Rankine cycle system and fluid working medium material construction method thereof

A technology of fluid working medium and circulation system, which is applied in steam engine devices, special data processing applications, instruments, etc., can solve immature problems, achieve the effects of improving thermophysical properties, reducing heat energy loss, and improving cycle thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

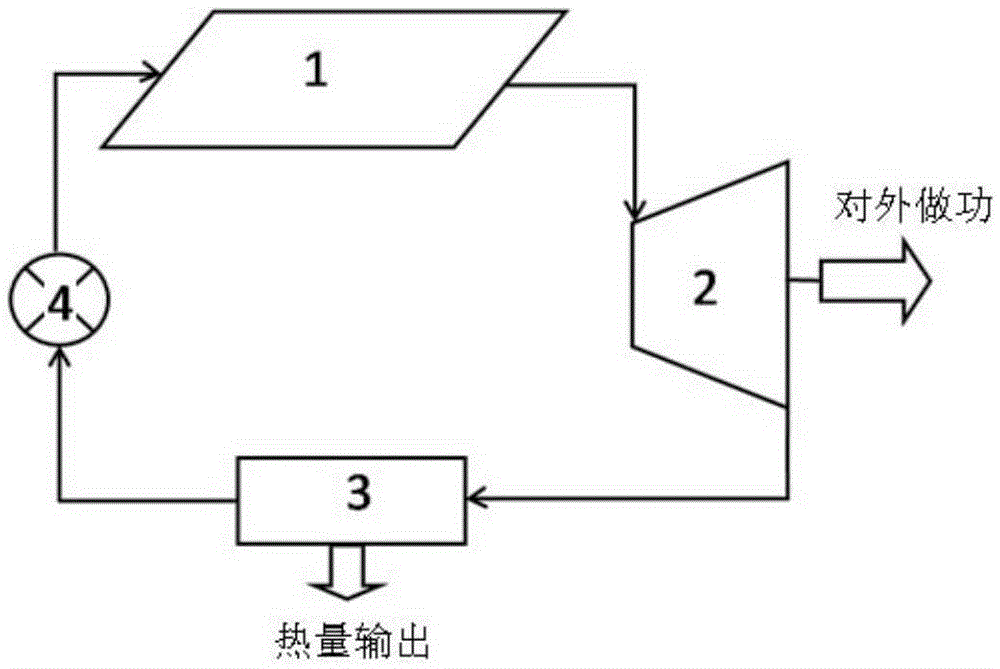

[0026] Such as figure 1As shown, the single-stage Rankine cycle system includes an evaporator 1, a first steam turbine 2, a condenser 3, and a pressure pump 4. The steam turbine 2 works externally, and the fluid working medium from the first steam turbine 2 enters the condenser 3 to be further condensed to a saturated state, and the condenser 3 outputs and utilizes the heat released by the fluid working medium in the condenser 3 . The fluid working medium condensed to saturated state is then compressed by the pressure pump 4 and returned to the evaporator 1 to complete a cycle process.

[0027] The construction method of the fluid working fluid material of the single-stage Rankine cycle system comprises the following steps:

[0028] 1) Based on the principle of thermal power generation cycle and the principle of thermal physical properties of compounds, select groups with high contribution to the safety of fluid working fluids and small contribution to pollution to establish ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com