Sealing bush, hydraulic unit, and check valve

A sealing bushing and sealing device technology, applied in the direction of the valve device, the parts in contact with the valve element and the valve seat, and the lifting valve, etc., can solve the problem of expensive manufacturing of the sealing bushing, achieve simple and accurate manufacturing, and reduce assembly The effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

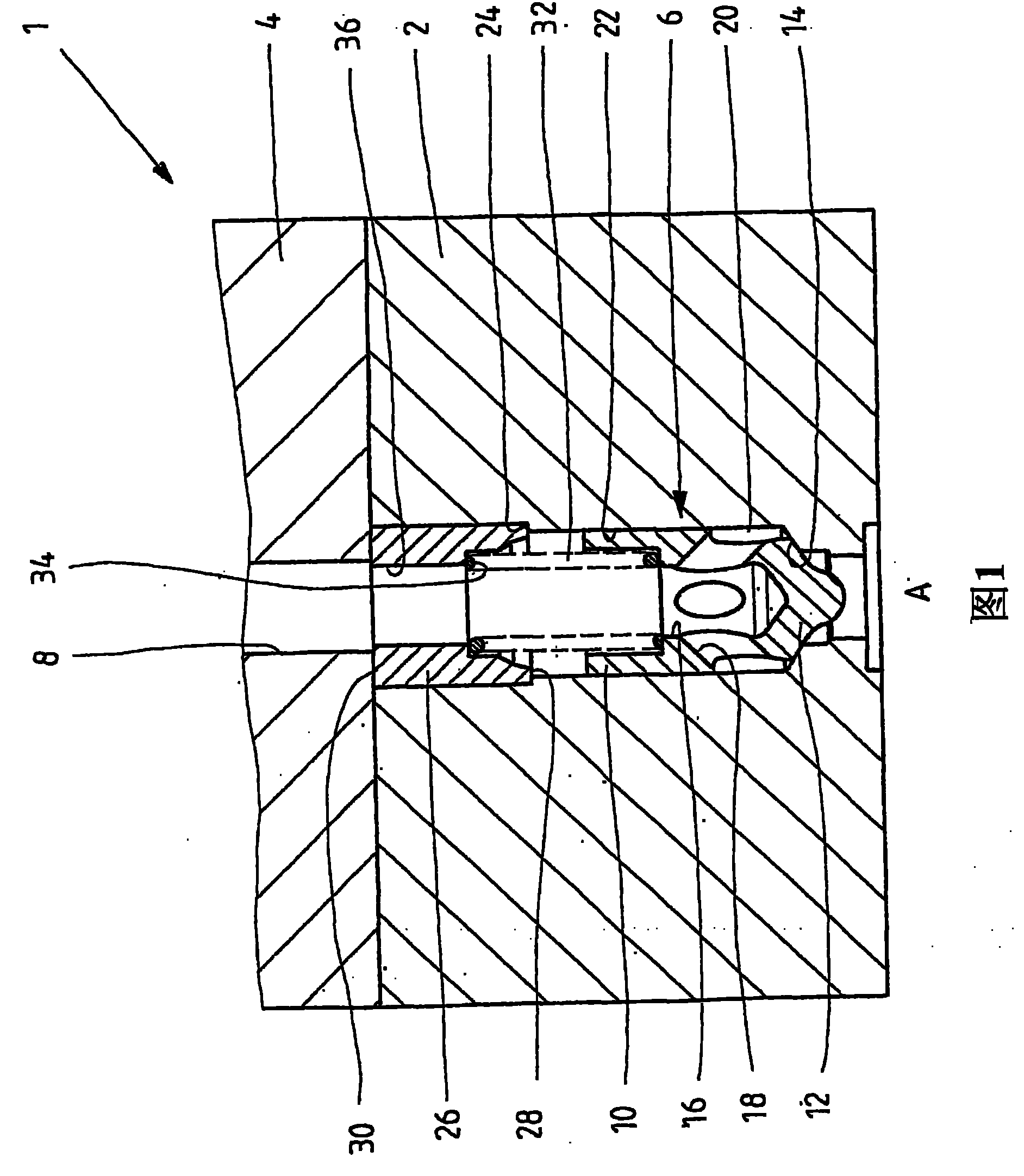

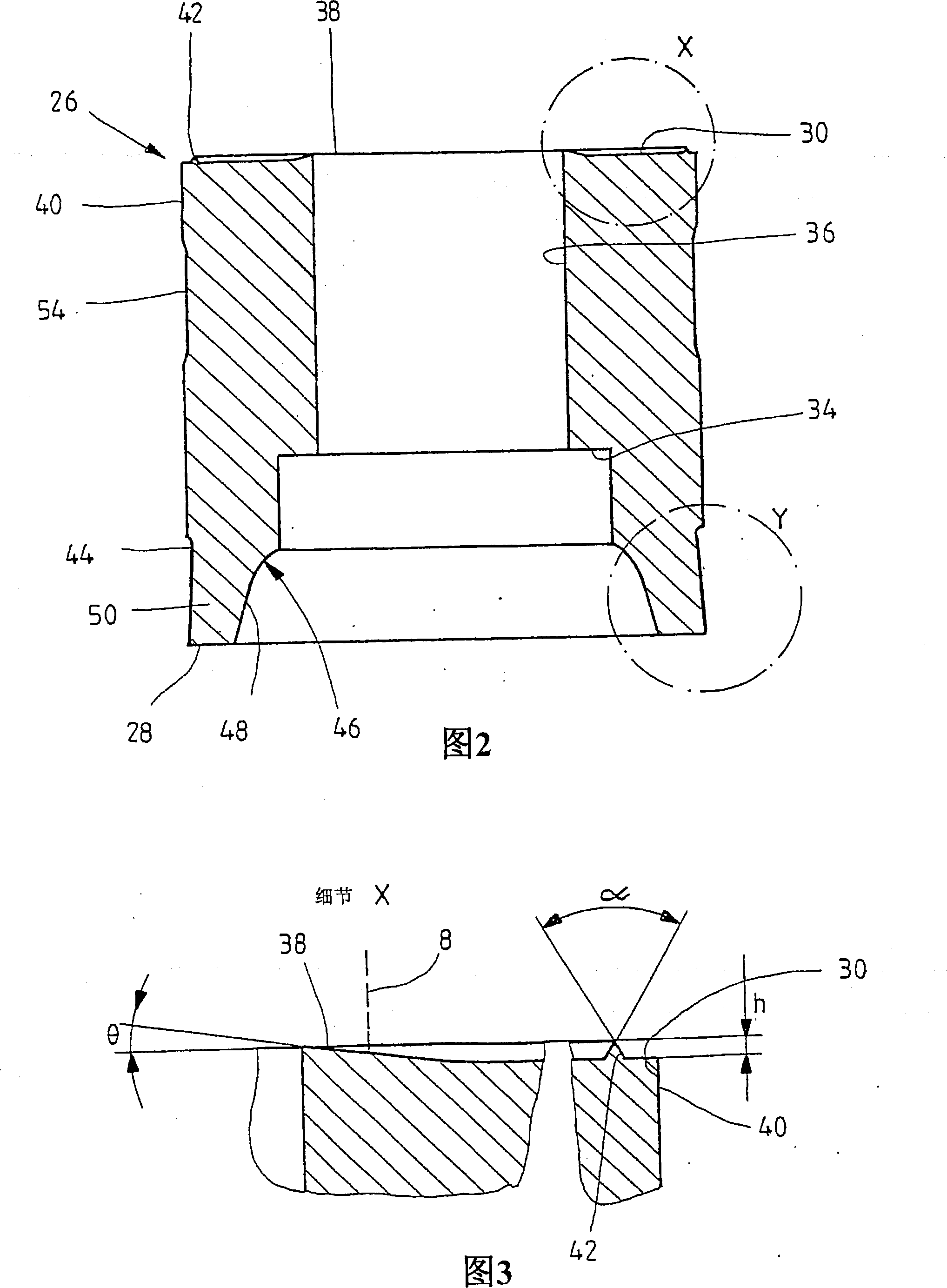

