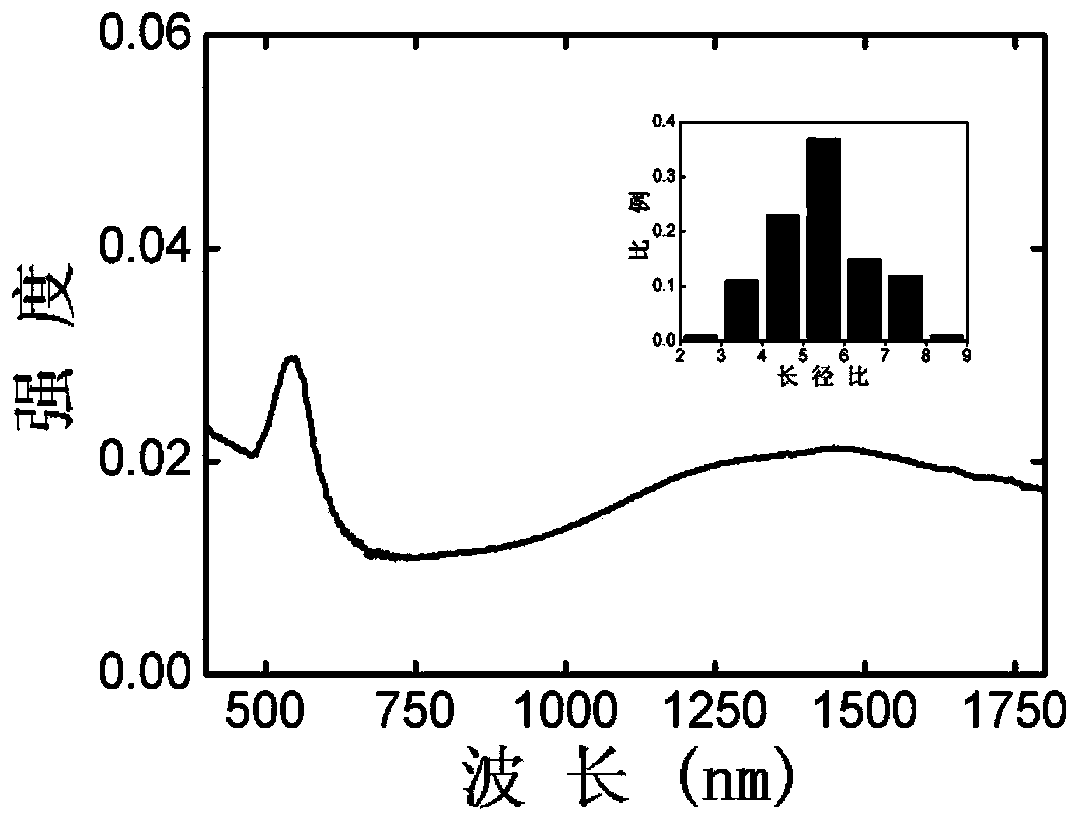

[0054] Example 1: Preparation of a saturable absorber material mixed with gold nanorods and sodium carboxymethylcellulose (NaCMC) and used for 1560nm mode-locked laser output

[0055] 1. Sample preparation process

[0056] The synthesis of gold nanorods adopts the "seed crystal method". First, 10mL of cetyltrimethylammonium bromide (0.2M), 10mL of chloroauric acid solution (0.5mM) and 1mL of fresh sodium borohydride (0.01mM) were mixed uniformly in a beaker and stirred, After stirring for two hours, a seed solution was obtained. Then, 20ml of cetyltrimethylammonium bromide (0.15M), 12.5ml of 5-bromosalicylic acid (0.2M), 2ml of silver nitrate aqueous solution (4mM) and 35.2ml of chloroauric acid solution (0.1 mM) were mixed uniformly in the flask, and then 1 mL of ascorbic acid (0.1 mM) was added to obtain a growth solution. Finally, 0.5 mL of seed solution was added to the above growth solution, and vigorously stirred for 30 minutes. After the reaction solution was left s...

Embodiment 2

[0059] Example 2: Preparation of a saturable absorber material mixed with gold nanorods and polyvinyl alcohol (PVA) and used for 1560nm mode-locked laser output

[0060] 1. Sample preparation process

[0061]The synthesis of gold nanorods adopts the "seed crystal method". First, 10mL of cetyltrimethylammonium bromide (0.2M), 10mL of chloroauric acid solution (0.5mM) and 1mL of fresh sodium borohydride (0.01mM) were mixed uniformly in a beaker and stirred, After stirring for two hours, a seed solution was obtained. Then, 20ml of cetyltrimethylammonium bromide (0.15M), 12.5ml of 5-bromosalicylic acid (0.2M), 2ml of silver nitrate aqueous solution (4mM) and 35.2ml of chloroauric acid solution (0.1 mM) in the flask and mix well, then add 1mL ascorbic acid (0.1mM), and the growth solution is prepared successfully. Finally, 0.5 mL of the seed solution was added to the growth solution, and vigorously stirred for 30 minutes. After the reaction solution was left standing for 24 hou...

Embodiment 3

[0064] Example 3: Preparation of a saturable absorber material mixed with gold nanorods and polyvinylpyrrolidone (PVP) and used for 1560nm mode-locked laser output

[0065] 1. Sample preparation process

[0066] The synthesis of gold nanorods adopts the "seed crystal method". First, mix 10 mL of cetyltrimethylammonium bromide (0.2M), 10 mL of chloroauric acid solution (0.5 mM) and 1 mL of fresh sodium borohydride (0.01 mM) in a beaker and stir, After stirring for two hours, a seed solution was obtained. Then, 20ml of cetyltrimethylammonium bromide (0.15M), 12.5ml of 5-bromosalicylic acid (0.2M), 2ml of silver nitrate aqueous solution (4mM) and 35.2ml of chloroauric acid solution (0.1 mM) in the flask were mixed evenly, and then 1 mL of ascorbic acid (0.1 mM) was added, so that the growth solution was successfully prepared. Finally, 0.5 mL of the seed solution was added to the growth solution, and vigorously stirred for 30 minutes. After the reaction solution was left stand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com