Gasoline engine EGR stratified charge system based on flow guiding plate

A stratified air intake, gasoline engine technology, applied in charging systems, mechanical equipment, engine components, etc., can solve problems such as low EGR tolerance, duct introduction affecting the charging coefficient, and difficulty in realizing EGR tumble stratification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

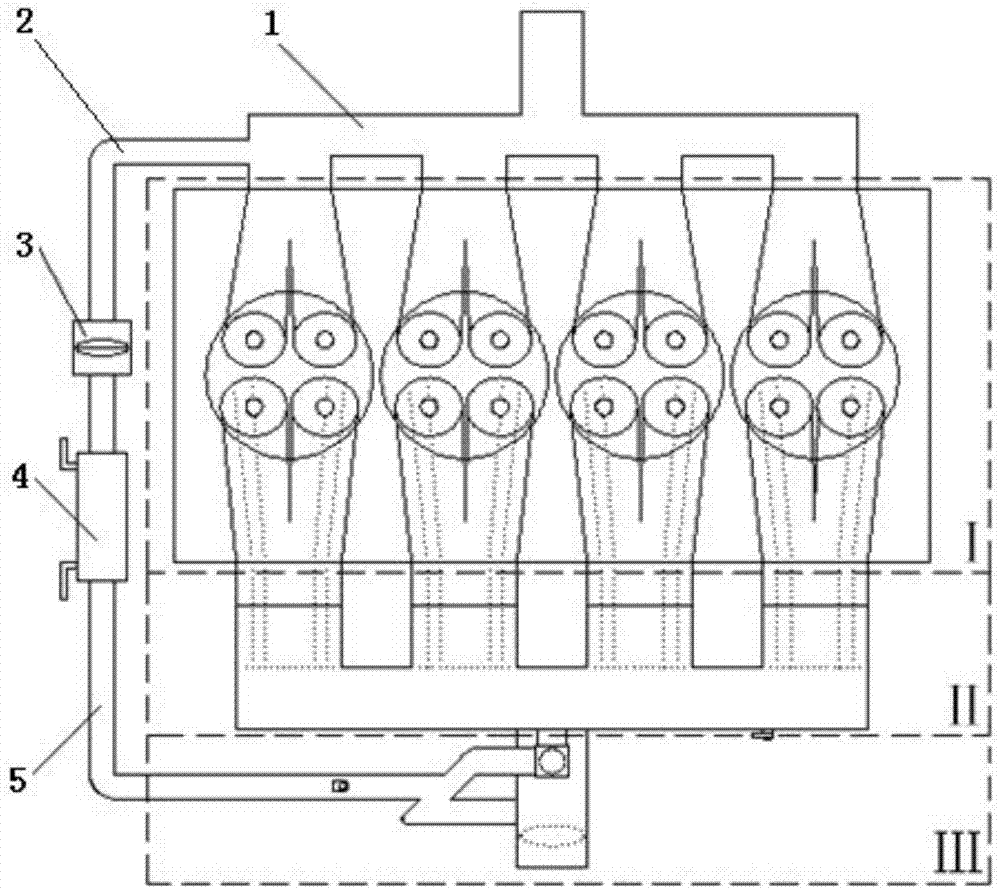

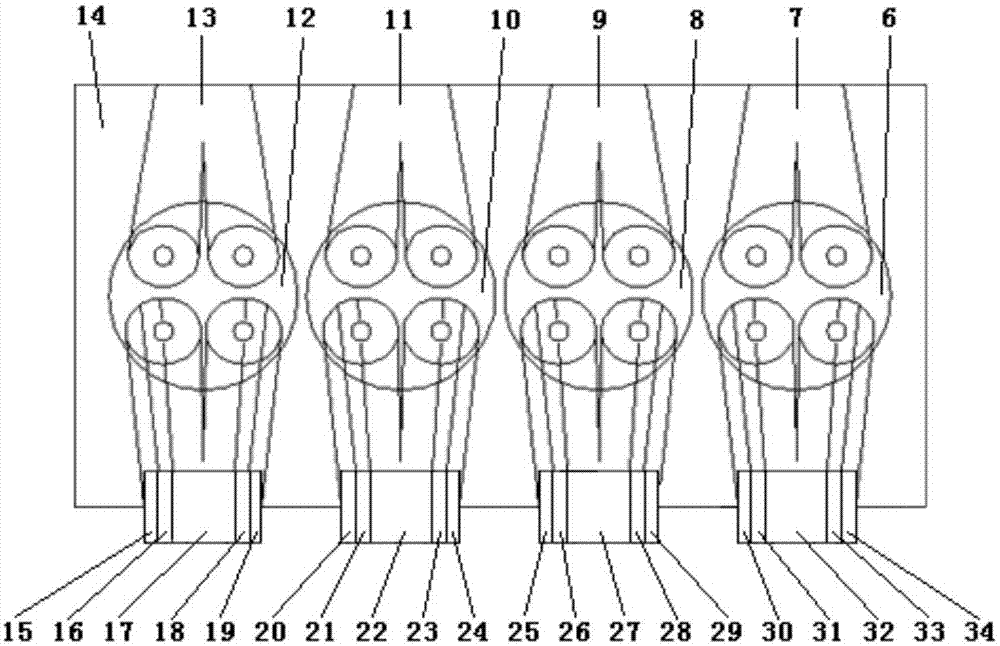

[0053] The present invention is described in detail below in conjunction with accompanying drawing:

[0054] The exhaust pipe 1 is an exhaust pipe for an ordinary four-cylinder gasoline engine, and is installed on the exhaust port side of the cylinder head part I. Each manifold of the exhaust