Biodegradable phosphorus-free detergent additive and preparation method thereof

A technology of detergent builder and biodegradation, applied in detergent composition, non-surface active detergent composition, organic detergent composition, etc., can solve the problems of poor chelation and dispersion ability, and achieve the increase of side chain charge density Large size, simple preparation method, and the effect of being convenient for industrialized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

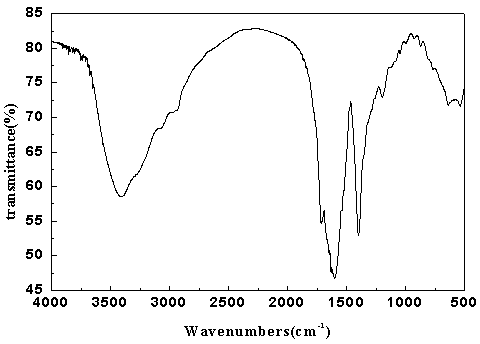

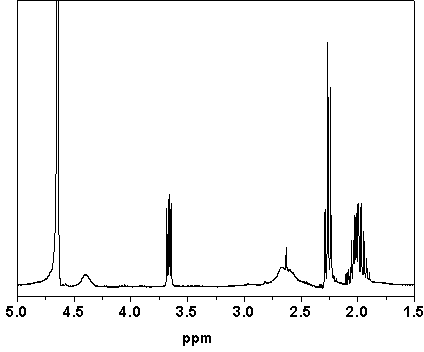

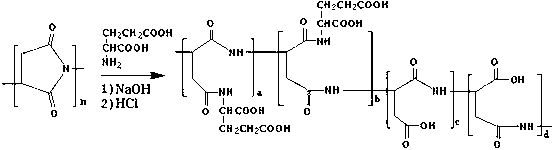

Embodiment 1

[0047]Add 9.8g of maleic anhydride and 10mL of distilled water into the three-necked flask, raise the temperature and stir to dissolve, and add dropwise 10mL of aqueous solution containing 3.0g of urea to 60°C. After the dropwise addition, a colorless solution is obtained. After 1 hour, a clear solution was obtained; the clear solution prepared above was distilled under reduced pressure at 130°C to obtain white crystals and a small amount of viscous mixture, which was then heated to 180°C. Under reduced pressure, the condensation reaction was carried out for 0.5 hours to obtain orange, The brittle solid is polysuccinimide; 1.47g of glutamic acid is dissolved with 6.5mL of 2mol / L sodium hydroxide solution to obtain a sodium glutamate solution; Add 4.85g polysuccinimide to the three-necked flask, then add 15mL water to suspend it in water, slowly add sodium glutamate solution dropwise under stirring, and adjust the pH to 8 with 2mol / L sodium hydroxide solution, and react The tem...

Embodiment 2

[0049] Add 10.0g of maleic anhydride and 12mL of distilled water into the three-necked flask, raise the temperature and stir to dissolve, and then add dropwise 10mL of aqueous solution containing 3.6g of urea to 70°C. After the dropwise addition, a colorless solution is obtained. After 1 hour, a clear solution was obtained; the clear solution prepared above was distilled under reduced pressure at 120°C to obtain white crystals and a small amount of viscous mixture, and continued to heat up to 160°C. Under reduced pressure, the condensation reaction was carried out for 1.0 hour to obtain orange , brittle solid, which is polysuccinimide; 4.41g of glutamic acid is dissolved with 16.5mL of 2mol / L sodium hydroxide solution to obtain sodium glutamate solution; Add 4.85g of polysuccinimide to a three-necked flask, then add 15mL of water to suspend it in water, slowly add sodium glutamate solution dropwise under stirring, and adjust the pH to 8 with 2mol / L sodium hydroxide solution, T...

Embodiment 3

[0051] Add 9.8g of maleic anhydride and 12mL of distilled water into the three-necked flask, raise the temperature and stir to dissolve, and then add dropwise 10mL of aqueous solution containing 4.2g of urea to 80°C. After the dropwise addition, a colorless solution is obtained. hours, a clear solution was obtained; the clear solution prepared above was distilled under reduced pressure at 110°C to obtain white crystals and a small amount of viscous mixture, and the temperature was continued to 200°C. Under reduced pressure, the condensation reaction was carried out for 1.0 hour to obtain an orange , brittle solid, which is polysuccinimide; 7.35g of glutamic acid is dissolved with 37.5mL of 2mol / L sodium hydroxide solution to obtain sodium glutamate solution; Add 4.85g of polysuccinimide to a three-necked flask, then add 15mL of water to suspend it in water, slowly add sodium glutamate solution dropwise under stirring, and adjust the pH to 9 with 2mol / L sodium hydroxide solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com