Single-machine single-pump electric drive fracturing semitrailer

A semi-trailer, single-pump technology, applied in motor vehicles, tractor-trailer combinations, pumps, etc., can solve problems such as high maintenance costs for engines and gearboxes, affecting the normal life of surrounding residents, and engine exhaust pollution and noise. It is convenient for well site layout, ensuring high-load operation and good support stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

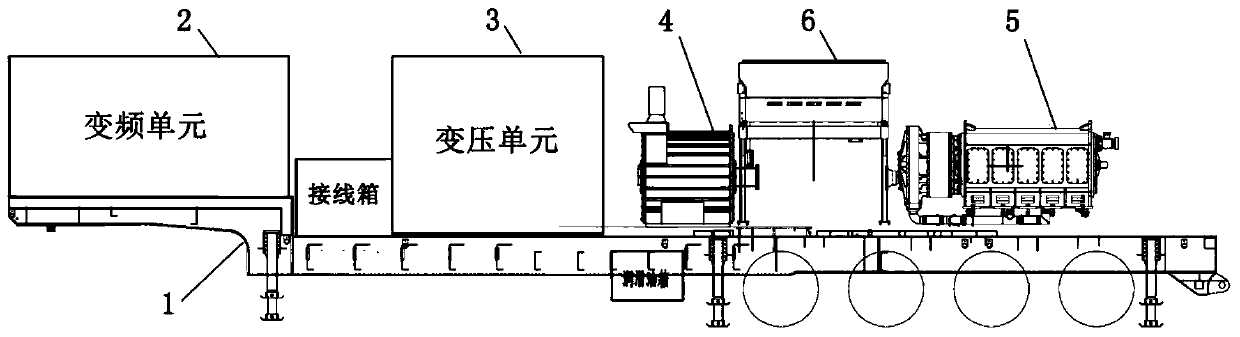

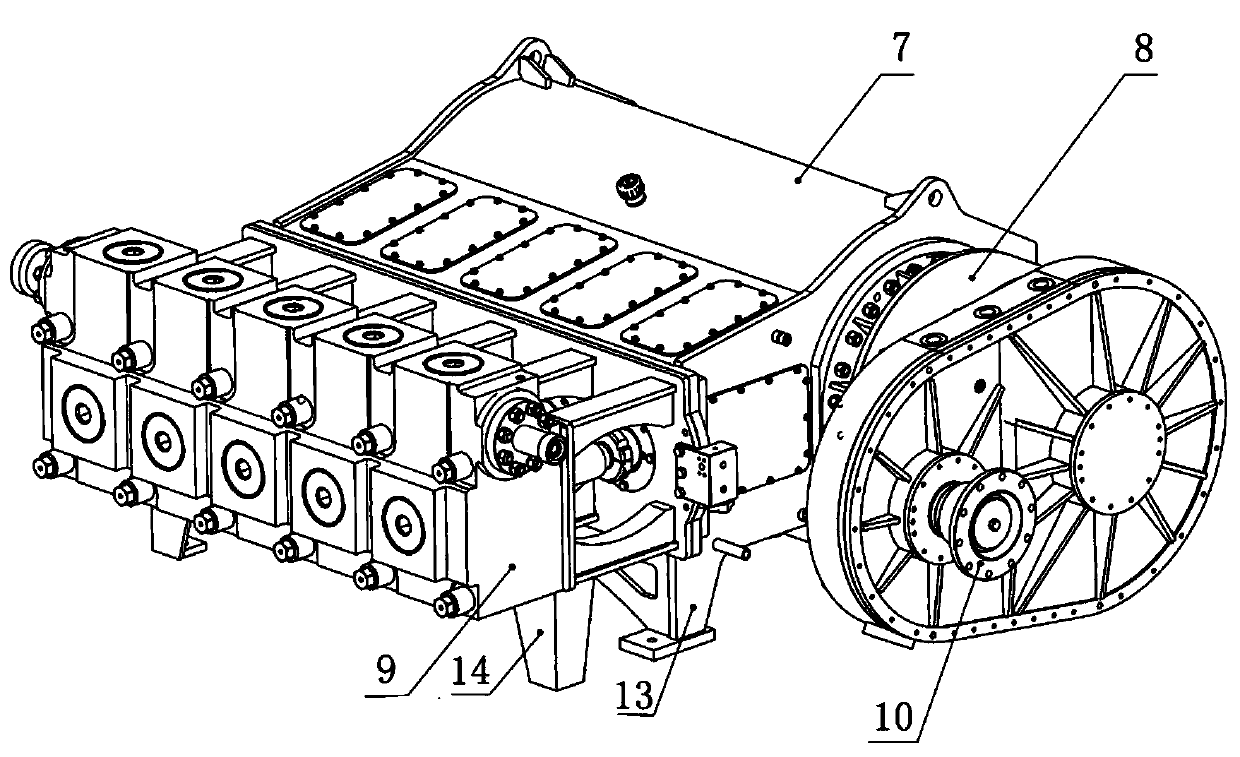

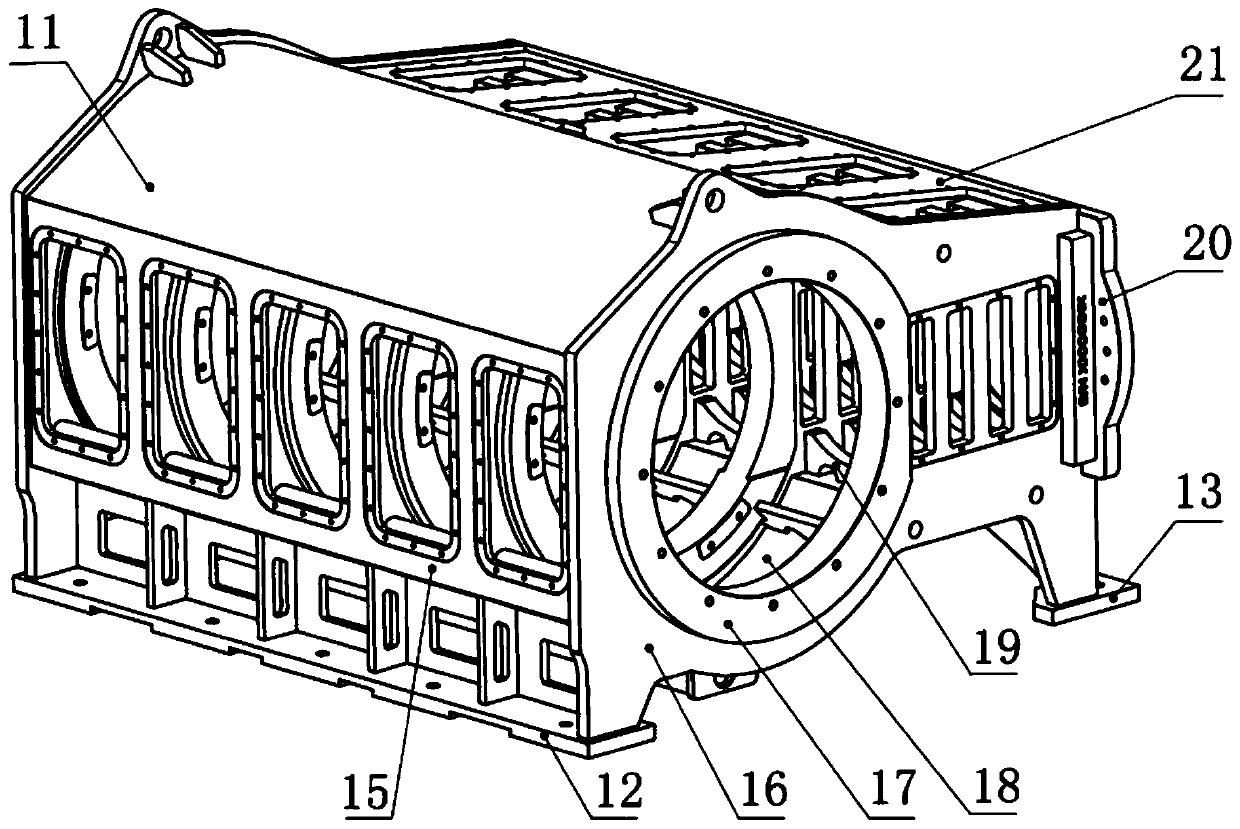

[0031] Examples such as Figures 1 to 3 As shown, a single-machine single-pump electric drive fracturing semi-trailer includes a semi-trailer body 1, a plunger pump 5, a radiator 6, a power supply unit and a motor 4, the power supply unit, the motor 4, a radiator 6 and a plunger The pump 5 is integrated on the semi-trailer body 1, the motor 4 is one, the radiator 6 is one, the plunger pump 5 is one, the power supply unit provides power for the motor 4, the motor 4 is connected to the plunger pump 5, and the radiator 6 provides cooling for the lubricating oil of the plunger pump 5. The power supply unit includes a voltage conversion unit 3 and a frequency conversion unit 2, the frequency conversion unit 2 is connected to the voltage conversion unit 3, the voltage conversion unit 3 is arranged at one end of the semi-trailer body 1 close to the motor 4, and the frequency conversion unit 2 is set On the gooseneck of the semi-trailer body 1. The number of axles of the semi-traile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com