pipe 1 corresponds to the exhaust port of the cylinder head one by one, and the exhaust Tube 1 is generally cast iron material.

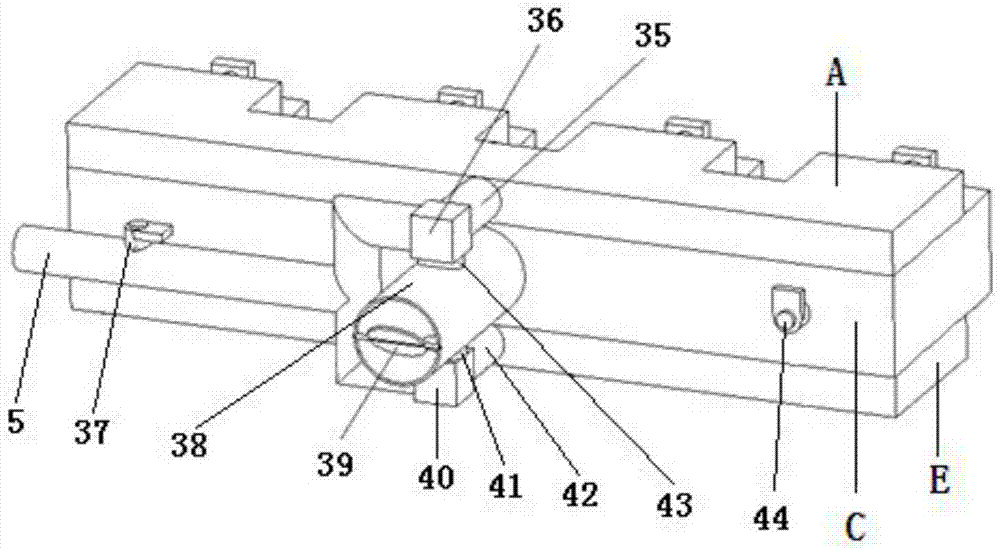

[0055] The EGR valve 3 is connected in series in the EGR circuit 5, before the EGR cooler 4, and is used to control the amount of EGR introduced into the intake system, and is used in conjunction with the EGR circuit pressure sensor 37 and the fresh air pressure sensor 44 to ensure that the Exhaust gas pressure and fresh air pressure are equal.

[0056] The EGR cooler 4 is a water-cooled EGR cooler, which is connected in series in the EGR circuit 5, and the rear end of the EGR valve 3 is equipped with a cooling water interface in and out, and the EGR temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com