Binder for coke powder molding and application method thereof

A binder and coke powder technology, applied in the petroleum industry, solid fuel, fuel, etc., can solve the problems of high price, low thermal stability, environmental pollution, etc., and achieve the effect of simple application method and reasonable formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

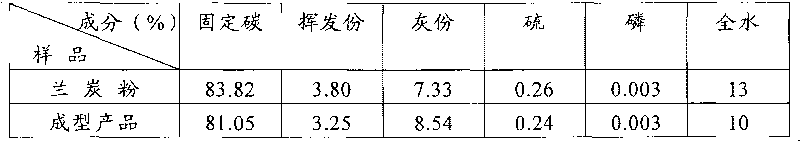

Image

Examples

Embodiment 1

[0029] Weigh the following substances in parts by weight (unit: kg)

[0030] Binder:

[0031] Component A: 5.3 parts, including 2 parts of vegetable protein glue, 3 parts of wollastonite, 0.3 parts of boric acid,

[0032] Component B: 0.2 parts of γ-aminopropyltriethoxysilane,

[0033] Coke powder (particle size <3mm): 100 parts,

[0034] Water: 10 parts;

[0035] Dissolve component B of binder in 1 / 3 of the weighed water to obtain solution 1; evenly spray solution 1 on the coke powder in a stirring state to obtain mixture 1; add component A of binder In the mixture 2, use a strong agitator (ordinary vertical mortar mixer or horizontal screw strong mixer conveyor) to fully stir, then spray the remaining 2 / 3 of the water, and continue stirring until it is completely homogenized to obtain the mixture 2 ; The mixture 2 is made into pellets (blocks) with a molding machine, and after molding, it is dried at 150°C for 30 minutes, and the average strength of the finished product ...

Embodiment 2

[0037] Weigh the following substances in parts by weight (unit: kg)

[0038] Binder:

[0039] Component A: 7.85 parts, including 2.5 parts of hydroxyethyl starch, 0.35 parts of boric acid, and 5 parts of bentonite;

[0040] Component B: 0.1 parts of γ-aminopropyltrimethoxysilane;

[0041] Coke powder (particle size <3mm): 100 parts;

[0042] Water: 10 parts;

[0043] Dissolve component B of binder in 1 / 3 of the weighed water to obtain solution 1; evenly spray solution 1 on the coke powder in a stirring state to obtain mixture 1; add component A of binder In the mixture 2, use a strong agitator (ordinary vertical mortar mixer or horizontal screw strong mixer conveyor) to fully stir, then spray the remaining 2 / 3 of the water, and continue stirring until it is completely homogenized to obtain the mixture 2 ; The mixture 2 is made into pellets (blocks) with a molding machine, dried at 150°C for 20 minutes after molding, and the average strength of the finished product is 1050N...

Embodiment 3

[0045] Weigh the following substances in parts by weight (unit: kg)

[0046] Binder:

[0047] Component A: 5.7 parts, including 2 parts of carboxymethyl cellulose ether, 0.2 parts of borax, and 3.5 parts of kaolin;

[0048] Component B: 0.3 parts of γ-aminopropyltrimethoxysilane;

[0049] Coke powder (particle size <3mm): 100 parts;

[0050] Water: 15 parts;

[0051] Dissolve component B of binder in 1 / 3 of the weighed water to obtain solution 1; evenly spray solution 1 on the coke powder in a stirring state to obtain mixture 1; add component A of binder In the mixture 2, use a strong agitator (ordinary vertical mortar mixer or horizontal screw strong mixer conveyor) to fully stir, then spray the remaining 2 / 3 of the water, and continue stirring until it is completely homogenized to obtain the mixture 2 ; The mixture 2 is made into pellets (blocks) with a molding machine, dried at 200°C for 30 minutes after molding, and the average strength of the finished product is 1080N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com