Gravity compensation device

A technology of gravity compensation and air chamber, which is applied in the direction of photolithography exposure device, microlithography exposure equipment, spring/shock absorber, etc., can solve the problems of rigid spring static position deviation, increased use cost, high cost, etc., to achieve Effects of reducing resonance, eliminating errors, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

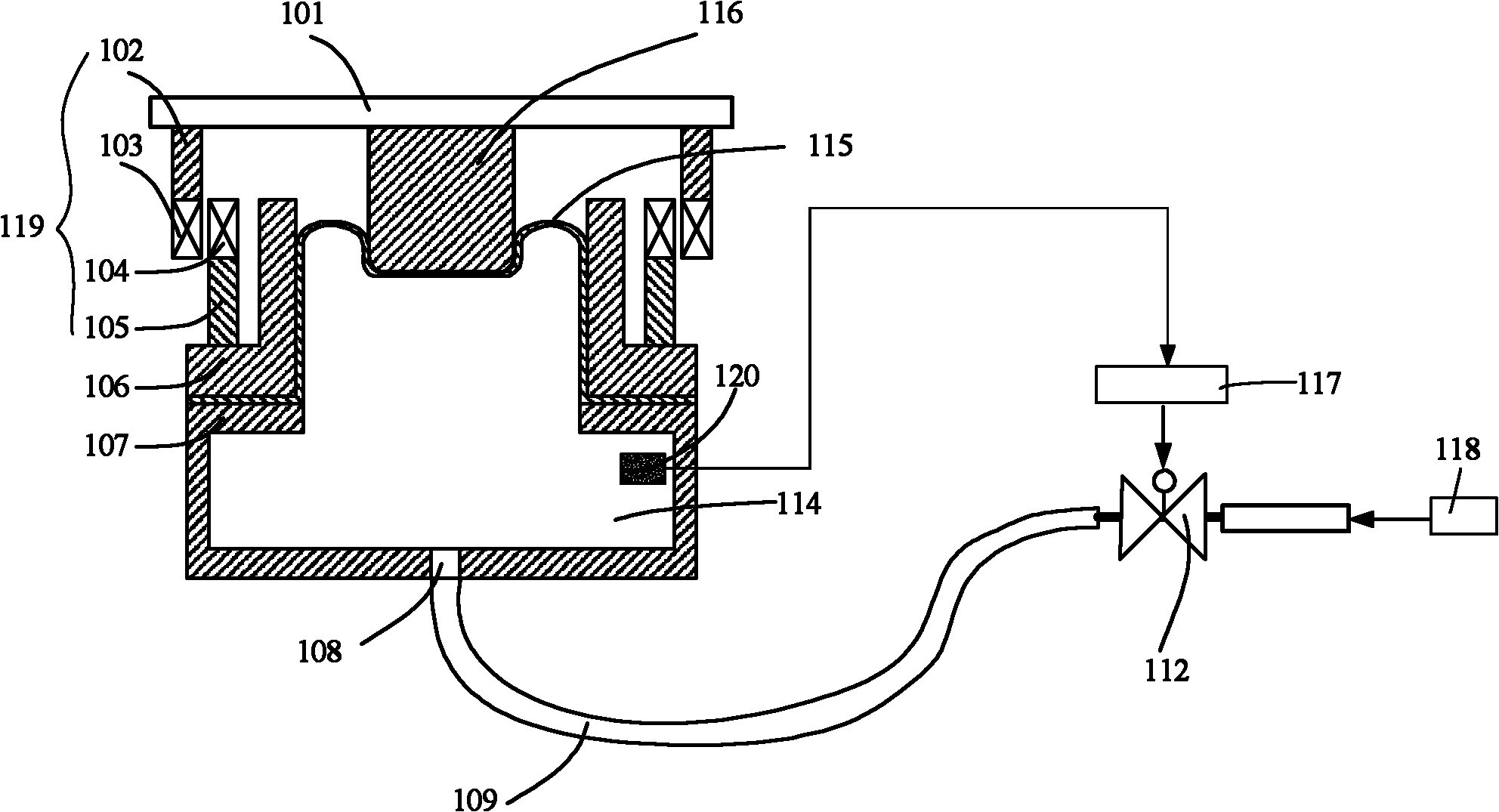

[0027] figure 1 It is a schematic structural diagram of the gravity compensation device in an embodiment of the present invention, please refer to figure 1 In combination with the above core idea, the present invention provides a gravity compensation device, which communicates with the air supply source 118 and includes the first air chamber shell 107, the bushing 106, the membrane structure 115, the piston 116, the support plate 101 and the pneumatic valve 112, wherein the bushing 106 is located above the first air chamber housing 107; the two ends of the membrane structure 115 are between the bushing 106 and the first air chamber housing 107, so that the membrane structure 115 and the first air chamber shell 107 form the first air chamber 114; the piston 116 is supported on the membrane structure 115; the support plate 101 is fixed above the piston 116; the pneumatic valve One end of 112 communicates with the gas path of the first air chamber 114 , and the other end communi...

