Gas transformation deep purifying technique for separating and purifying CO and H2 of calcium carbide furnace

A deep purification, calcium carbide furnace gas technology, applied in the chemical industry, inorganic chemistry, climate sustainability, etc., can solve the problems of low concentration sulfur removal, single sulfur content, difficulty, etc., to achieve stable operation of the device , High heat utilization rate, and the effect of inhibiting methanation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

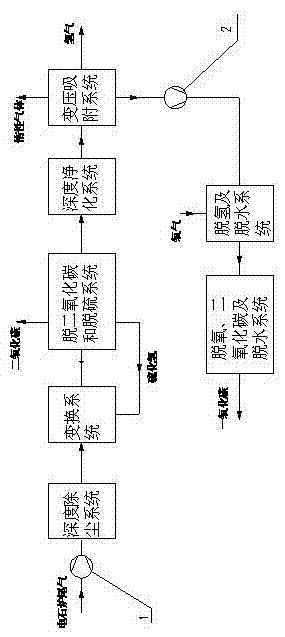

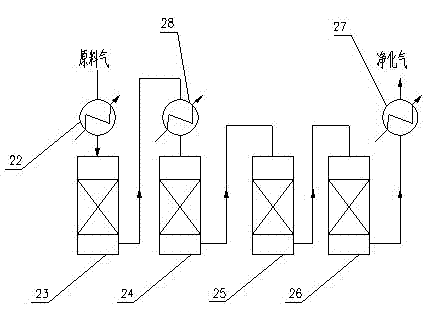

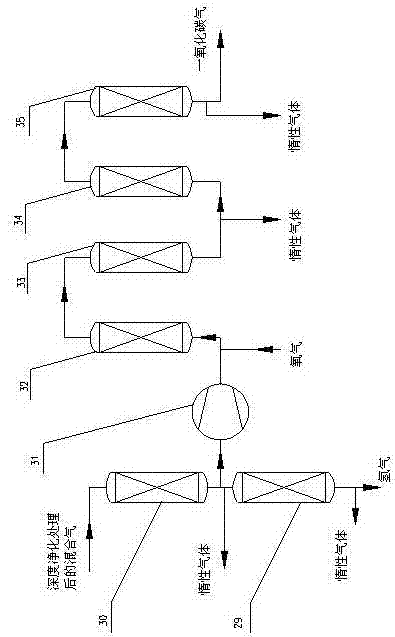

[0041] Refer to attached Figure 1-5 , this embodiment includes the following steps:

[0042] ①Boosting: The tail gas of the calcium carbide furnace first enters the compressor I1 to increase the pressure to ensure the use of the subsequent process;

[0043] ②Deep dust removal system: Send the exhaust gas of the calcium carbide furnace after the pressure is raised to the wet dust collector for dust removal;

[0044] ③ Transformation system: Send the dust-removed calcium carbide furnace tail gas into the transformation system, and use low water-gas ratio and low-temperature transformation technology under the action of catalyst A to convert part of carbon monoxide into carbon dioxide and hydrogen;

[0045] ④Decarbonation and desulfurization system: send the mixed gas treated by the conversion system into the decarbonation and desulfurization system, separate the carbon dioxide and sulfur-containing components in the mixed gas, and release carbon dioxide and hydrogen sulfide ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com