Hydraulically driven tractor

a hydraulic drive and tractor technology, applied in the direction of drilling machines and methods, percussion drilling, drilling machine/well accessories, etc., can solve the problems of coiled tubing being susceptible to helical buckling, damaging the coiled tubing itself, and most tractors that are currently available are somewhat incompatible with coiled tubing equipmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

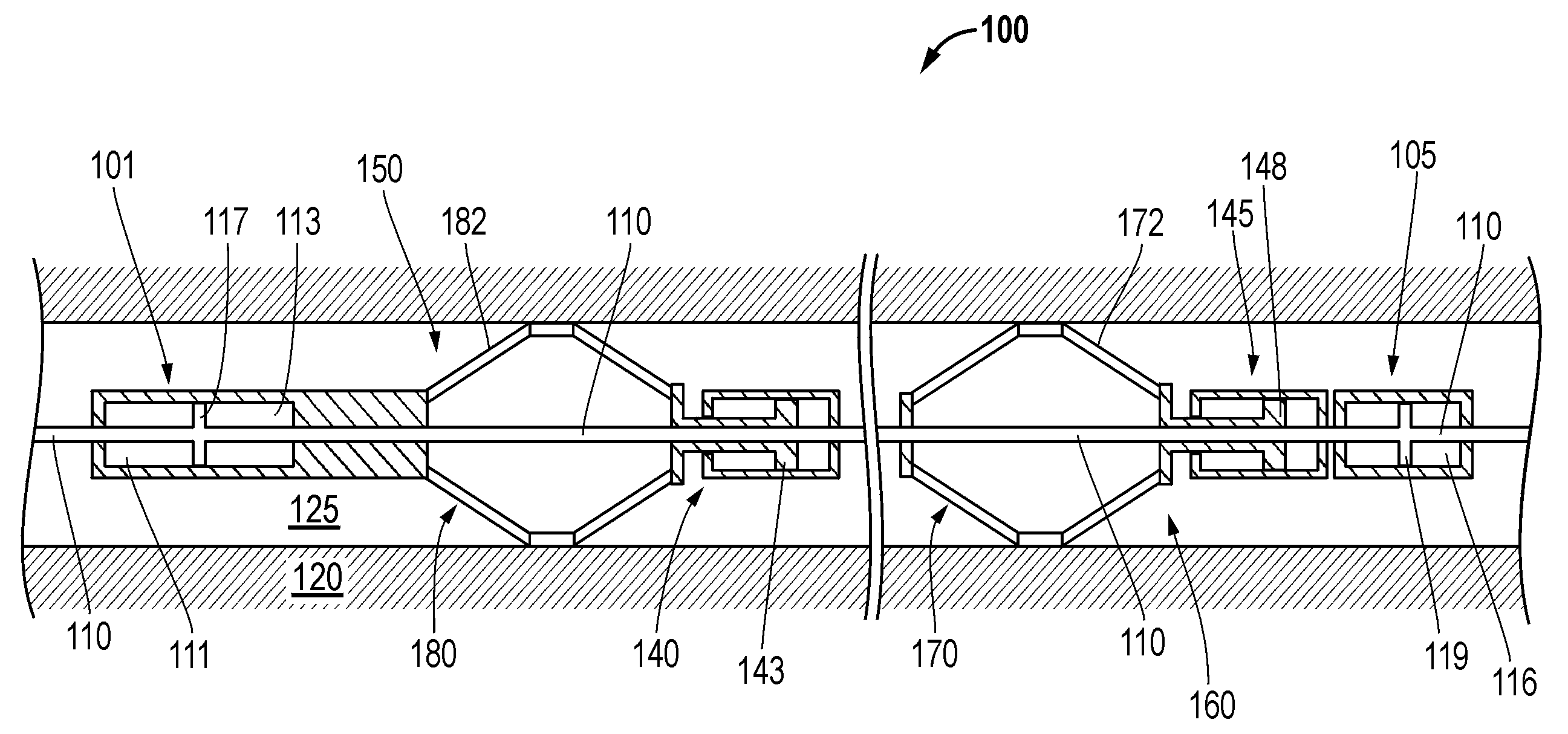

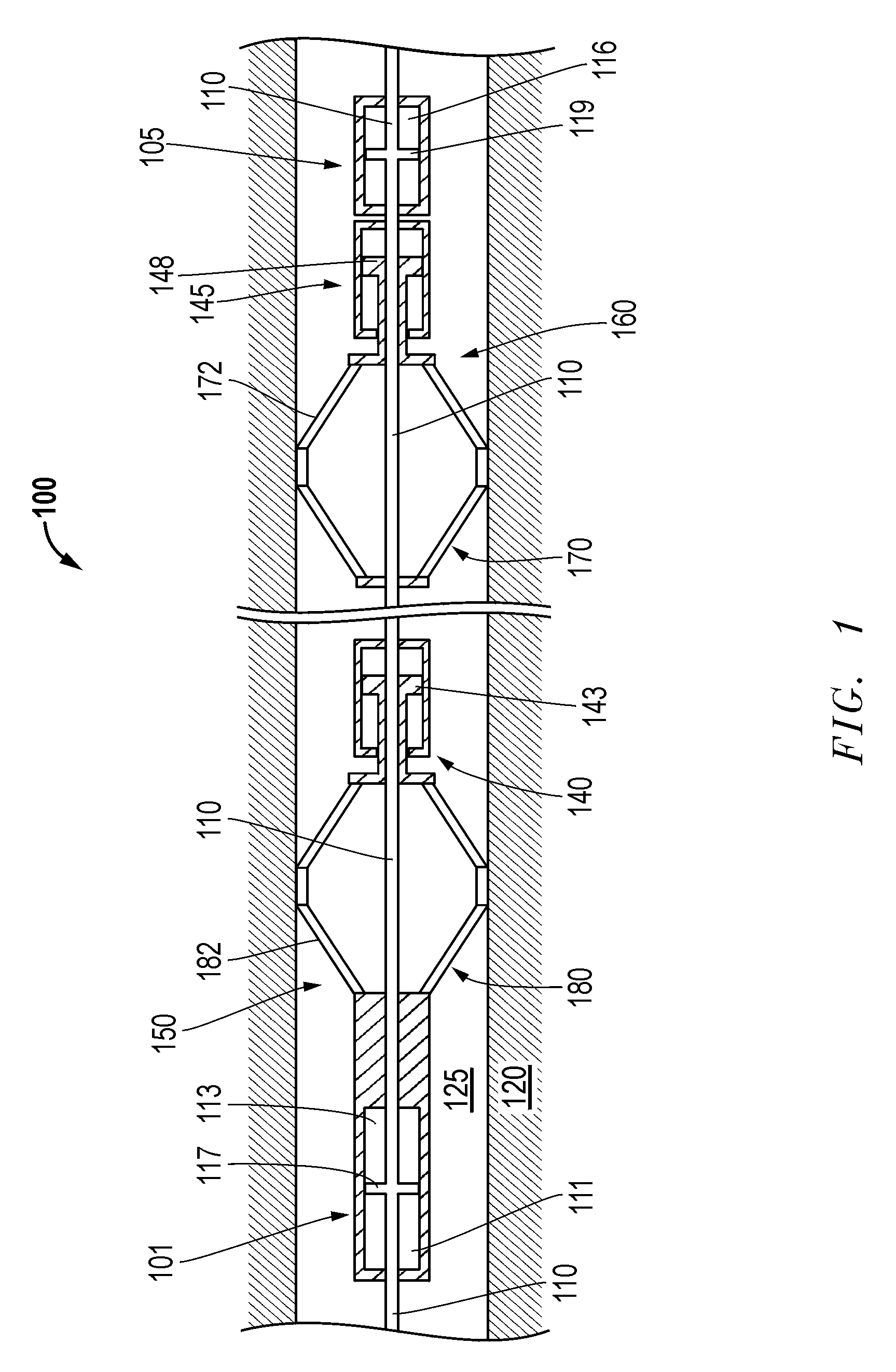

