Catalyst without mercury for hydrochlorination of acetylene as well as preparation method and use thereof

A technology of acetylene hydrochlorination and mercury catalyst, applied in the direction of physical/chemical process catalysts, hydrogen halide addition preparation, chemical instruments and methods, etc., can solve the problems of highly toxic catalysts, achieve high utilization efficiency and increase production efficiency , the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

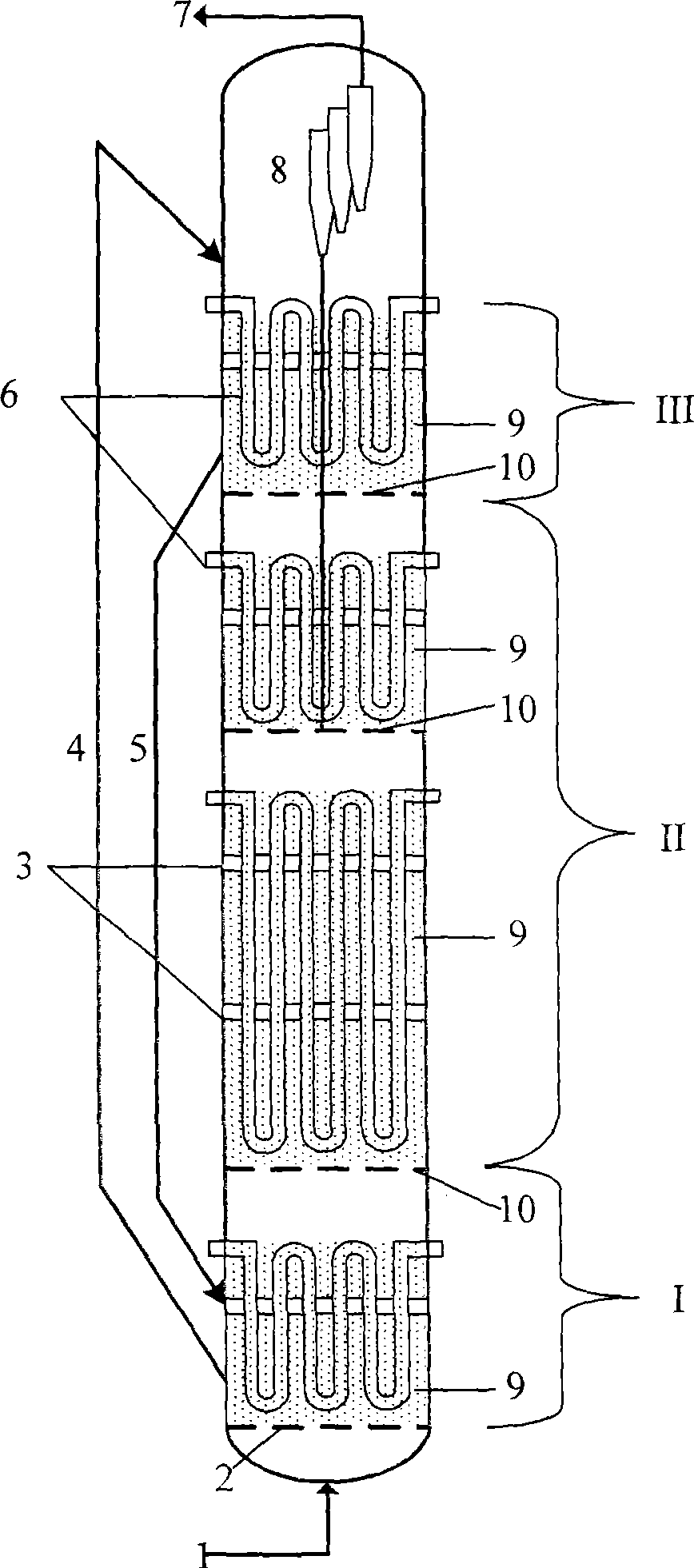

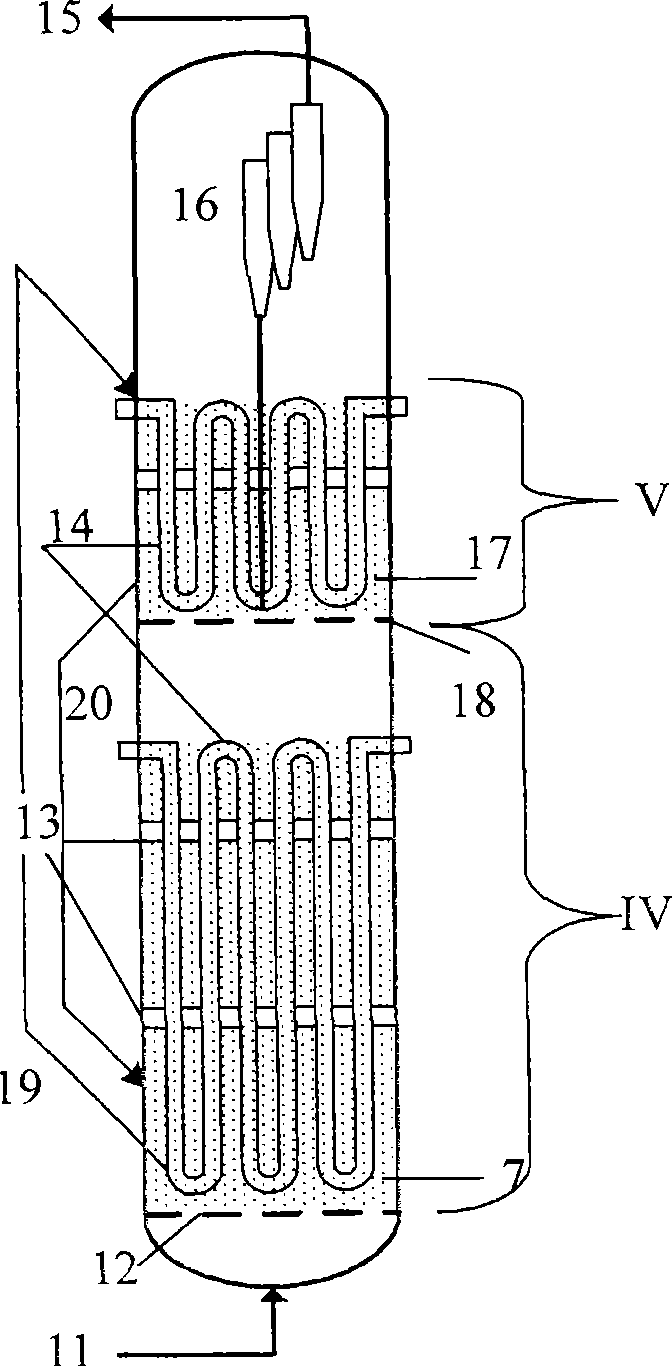

Method used

Image

Examples

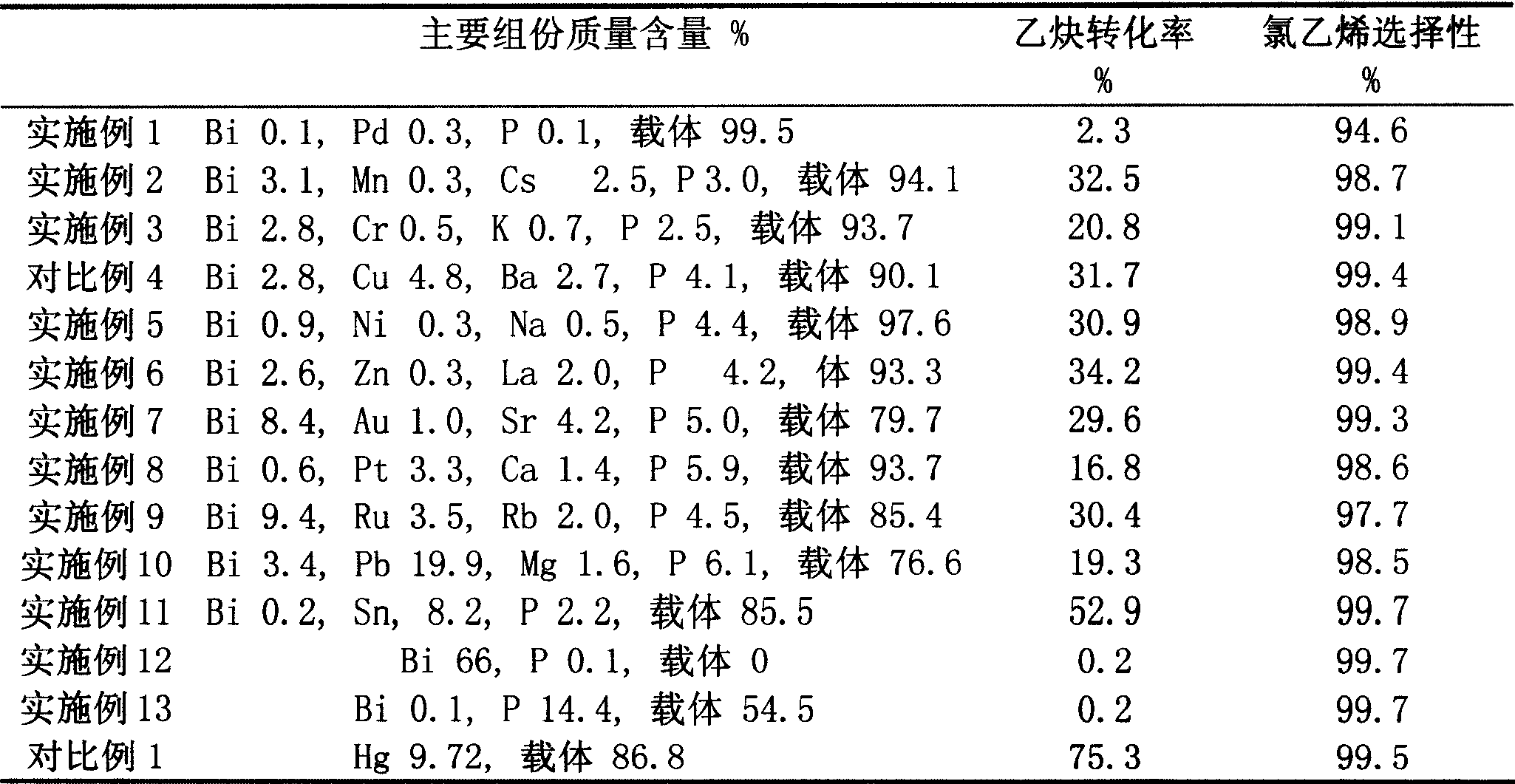

Embodiment 1

