Device for transporting a container

A technology for conveying containers and containers, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as inability to rotate, poor curling results, scratches, etc., and achieve the effect of flexible changes and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

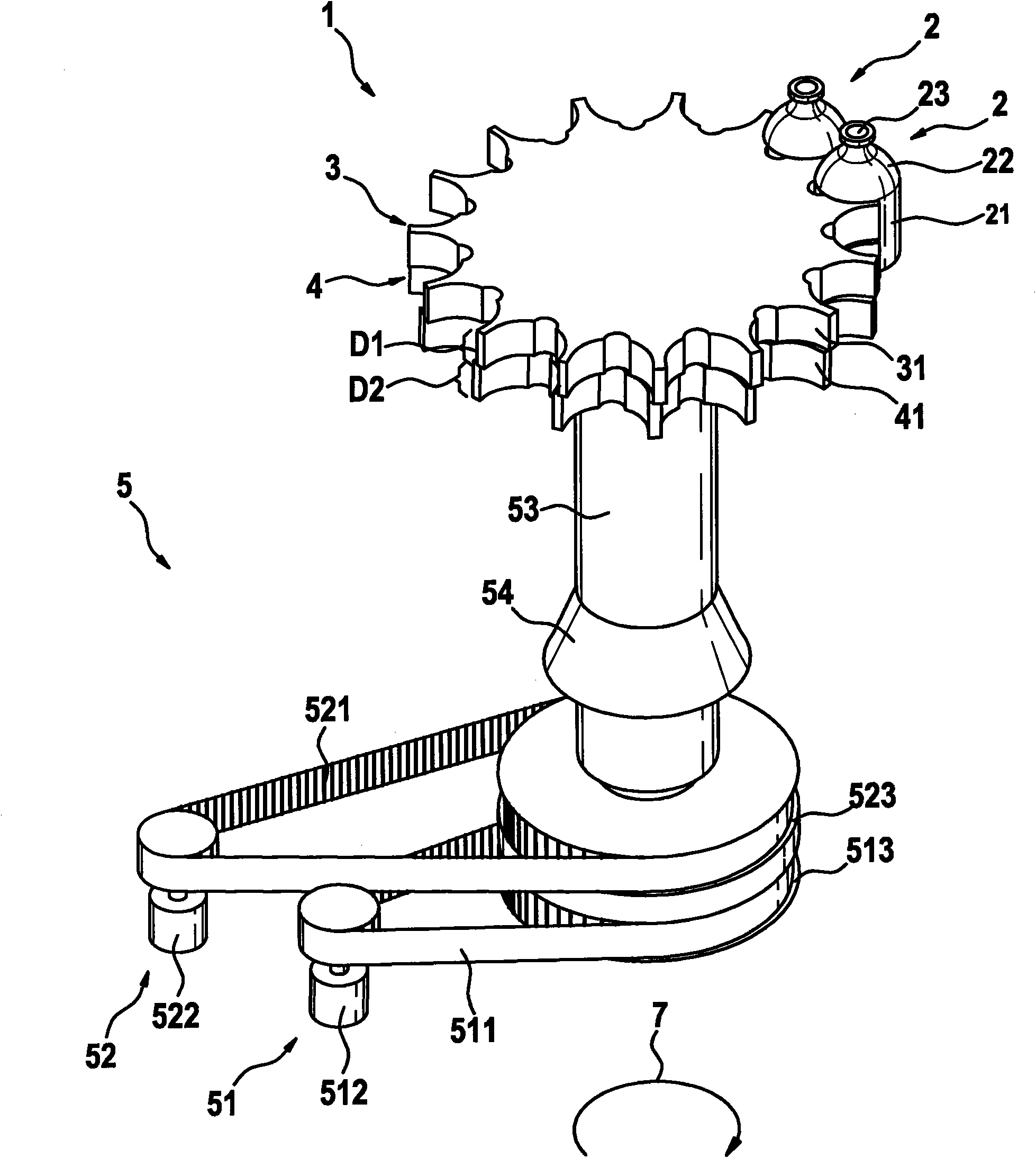

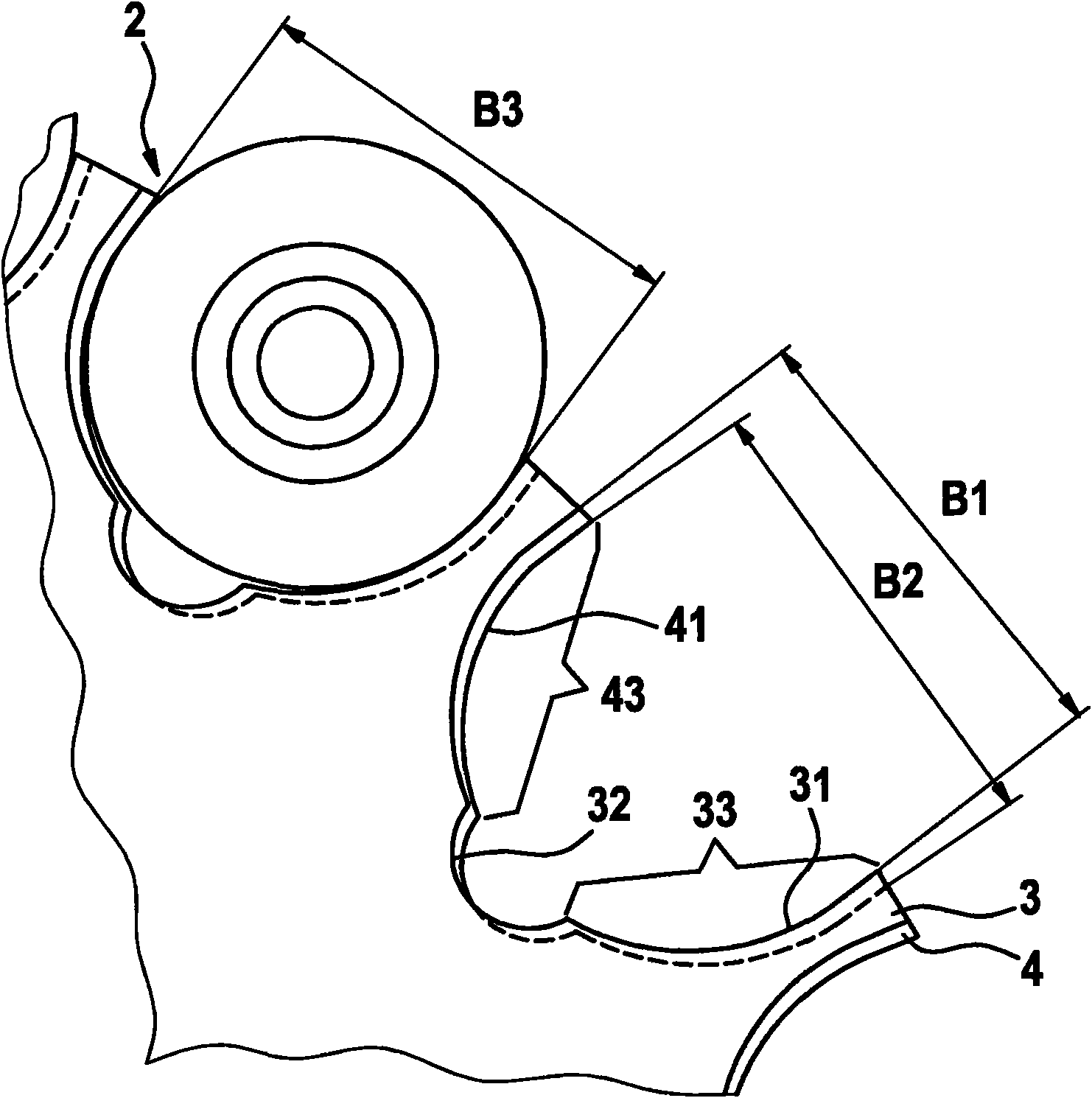

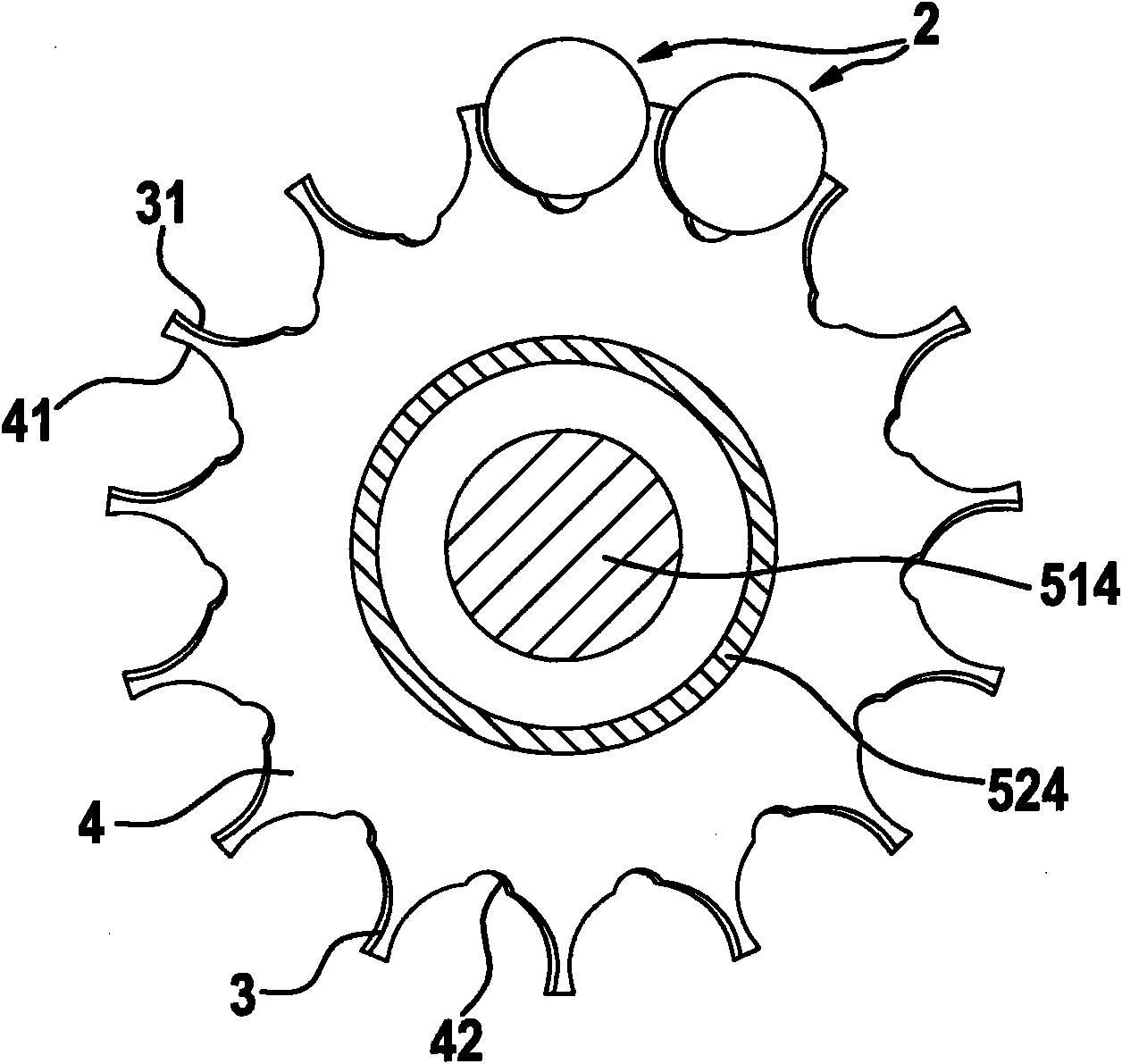

[0022] Refer below Figures 1 to 5 The device 1 for conveying containers 2 according to a preferred embodiment of the present invention is described in detail. The device 1 of this embodiment is used inside a pharmaceutical closure 6 .

[0023] figure 1 A device 1 according to the invention is shown with an upper receiving device and a lower receiving device. These receiving means are embodied as spiders in this exemplary embodiment and are therefore referred to as upper spider 3 and lower spider 4 . The two containers 2 in the upper recess 31 and the lower recess 41 are also seen. A sleeve 53 with an expansion ring 54 extends below the two spiders 3 , 4 . Furthermore, the first drive 51 and the second drive 52 are seen. Also shown is an arrow 7 which predetermines the direction of rotation of the device 1 according to the invention.

[0024] The container 2 is composed of a cylindrical container body 21 , a narrowing portion 22 and an opening 23 respectively.

[0025] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com