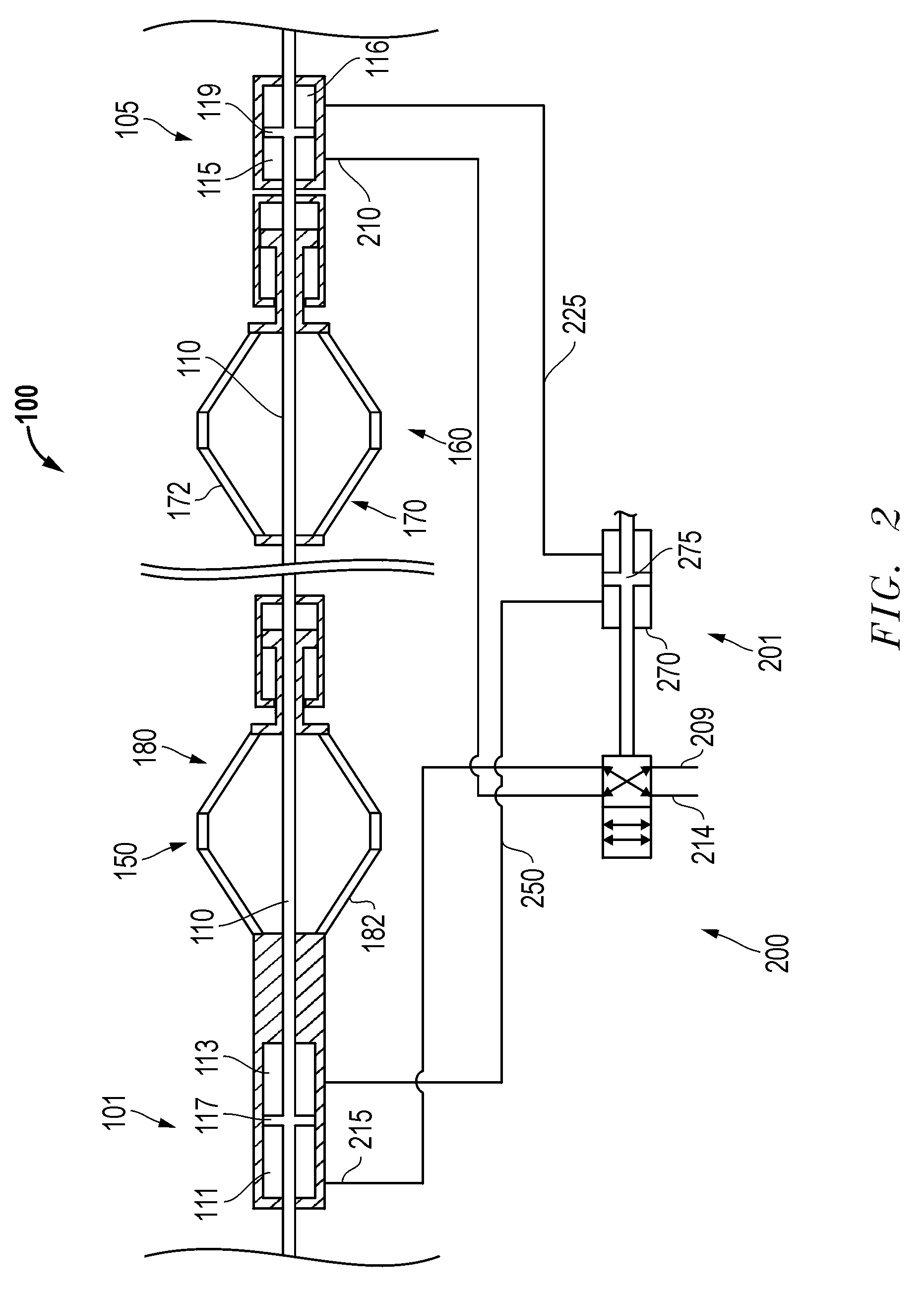

[0016]Embodiments are described with reference to certain downhole tractors for use in an oil well. In particular, dual anchor reciprocating double armed embodiments are described. However, a variety of configurations may be employed. Regardless, embodiments described may include the ability to advance downhole in a continuous manner, maintaining downward movement and substantially avoiding static friction. In fact, certain embodiments may also maintain a degree of anchoring at all times during advancement so as to avoid the occurrence of spring-back as detailed below.

[0017]Referring now to FIG. 1 an embodiment of a hydraulically driven tractor 100 is shown disposed within a production region 120 of a well 125. The tractor 100 may be directed to this location to aid in hydrocarbon recovery efforts from the production region 120. The tractor 100 has adjacent assemblies 150, 160 that each includes a housing 101, 105, an anchor 170, 180 and actuators 140, 145 therefor. A piston 110 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com