[0060] Dissolve 0.01g of bismuth chloride and 0.04g of palladium chloride in 10g of 0.1% hydrochloric acid and 0.2% phosphoric acid aqueous solution, and stir evenly until all the solids are dissolved. The specific surface area of 6g is 350-400m 2 / g, 100-200 mesh SiO 2 Add it into the prepared solution, let it stand for 5 hours, dry it at 120°C for 5 hours, and then bake it at 450°C for 8 hours.

Embodiment 2

[0062] Dissolve 0.3g of bismuth chloride, 0.05g of manganese chloride and 0.2g of cesium chloride in 10g of 3% hydrochloric acid and 6% phosphoric acid aqueous solution, and stir evenly until all the solids are dissolved. The specific surface area of 6g is 350-400m 2 / g, 100-200 mesh SiO 2 Add it into the prepared solution, let it stand for 5 hours, dry it at 120°C for 5 hours, and then bake it at 400°C for 8 hours.

Embodiment 3

[0064] Dissolve 0.3g of bismuth phosphate, 0.2g of chromium chloride hexahydrate, and 0.1g of potassium chloride in 10g of 3% hydrochloric acid and 6% phosphoric acid aqueous solution, and stir evenly until all the solids are dissolved. The specific surface area of 7g is 150-200m 2 / g, 100~200 mesh α-Al 2 o 3 Add it into the prepared solution, let it stand for 5 hours, dry it at 120°C for 5 hours, and then bake it at 800°C for 8 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com