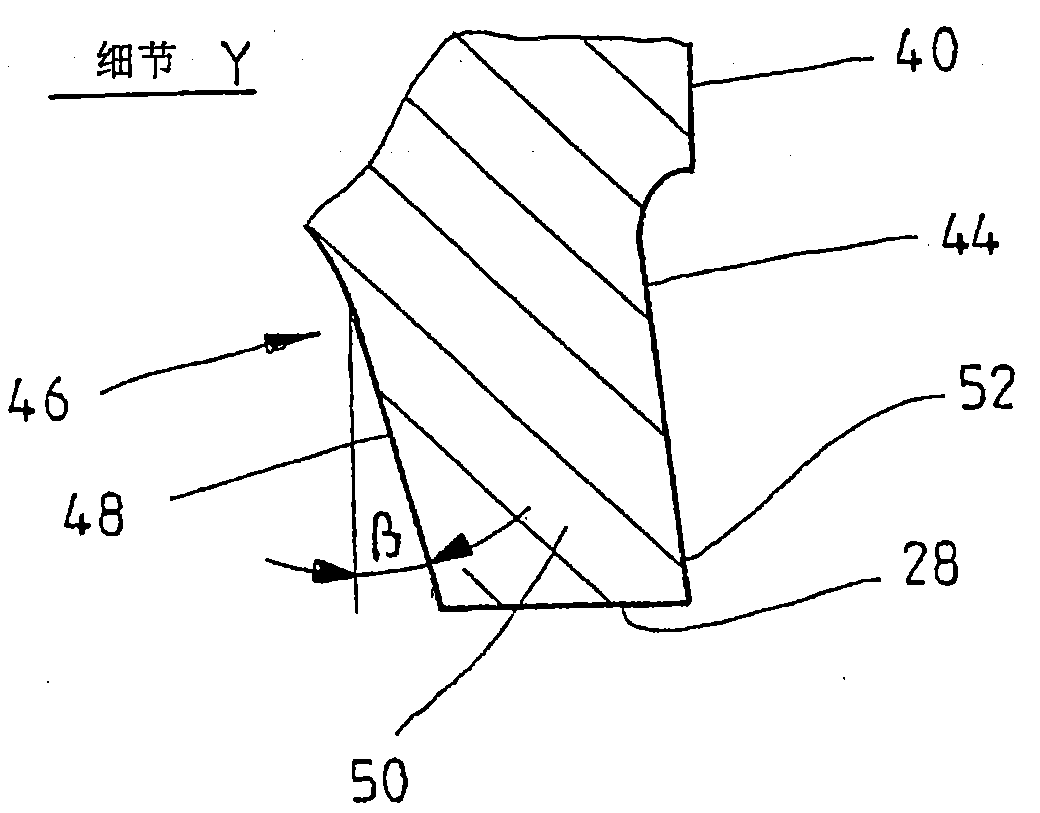

[0025] figure 1 A cross-sectional view of a hydraulic device is shown, eg a motion control block 1 designed as a large plate structure and comprising a disk 2 to which an opposing disk 4 is assigned. A one-way valve 6 is inserted in the disc 2, which, in the locked position shown, blocks the hydraulic fluid flow passage between the inlet A and the outlet passage 8 formed in the opposite disc 4, while the one-way valve 6 is in the locked position shown. The open position controls the connection to open the connection.

[0026] The one-way valve 6 includes a locking element 10 which is biased by a cone 12 against a suitably formed valve seat 14 . The locking element 10 is a hollow piston in which the inner bore 16 opens through an inclined channel 18 in an annular chamber 20 formed by a plurality of dimples on the outer circumference of the locking element 10, each of the inclined holes 18 respectively opening to a dimple. The basic structure of such a locking element 10 is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com