Reciprocating piston type engine

A technology of reciprocating piston and engine, applied in the direction of engine components, combustion engine, engine cooling, etc., can solve the problems of excessive elongation of tension bolts, strong thermal expansion, loss of pre-tightening force of tension bolts, etc., to avoid dew point temperature. Lowering, surface protection, small insulation, small structural weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

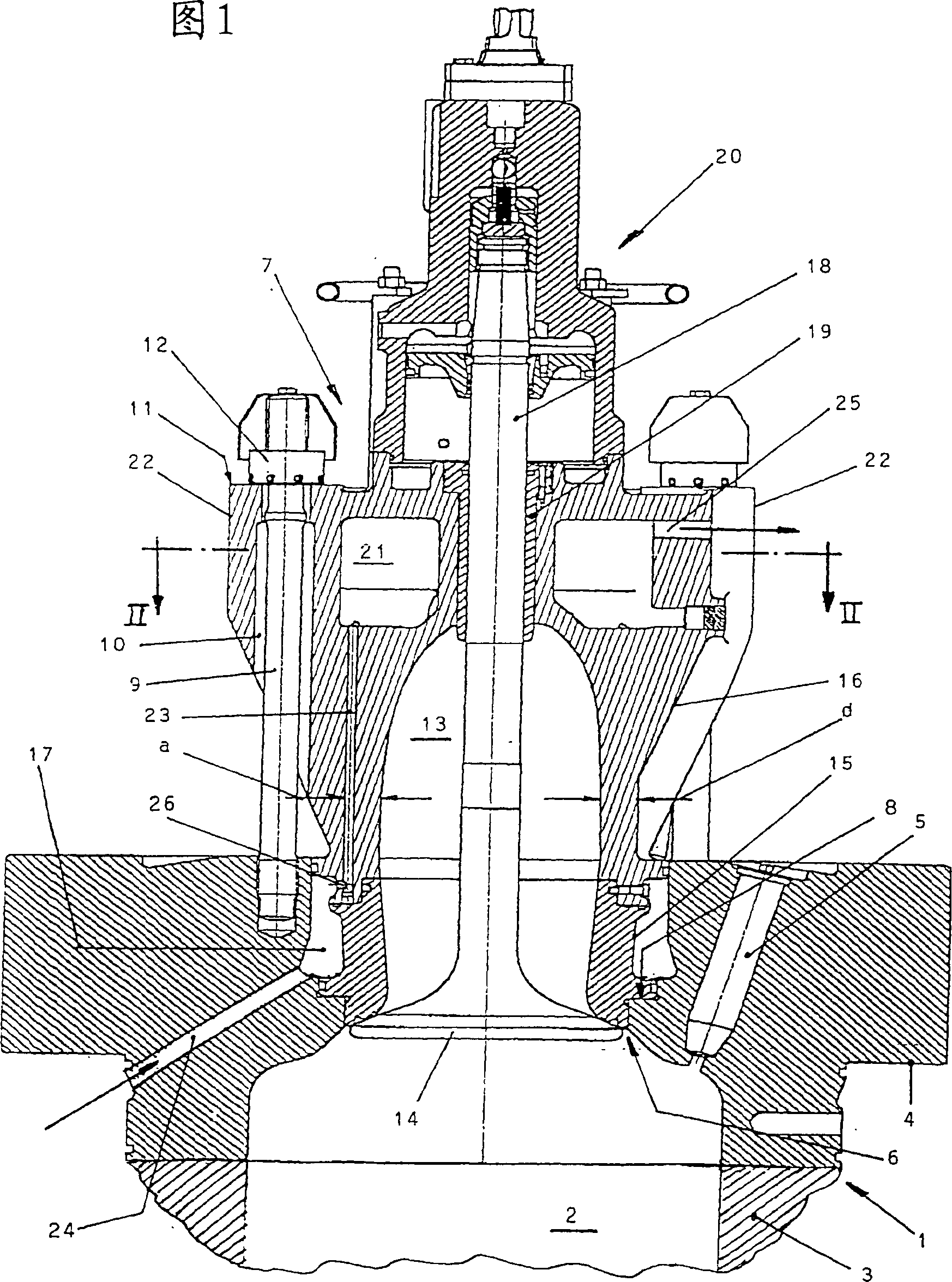

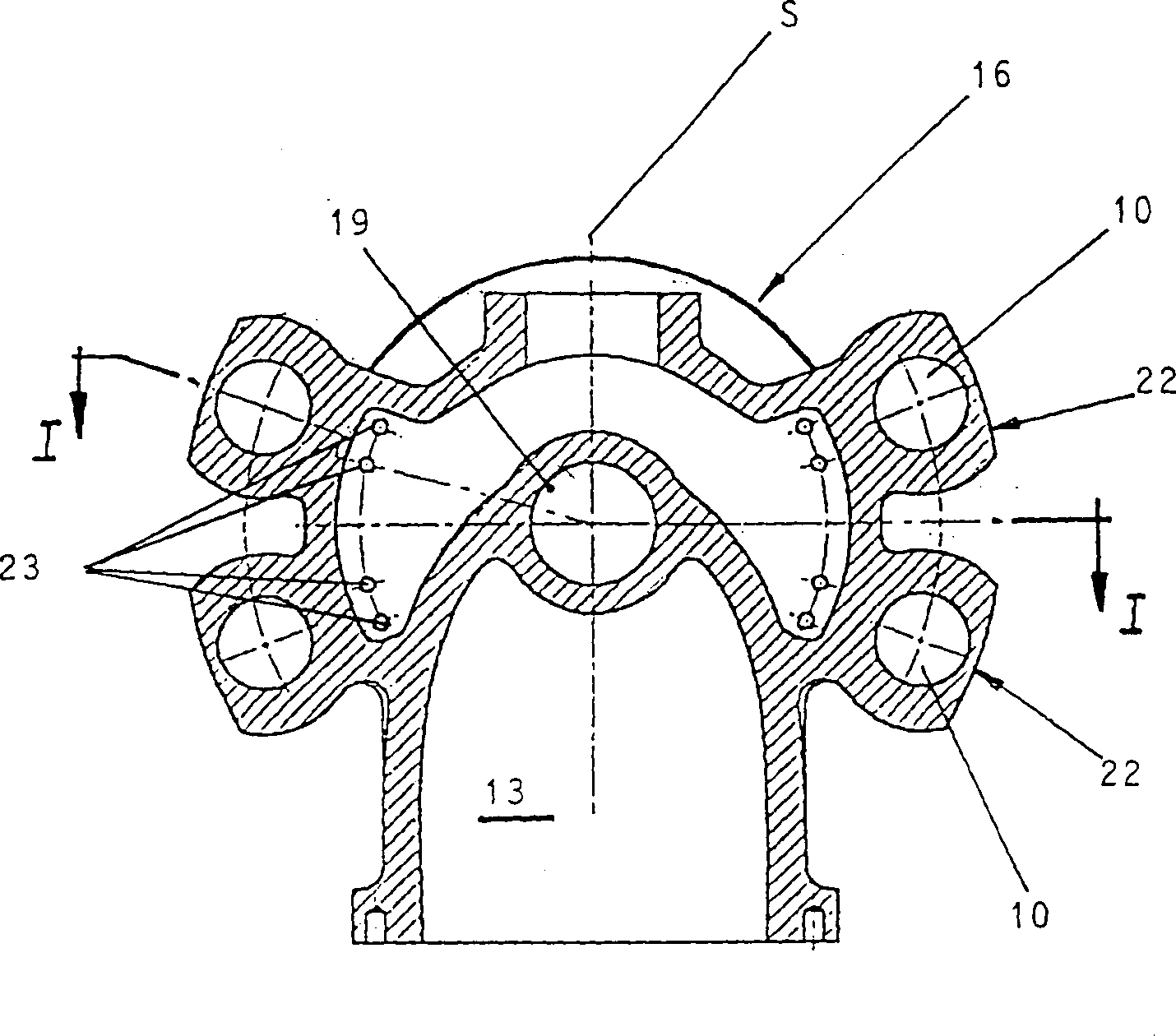

