Non-woven fabric tissue containing detergent and method for manufacturing same

A manufacturing method and technology of non-woven fabrics, applied in textiles and papermaking, non-woven fabrics, thorn patterns, etc., can solve the problems of reducing shrinkage and reducing the grip of non-woven fabrics, increasing voids, reducing oil content and discharging sewage, The effect of high oil absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

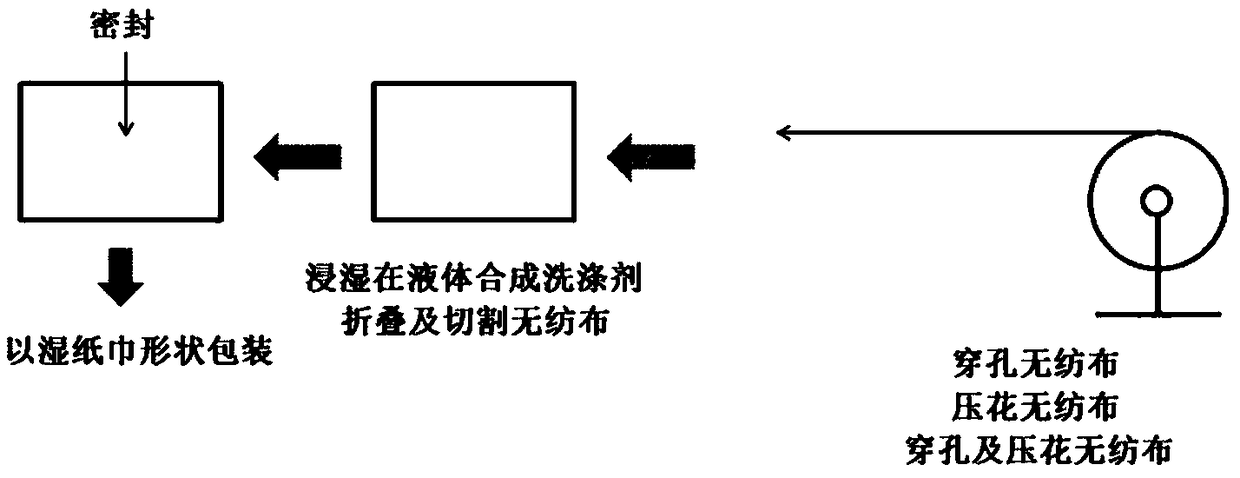

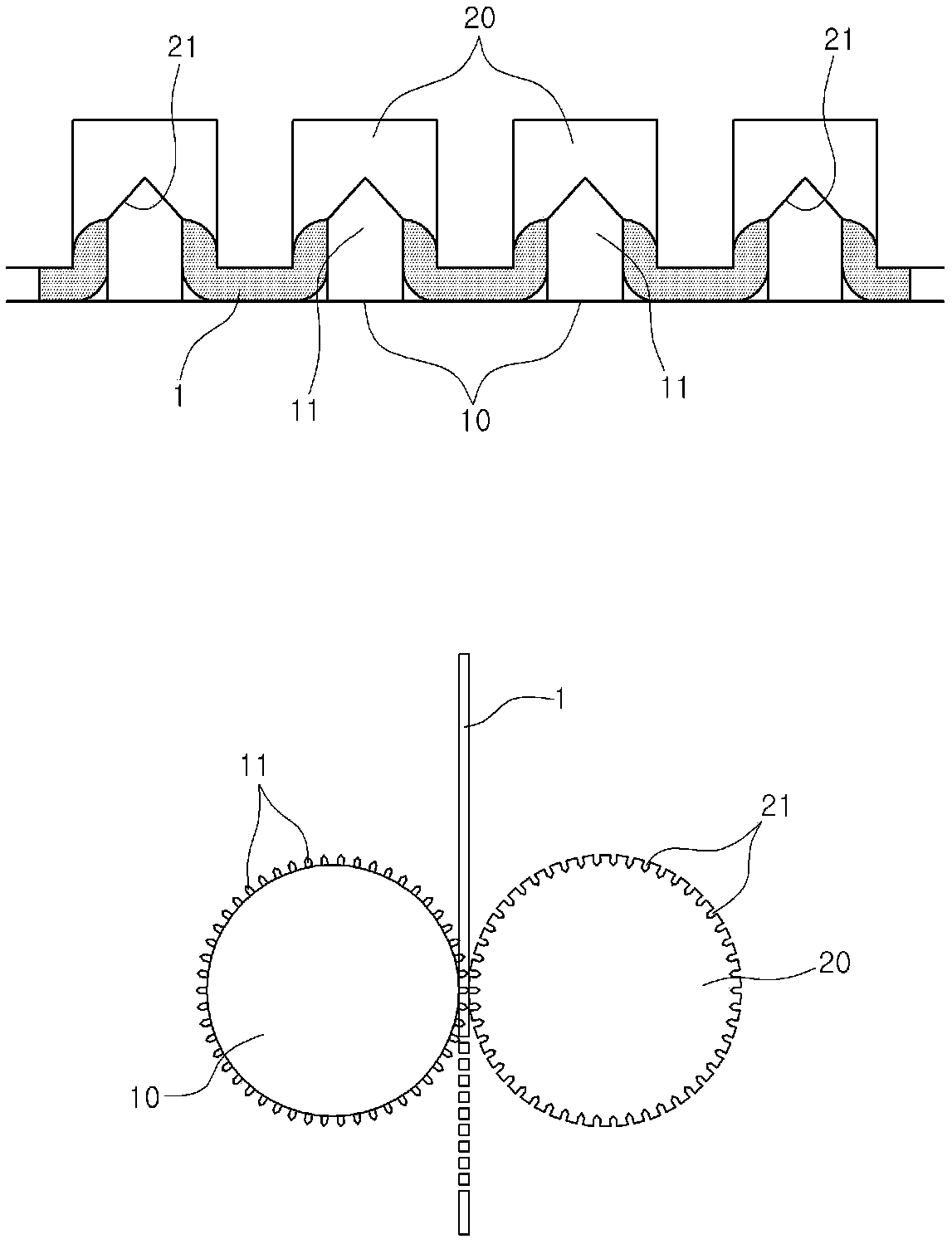

[0113] Preparation of 38 g / m by punching with a punch with a double gap of 2 mm and a length of the main part of the pin of 1.9 mm 2 polypropylene spunbond nonwoven fabric. A kitchen detergent solution was prepared by mixing 40 parts by weight of a commercially available kitchen detergent (12% surfactant), 8 parts by weight of sodium lauryl ether sulfate and 52 parts by weight of water per 100 parts by weight of the kitchen detergent solution .

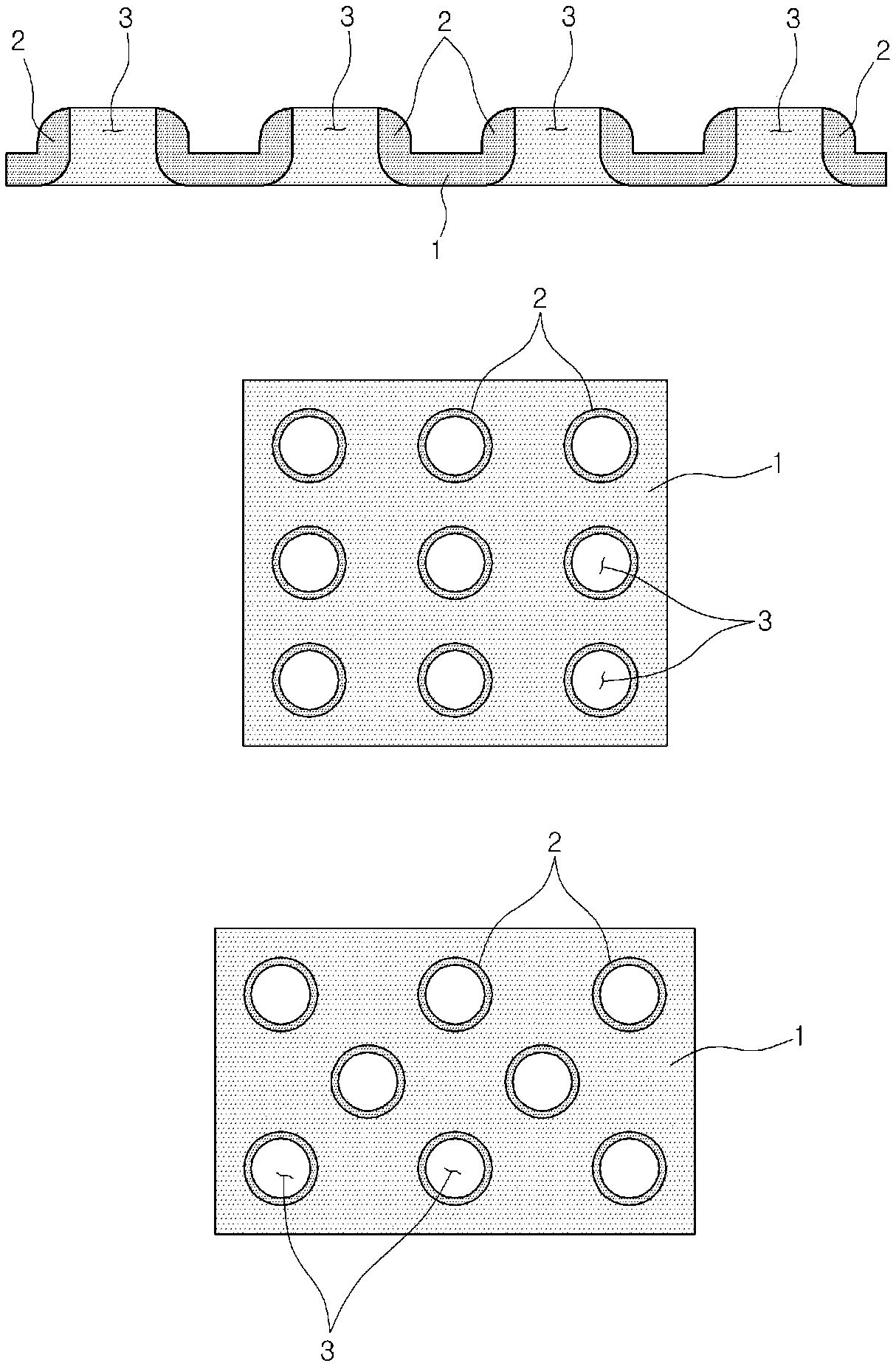

[0114] When the non-woven fabric is unfolded, such as Figure 11 As shown, a non-woven fabric with a width of 21cm and a length of 28cm is folded into 10cm and 14cm in length, 40 pieces of cut non-woven fabrics are stacked and packed in a packaging bag, and 350g of diluted kitchen detergent liquid is poured Put it into the packaging bag for adsorption, and then seal the packaging bag, such as Figure 10 As shown, a non-woven paper towel adsorbed with a synthetic detergent solution was made.

Embodiment 2

[0116] In addition to using 40g / m with embossed surface 2 Except the polypropylene spun-bonded non-woven fabric, non-woven paper towels were produced with the same composition, content, size and method as in Example 1.

Embodiment 3

[0118] In addition to using 40g / m2 with 100% polypropylene yarn 2 Except the heat-bonded non-woven paper towels of the above, the non-woven paper towels were manufactured with the same composition, content, size and method as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com