specific Embodiment 2

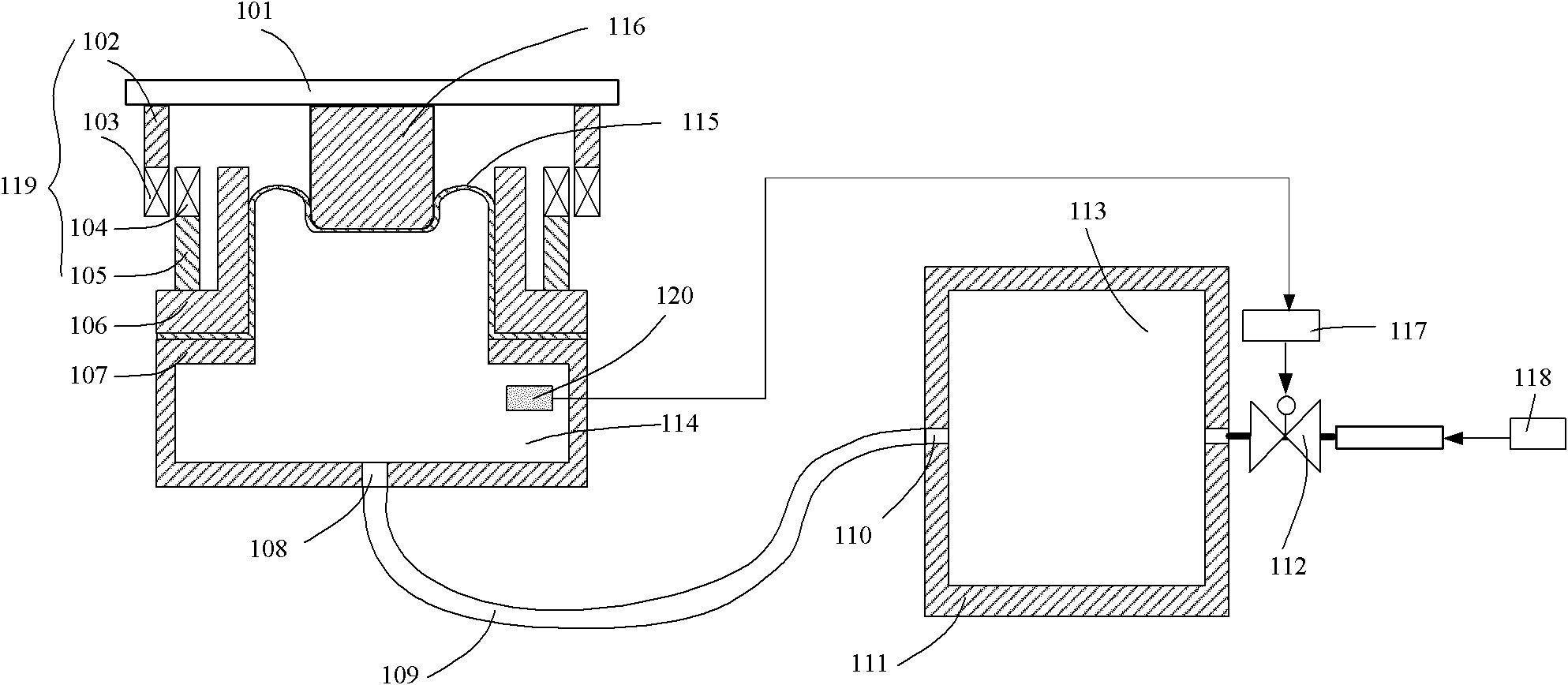

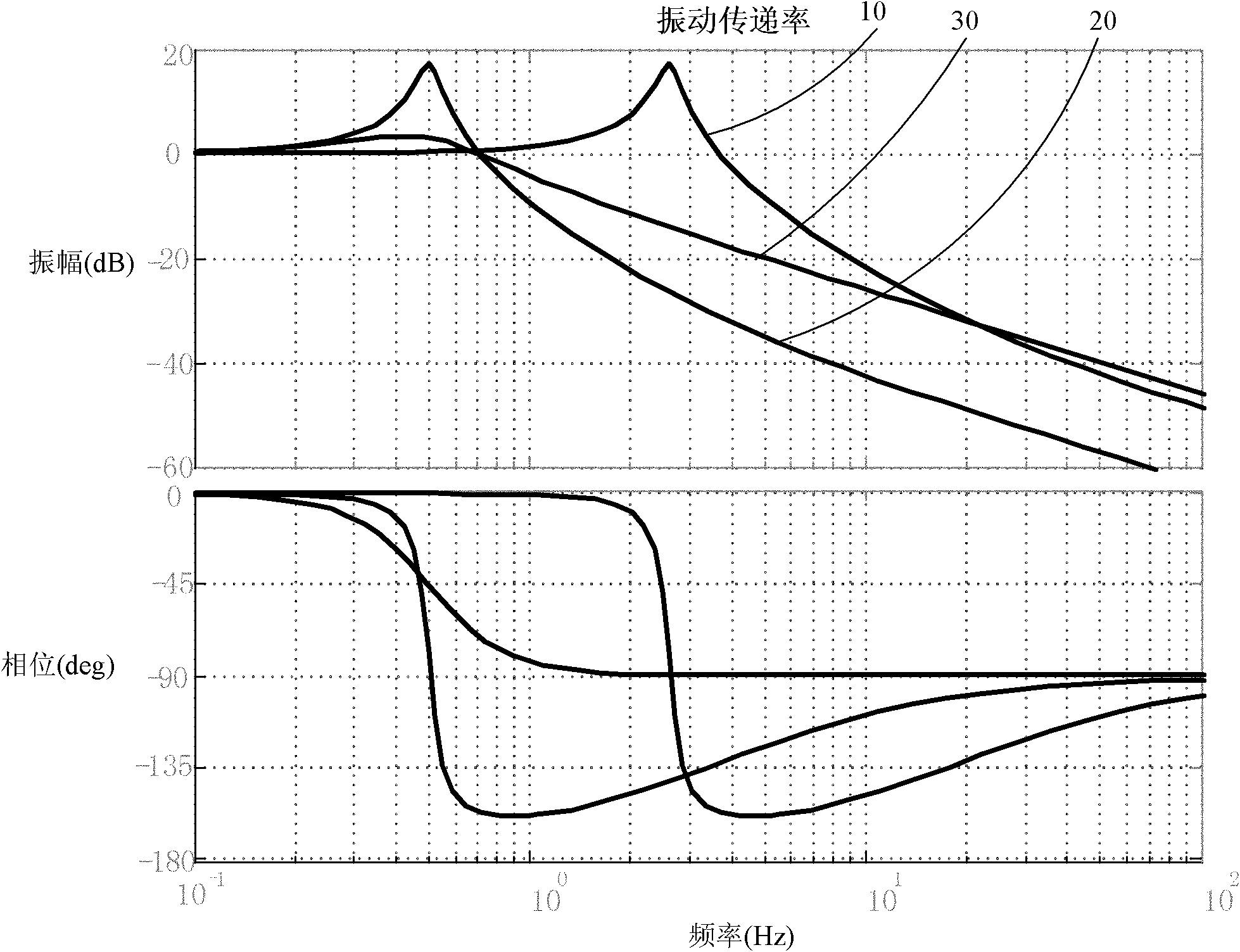

[0052] figure 2 It is a structural schematic diagram of the gravity compensation device in another embodiment of the present invention, please refer to figure 2 . On the basis of the first embodiment, a second air chamber 113 is added between the first air chamber 114 and the pneumatic valve 112 . The second air chamber 113 is sealed inside the second air chamber housing 111, and a second air chamber aperture 110 is arranged on the second air chamber housing 113, and the second air chamber aperture 110 is connected to the second air chamber housing 111. The first air chamber 114 communicates with the air path, and the second air chamber small hole 110 communicates with the first air chamber small hole 108 through a trachea. Preferably, the small hole in the second air chamber is a damping hole. The damping hole is designed so that the damping rate of the gravity compensation device is between 0.01 and 0.85, wherein preferably, the damping rate is 0.4-0.7. Within the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com