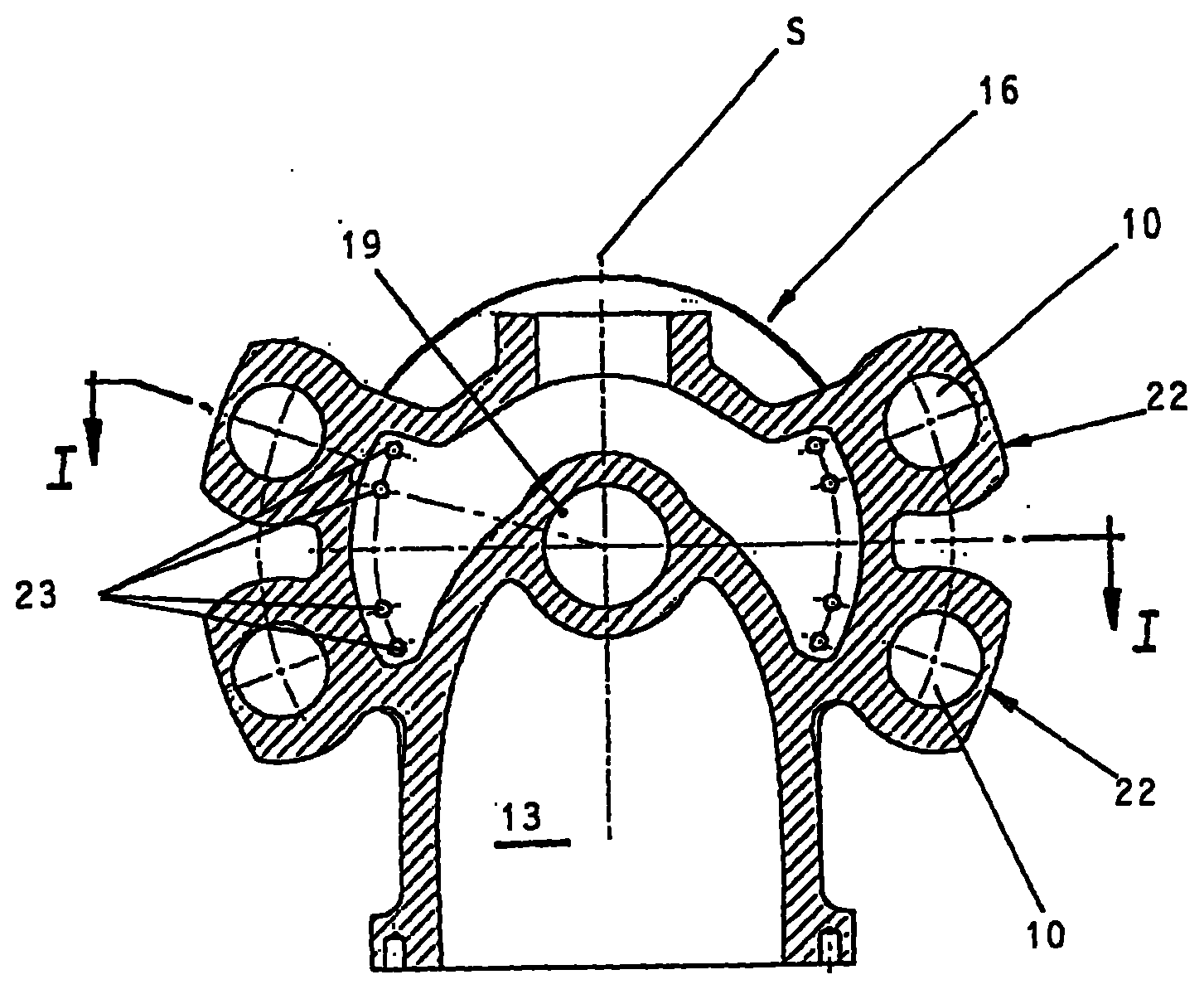

[0014] The basic structure and principle of operation of two-stroke large diesel engines are known per se, so it is not necessary to explain them in greater detail here. Such an engine generally comprises a plurality of cylinders 1 of the type shown in FIG. 1, to which are each assigned a piston, not shown in more detail here, delimiting a combustion chamber, which is connected via a piston rod to a crosshead, and then The latter cooperates with a crankshaft through a connecting rod.

[0015] The cylinder 1 comprises a cylinder liner 3 on which is mounted a cylinder head 4 which accommodates at least one fuel injector 5 and is provided with a central, stepped recess 6 for supporting an exhaust valve housing 7 . The exhaust valve housing 7 engages with its lower part in the groove 6 and bears with a flange-like bearing surface on the bearing surface 8 on the cylinder head formed by the steps of the groove 6 . In order to achieve sufficient pressing force effective in the regio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com