Disposable assembly molding processing method for split traffic barricade

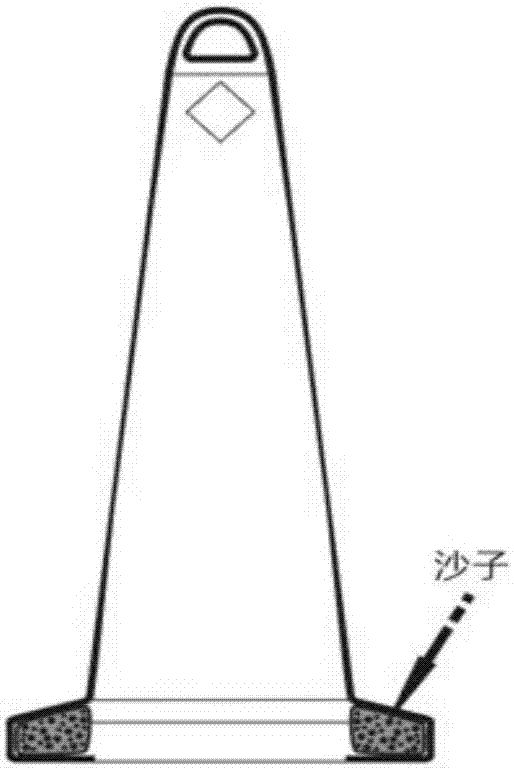

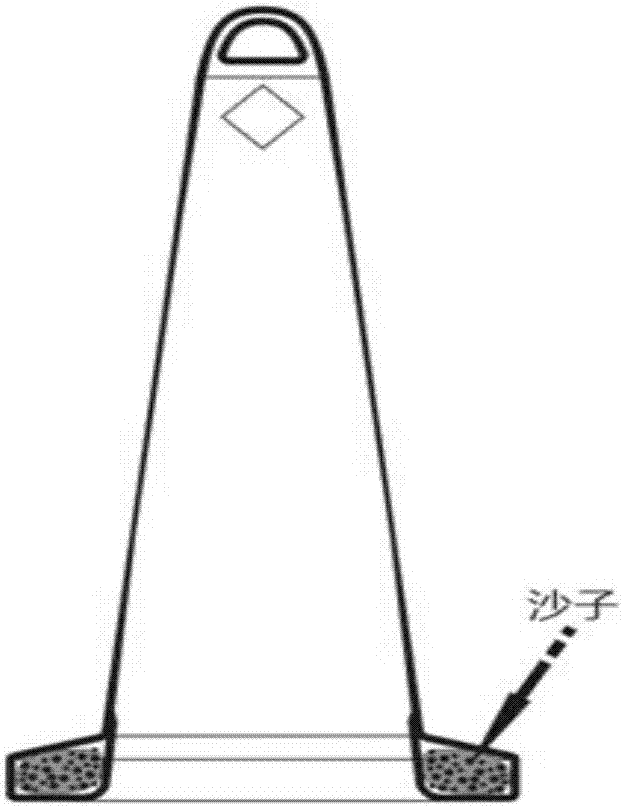

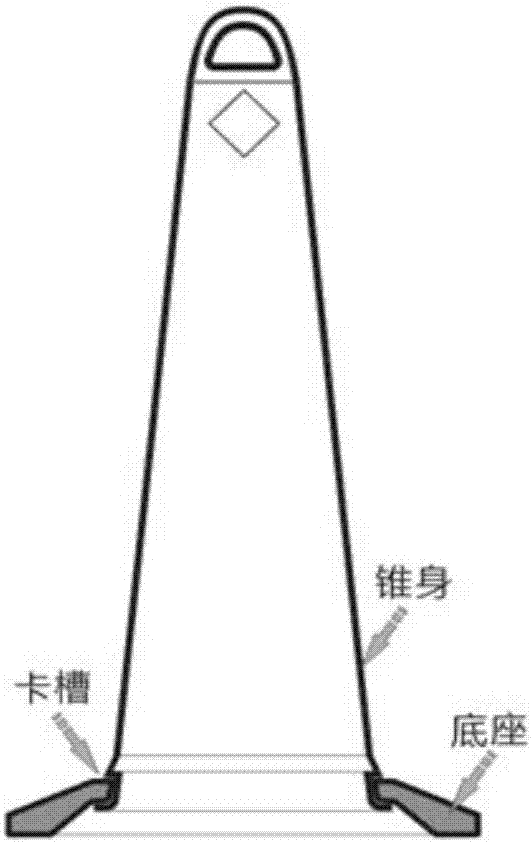

A technology of forming processing and processing method, which is applied in the field of road safety protection equipment processing, can solve the problems of separation of cone and base, many processing steps, sand leakage, etc., and achieves the effect of firm bonding, reduction of production cost, and reduction of assembly work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A one-time assembly and molding processing method of a split traffic barricade, the processing method specifically includes the following steps (see flow chart Figure 5 ):

[0039] (1) Selection of raw materials: select high-density polyethylene (HDPE) as raw material, and dry it;

[0040] (2) Clean the mold: clean the inner core of the mold with gauze, and then spray a layer of release agent silicone methyl branched chain silicone oil on the inner core;

[0041](3) Pre-softening: Dry and pre-soften the raw materials. The temperature for drying the raw materials is 75°C for 3 hours. The purpose of drying is to remove moisture and moisture in the raw materials; the temperature for screw heating and plasticizing is 145°C, considering the production cost comprehensively, an extruder with a screw diameter of 90 mm is used.

[0042] (4) The existing base is placed on the bottom of the upper mold, and the extruder extrudes a semi-molten tube blank, passes through the base,...

Embodiment 2

[0049] A one-time assembly and molding processing method of a split traffic barricade, the processing method specifically includes the following steps:

[0050] (1) Selection of raw materials: select high-density polyethylene as a raw material, dry it, and put it into the hopper of the extruder;

[0051] (2) Clean the mold: clean the inner core of the mold with gauze, and then spray a layer of release agent methyl silicone oil on the inner core;

[0052] (3) Pre-softening: Dry and pre-soften the raw materials; the temperature of raw material drying is 80°C, and the time is generally 2 hours. The purpose of drying is to remove moisture and moisture in the raw materials; the temperature of screw heating and plasticization The temperature is 160°C; the heating and plasticizing time depends on the size of the screw. Considering the production cost comprehensively, an extruder with a screw diameter of 120mm is used.

[0053] (4) The existing base is placed on the bottom of the upp...

Embodiment 3

[0059] A one-time assembly and molding processing method for split traffic roadblocks, specifically comprising the following steps:

[0060] (1) Selection of raw materials: select high-density polyethylene as a raw material, dry it, and put it into the hopper of the extruder;

[0061] (2) Cleaning the mold: clean the inner core of the mold with gauze, and then spray a layer of release agent silicone methyl branched chain silicone oil on the inner core;

[0062] (3) Pre-softening: drying and pre-softening the raw materials; the drying temperature of the raw materials is 85°C, and the time is 1h. The purpose of drying is to remove the moisture and moisture in the raw materials; the temperature of the screw heating and plasticizing is 185°C, the time of heating and plasticizing depends on the size of the screw. Considering the production cost comprehensively, an extruder with a screw size of 120mm in diameter is used.

[0063] (4) The existing base is placed on the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com