Gas compressor dual drive mechanism

a gas compressor and drive mechanism technology, applied in the direction of positive displacement liquid engine, pump, machine/engine, etc., can solve the problems of less practicability of electric motor driven compressors, increased reserve or peak load demand, and increased cost in most cases, so as to increase redundancy and increase efficiency. production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

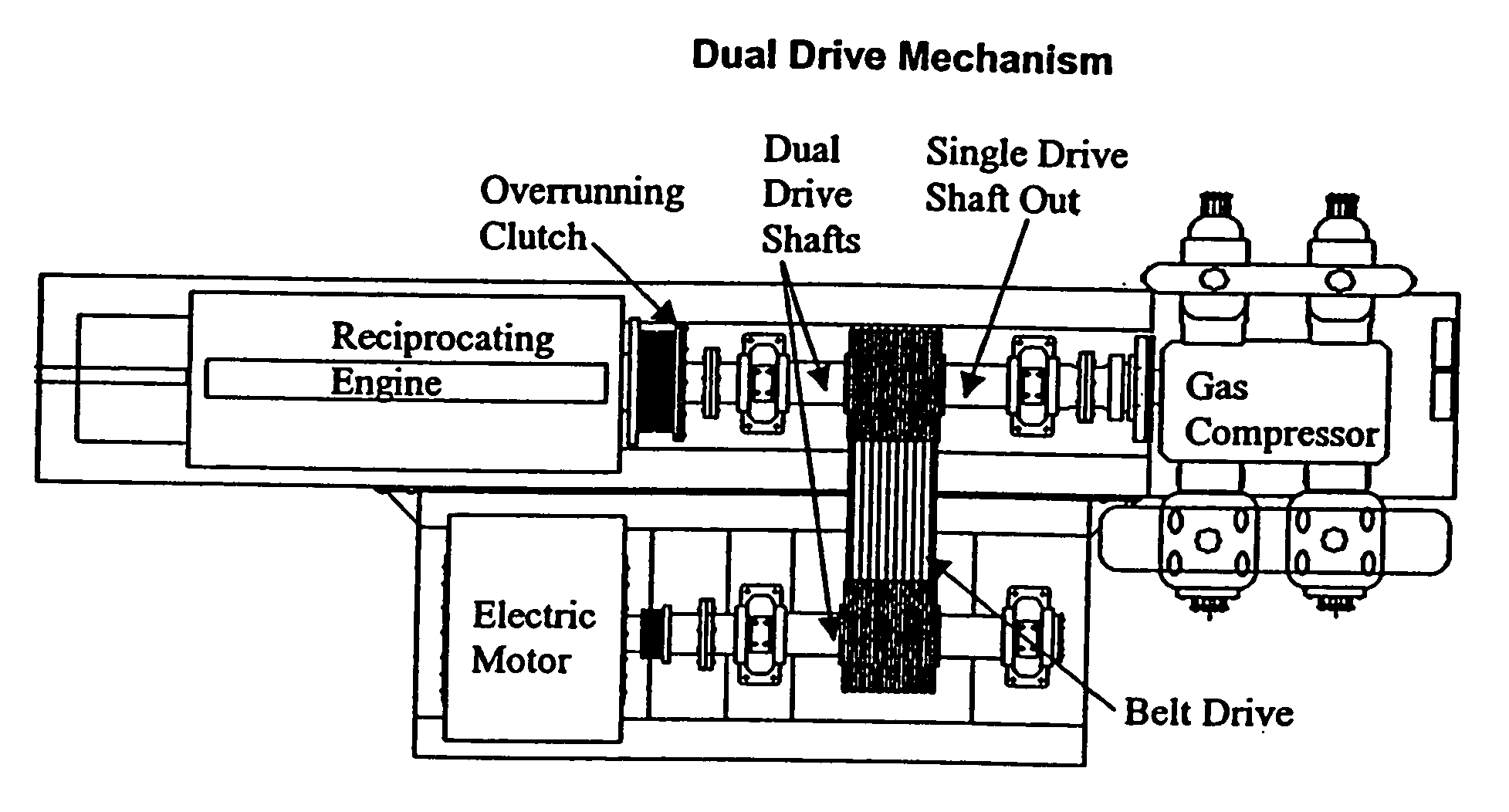

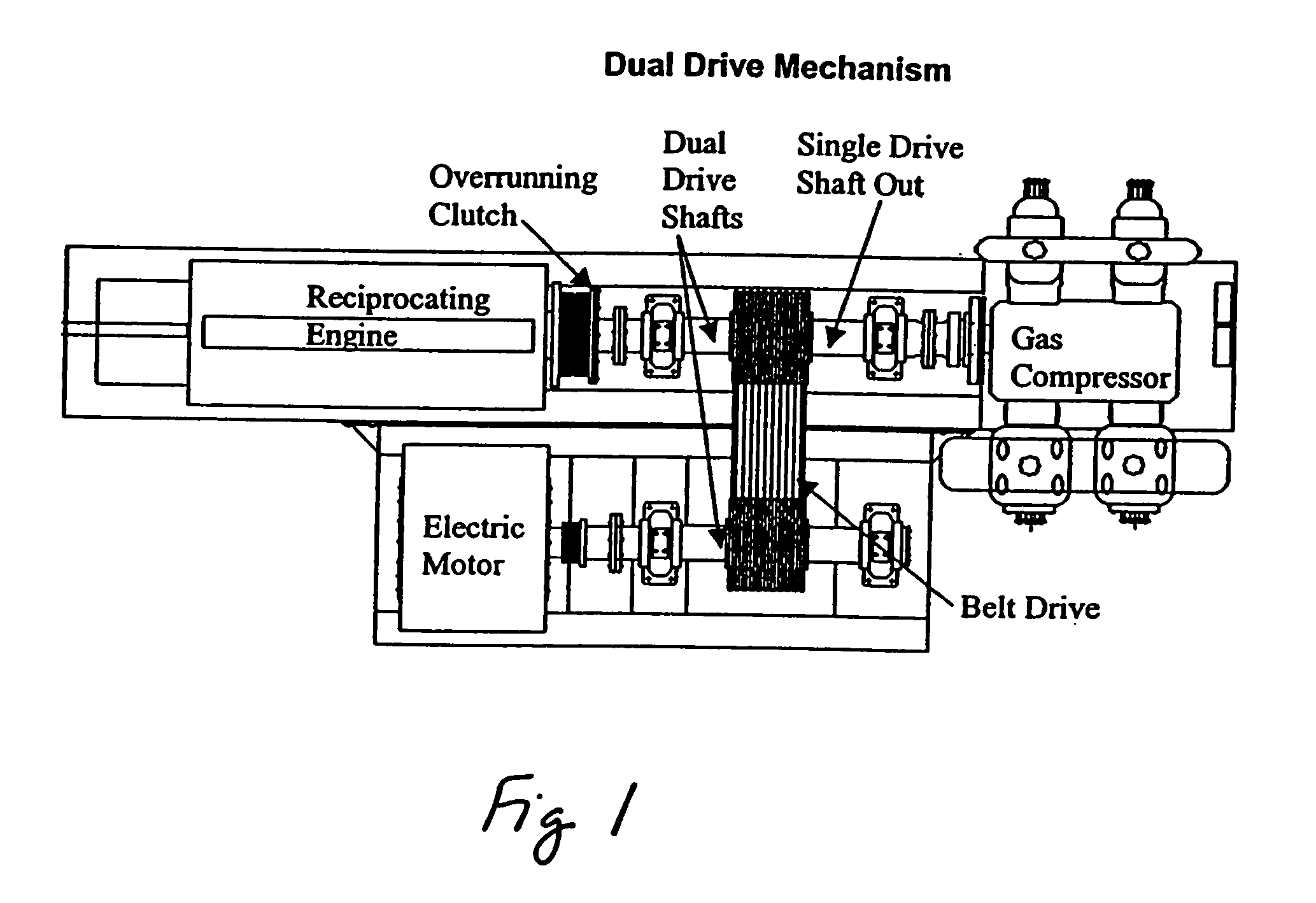

[0018] A dual drive mechanism for a gas compressor is used in the gathering of natural gas. The dual drive mechanism can be used in other industries and for other applications in addition to the natural gas and oil industries. The dual drive mechanism can be used to drive a single gas compressor or a plurality of gas compressors, as will be apparent according to the description below.

