Compressor inter-stage temperature control

a compressor and temperature control technology, applied in mechanical equipment, refrigeration components, light and heating equipment, etc., can solve the problems of condensation of vapor and formation of recycle loops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

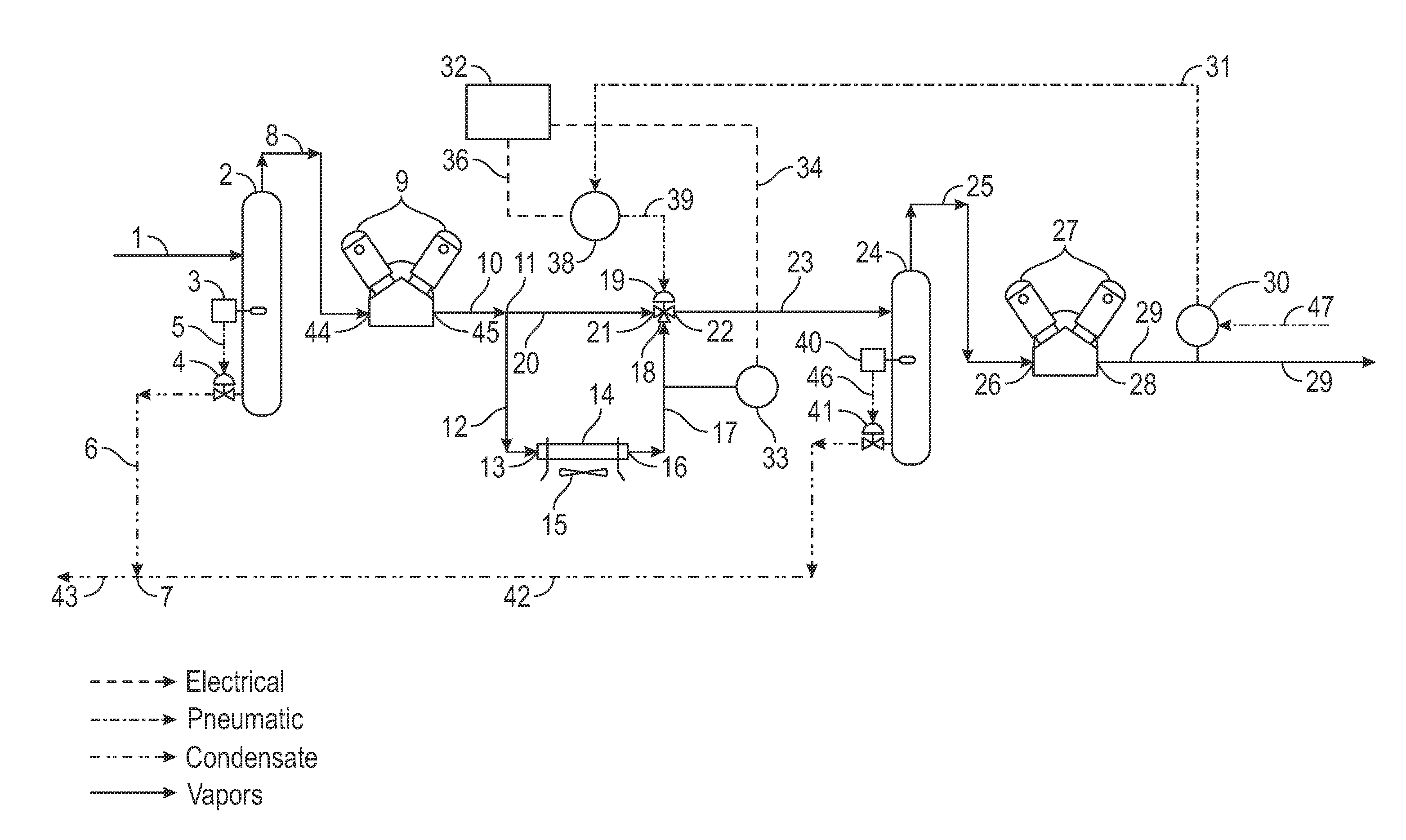

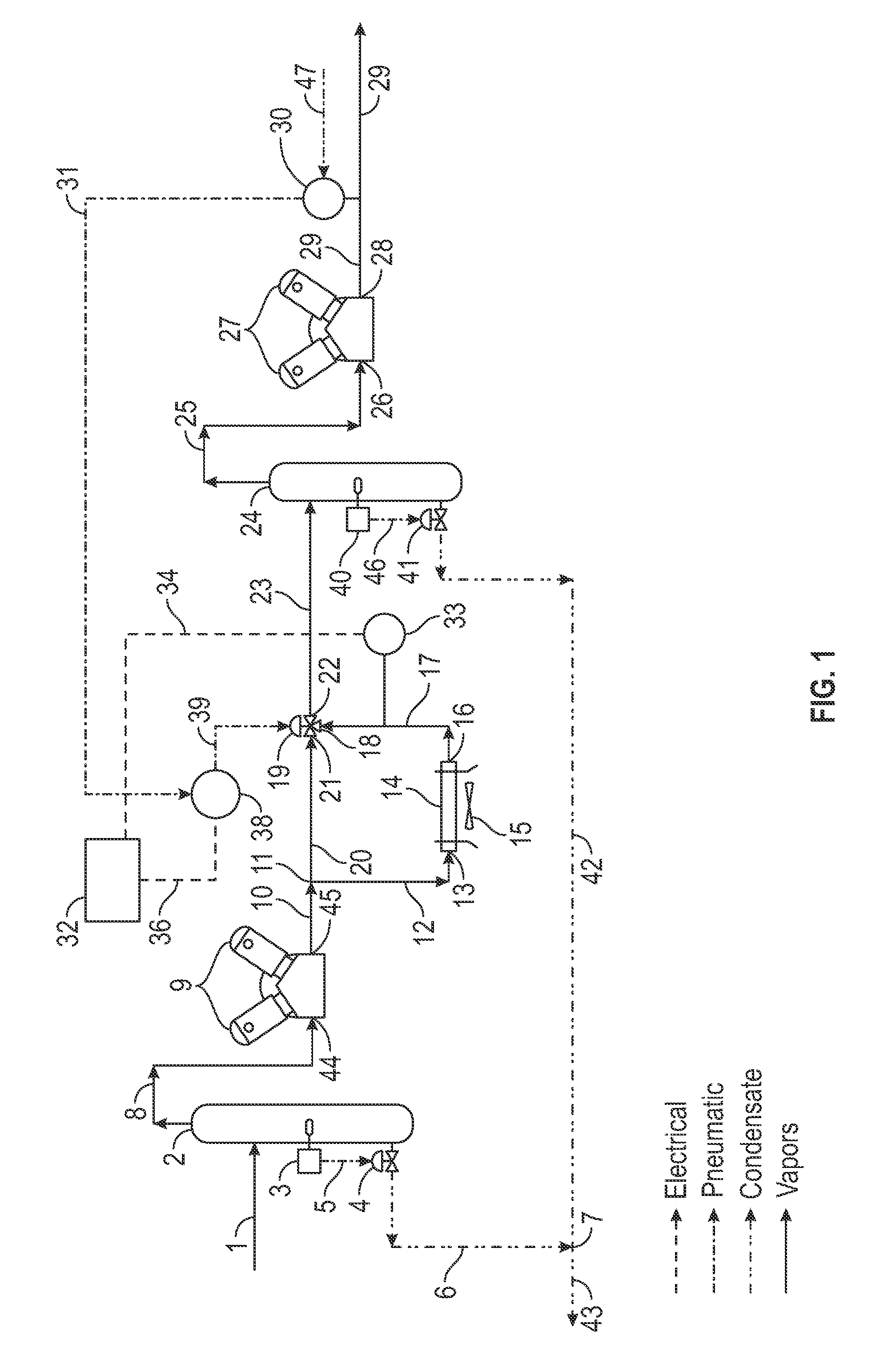

[0008]An embodiment of the present invention relates to a method for regulating temperature of a gas between stages of compression which includes providing a control valve between stages of compression; providing an air-cooled heat exchanger; monitoring the temperature of the gas in at least one location; and manipulating the control valve such that at least a portion of compressed gas from a first stage of compression can be selectively caused to flow through the air-cooled heat exchanger before being introduced into a second stage of compression. The at least one location can be downstream of an outlet of the second stage of compression. The at least one location can be between an outlet of the air-cooled heat exchanger and an inlet of the control valve. Manipulating the control valve can include modulating the control valve.

[0009]In one embodiment, the control valve can include a first inlet which is coupled to an outlet of the first stage of compression, the control valve can in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com