Electric brake system for a vehicle

A technology for electric braking and vehicles, applied in braking control systems, road vehicle drive control systems, brakes, etc., can solve problems such as abnormal relay units, achieve easy monitoring, reduce hysteresis, and improve charging characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

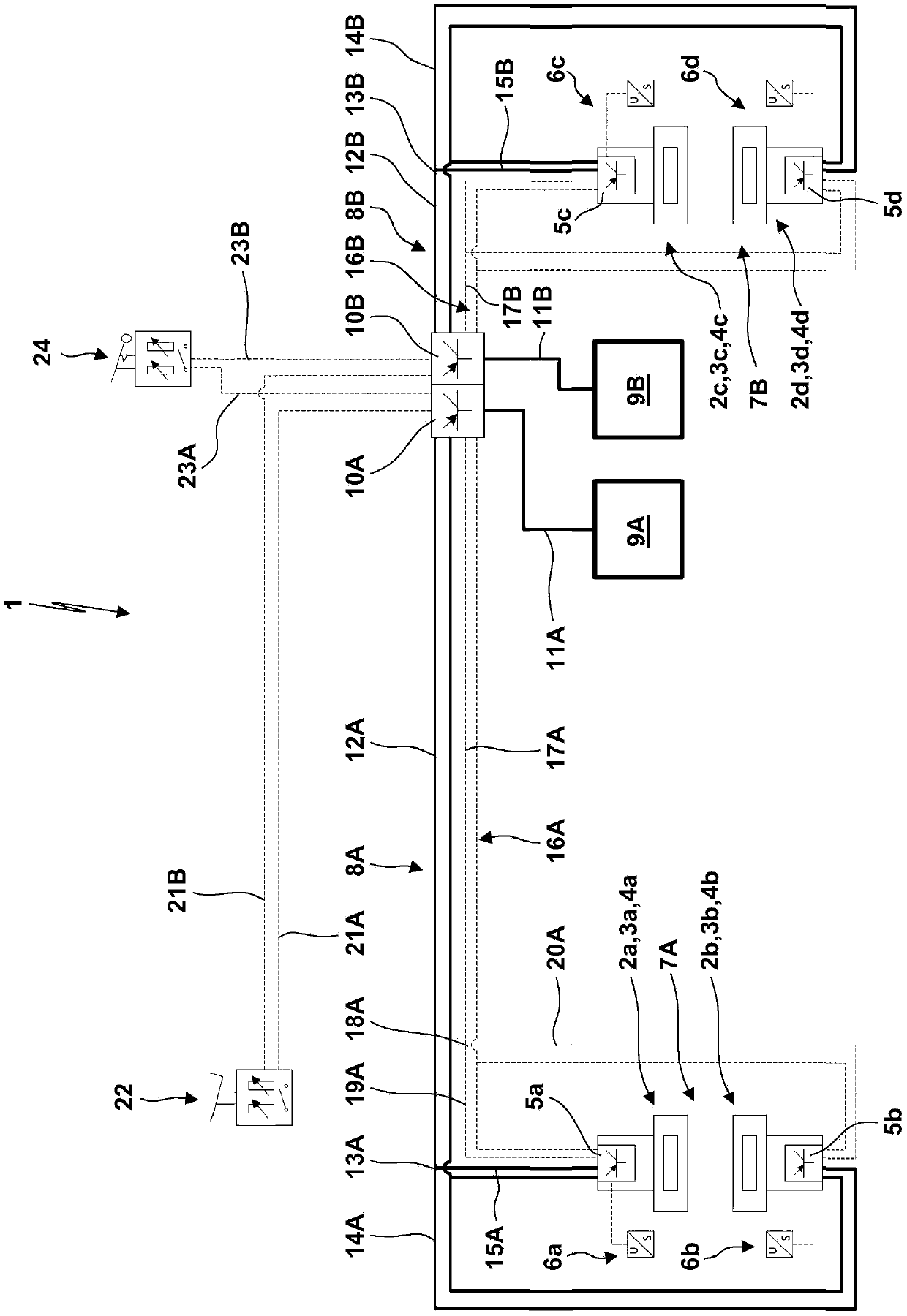

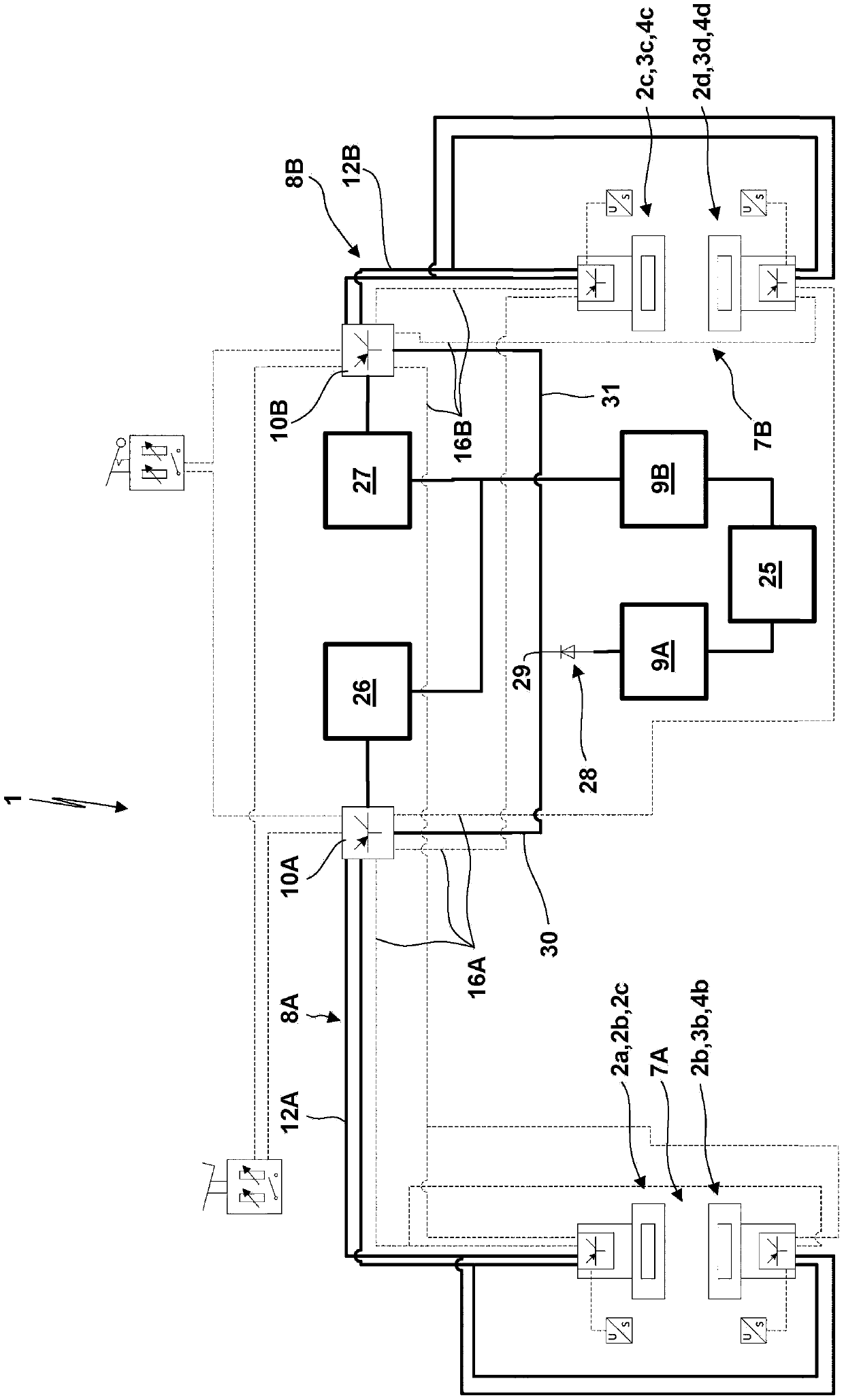

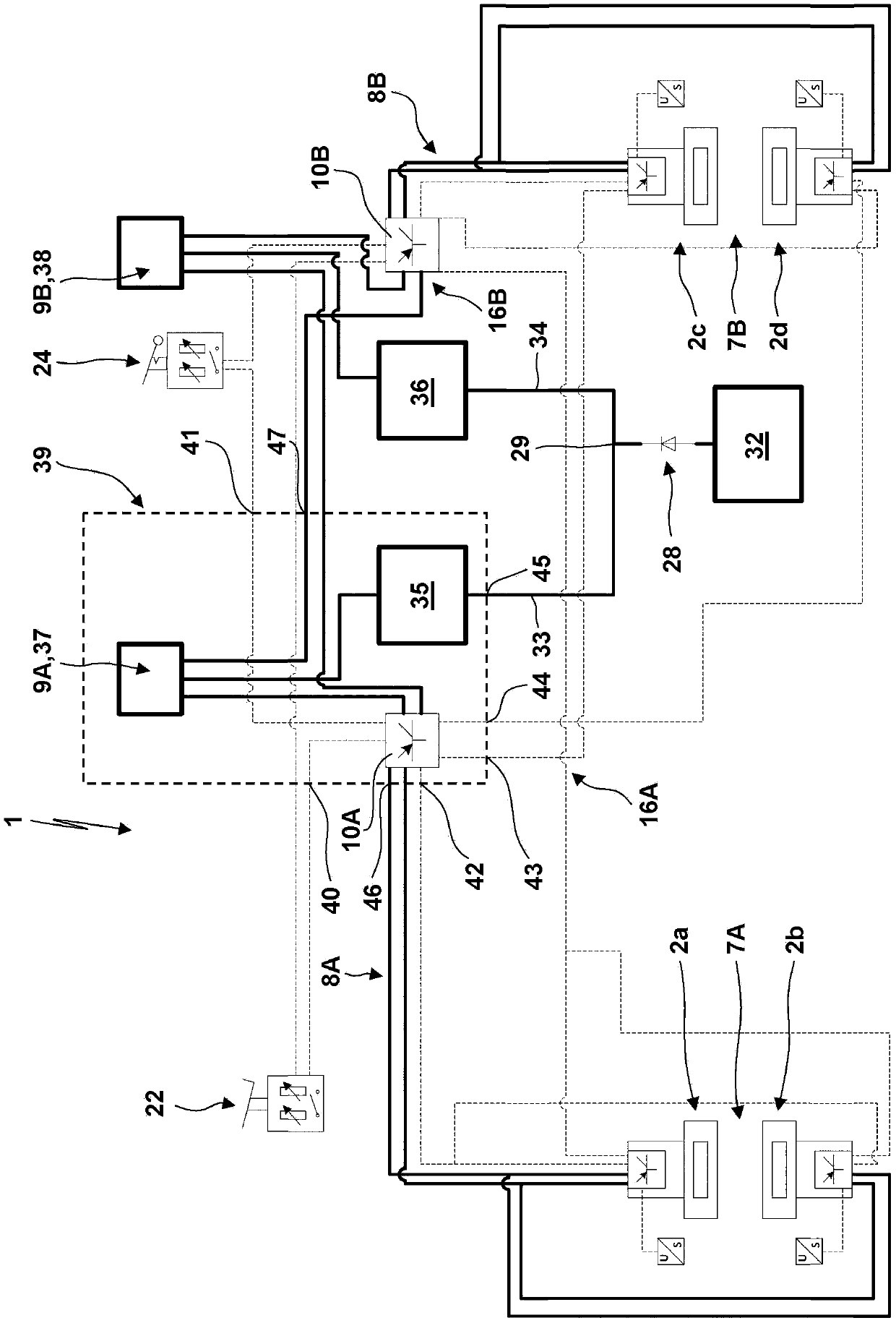

[0093] In the figures, the same reference numerals are used for components having the same or equivalent function and / or design. If the same parts are used several times in an embodiment, these parts are marked with the same reference numerals and an additional distinguishing letter a, b, c, . . . or A, B. The use of a reference number in the following description without distinguishing letters a, b, c, ... or A, B may refer to all parts with this reference number, or to only a single part or any number of these parts. If the same component or component group is used multiple times for an embodiment, only one of these components or component groups will be described in some cases. In this case, however, the other components or groups of components apply correspondingly.

[0094] figure 1 An electric braking system 1 is shown. The electric braking system 1 comprises four braking devices 2a-2d. The brake devices 2a-2d respectively comprise brake actuators 3a-3d respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com