Paperboard CD or DVD tray with paper hub

a technology of paper hub and cd tray, which is applied in the direction of packaging goods, instruments, transportation and packaging, etc., can solve the problems of plastic cd tray breakage and inability to be durable, and achieve the effect of improving durability, reducing manufacturing costs, and duplicated plastic cd tray functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]Reference will now be made in greater detail to a preferred embodiment of the invention, an example of which is illustrated in the accompanying drawings. Wherever possible, the same reference numerals will be used throughout the drawings and the description to refer to the same or like parts.

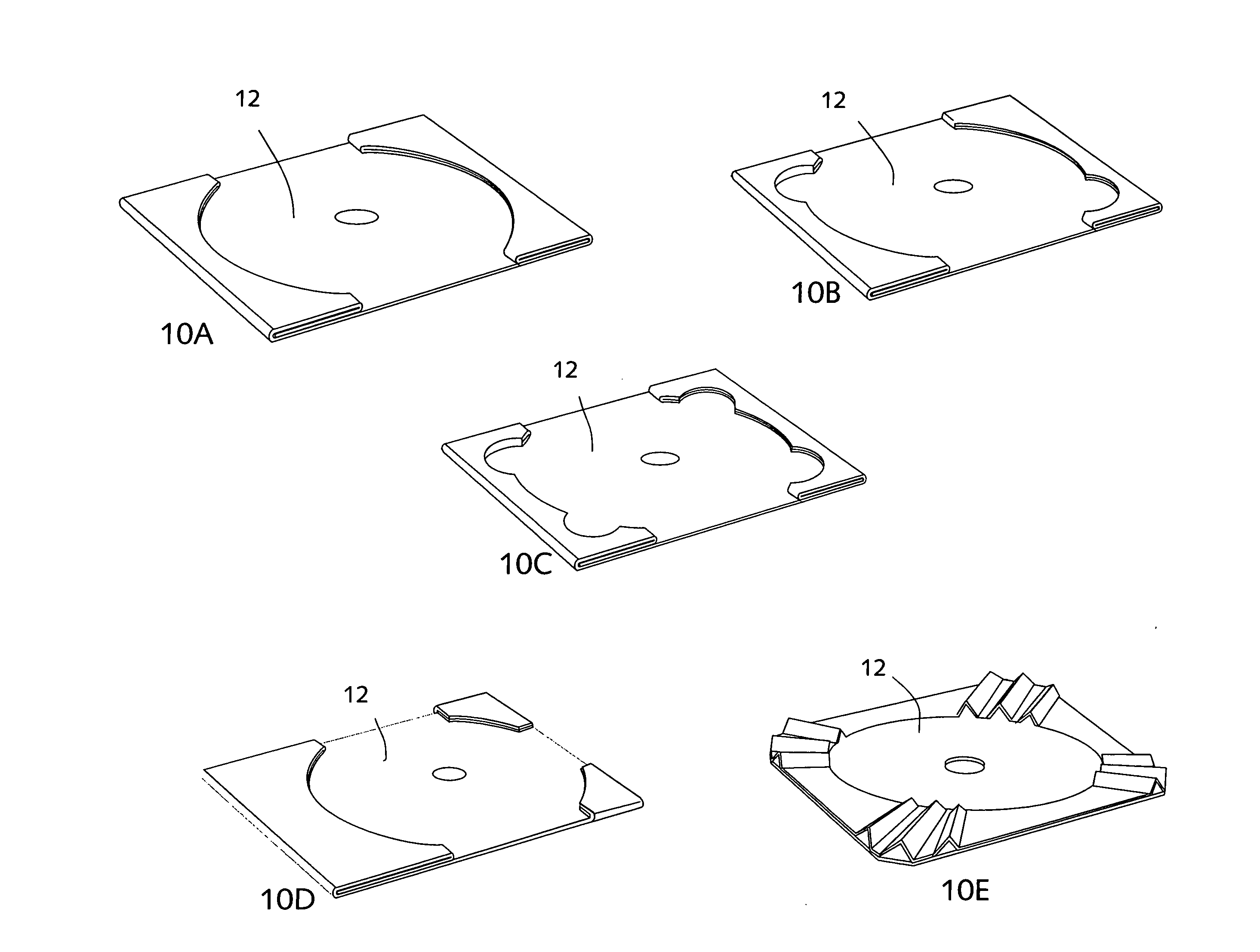

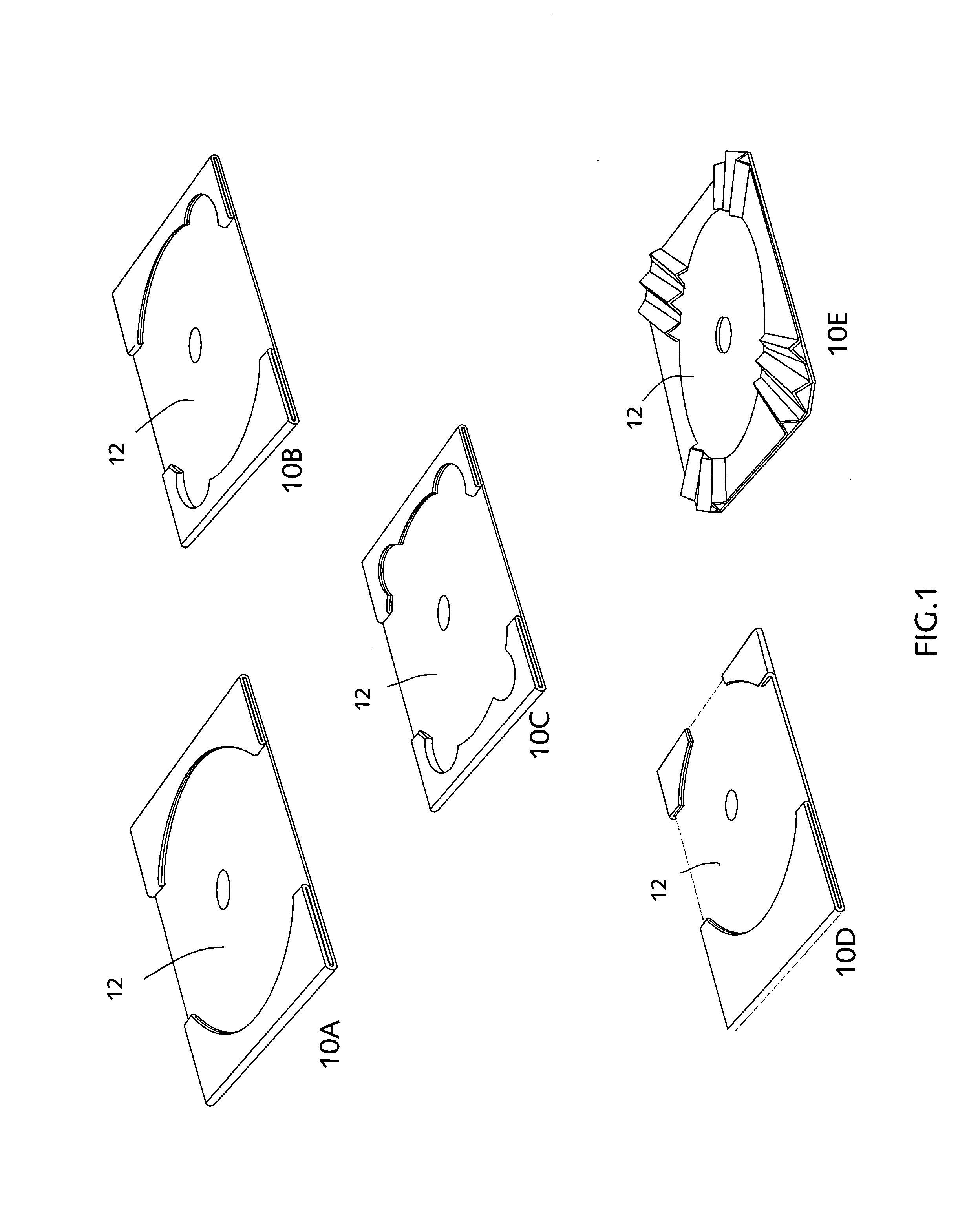

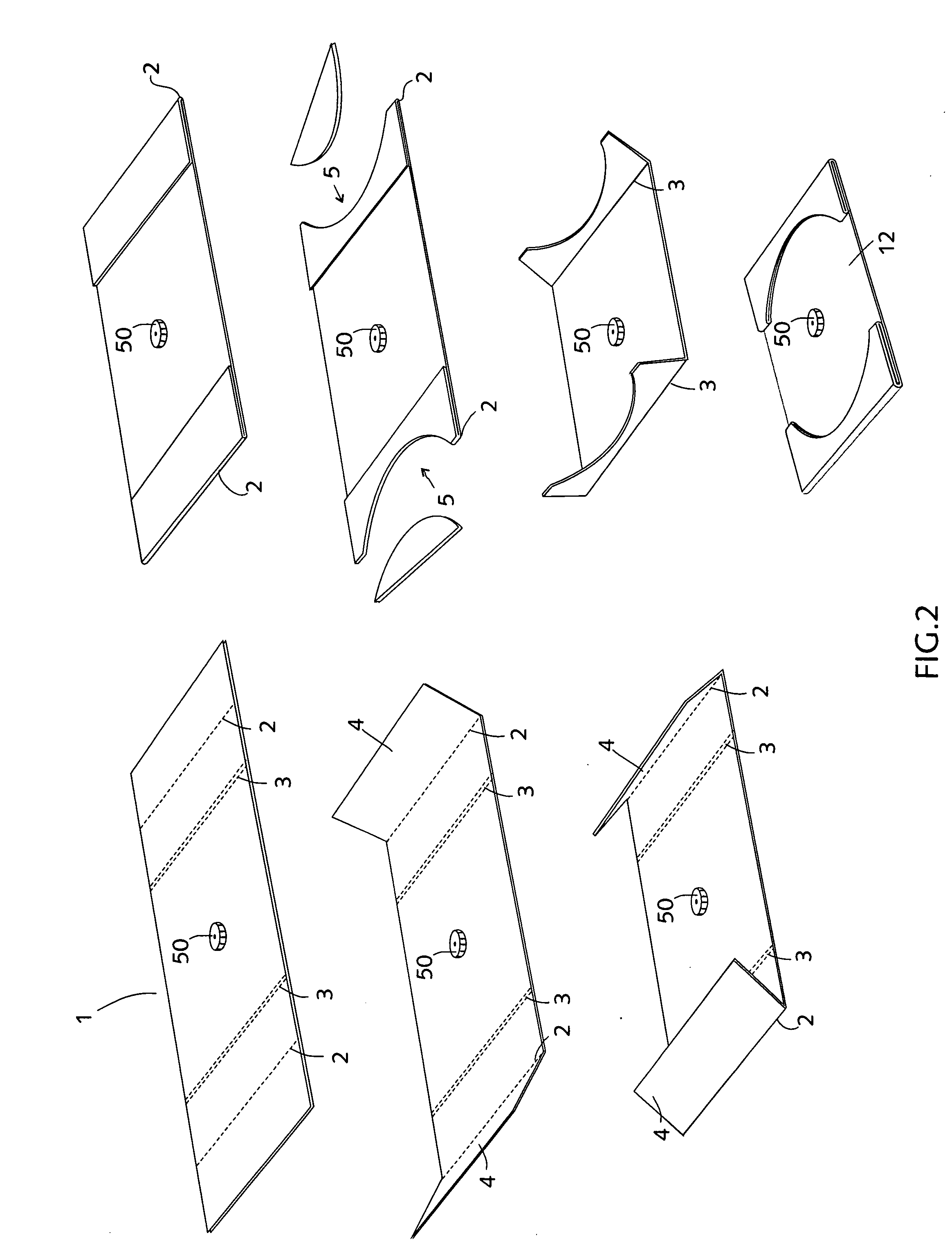

[0036]A preferred embodiment has two components: a tray 10 and a post 50 (or interchangeably referred to as a hub). The hub 50 protrudes from the surface of the tray 10 on the side of the tray 10 that will secure the disc (not shown) CD, DVD or other similar flat circular object with a circular aperture in the approximate center of the object (hereinafter reference to a CD or disc includes CDs, DVDs, digital CDs and any other flat circular object that is to be secured by the tray). The hub 50 can be integral with the tray 10, or alternatively, the hub 50 can be a separate component that is attached or adhered to the tray 10. The tray serves to protect the CD from being scratched or damaged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com