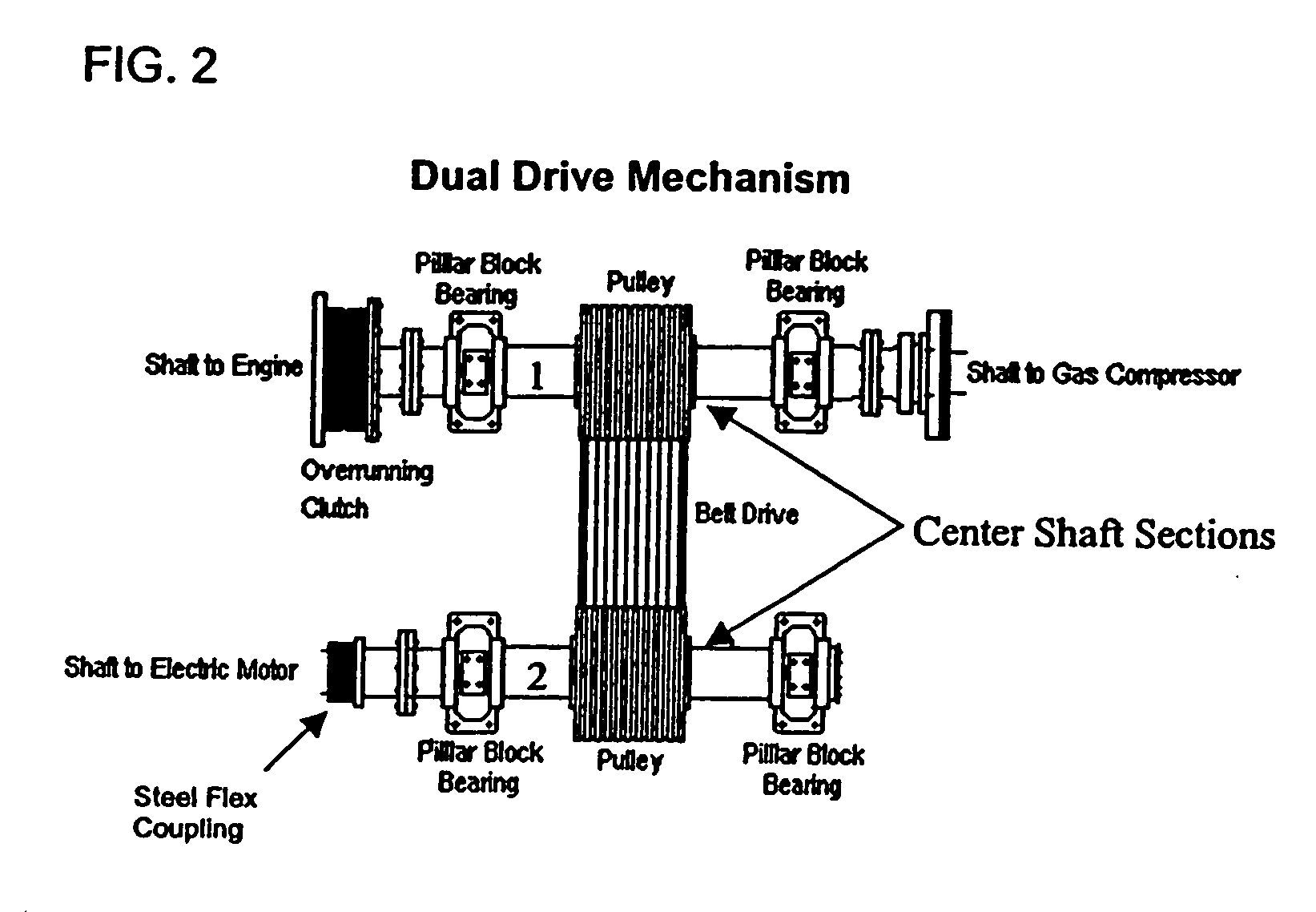

[0019] A dual drive mechanism for use in driving a gas compressor includes a twin shaft drive mechanism. With reference to FIG. 1, it is shown that the twin drive mechanism effectively transfers the physical shaft break horsepower of either an engine or an electric motor to a single shaft drive of a gas compressor. FIG. 1 shows an engine crankshaft and a compressor crankshaft that share the same centerline. The engine is equipped with a weighted flywheel (sized from torsional analysis) and an overrunning clutch assembly. With continued reference to FIG. 1 and referring to FIG. 2, the engine drive shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com