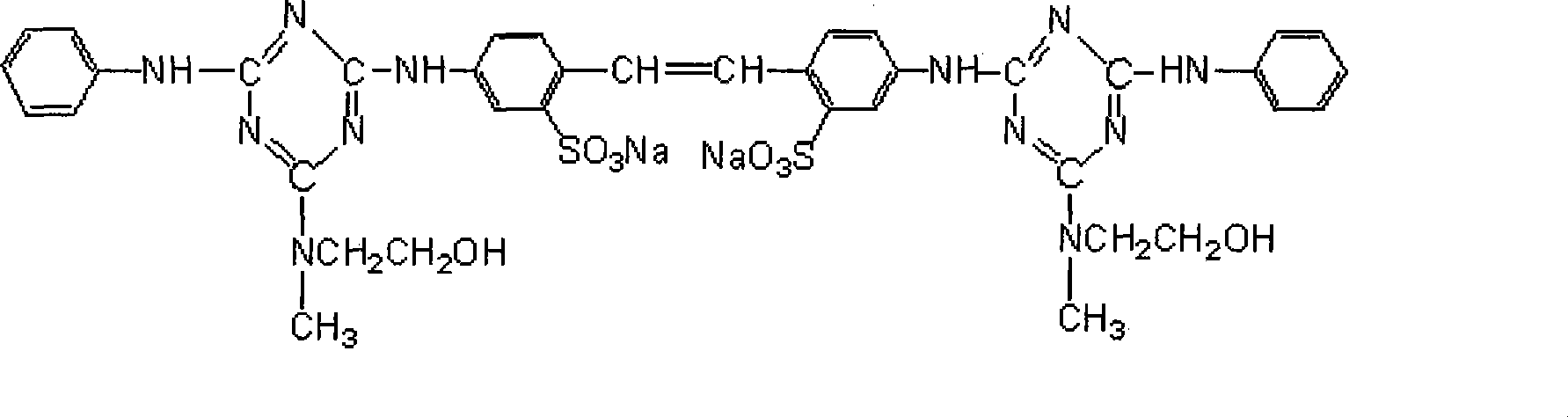

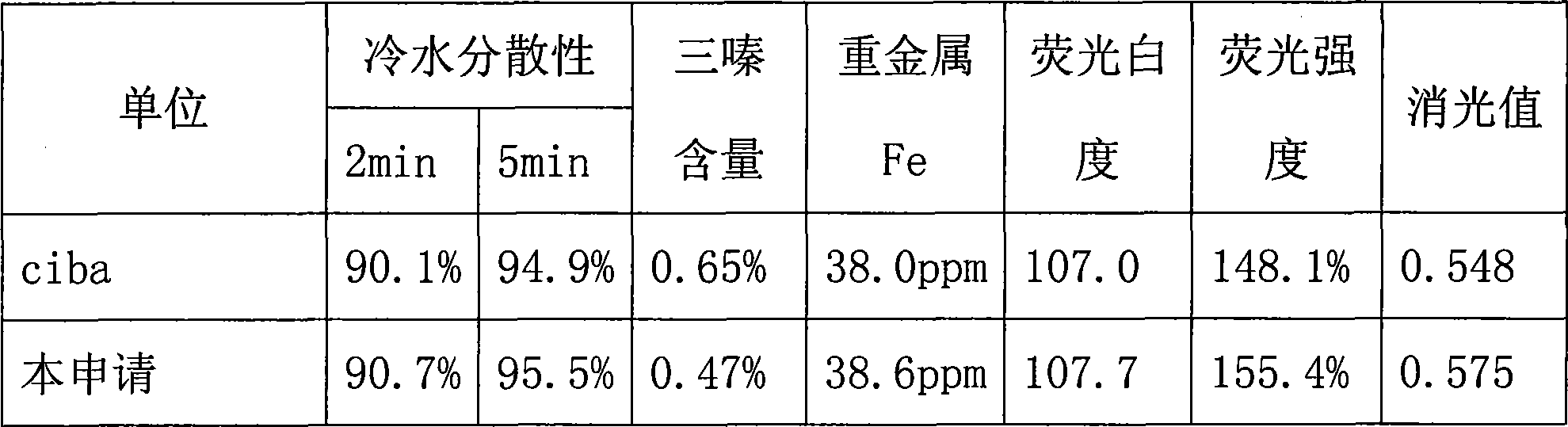

Process for producing fluorescent whitening agent 5BM

A fluorescent whitening agent and ice water technology, applied in chemical instruments and methods, luminescent materials, styrene-based dyes, etc., can solve the problems of low product quality, and achieve the effects of simple preparation methods, avoiding dust pollution, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: the preparation method of a kind of fluorescent whitening agent 5BM, the steps are: according to the ratio of molar ratio 2:1, get cyanuric chloride and DSD acid and put into reactor, add appropriate amount of ice water (consumption according to every 200 -250 kg of DSD acid is added corresponding to the amount of 2000-2200 liters of ice water, cyanuric chloride is insoluble in water, the purpose is ice grinding), adjust the pH value to 1-1.5, and then add sodium carbonate to neutralize the reaction generated Hydrochloric acid, adjust the pH value to 6-6.5, after the amino value of DSD acid disappears, add aniline with a molar ratio of 2, and add 2 moles of N-methylethanolamine after the aniline disappears, and make the pH value 10-12 by adding NaOH , and then cooled to 5°C with ice water to precipitate the product, then filtered, dried, and pulverized to obtain the 5BM product.

Embodiment 2

[0016] Embodiment 2: solvent method is made granular 5BM product (contrast):

[0017] Add 375g of crushed ice and 300g of butanone into a 2000mL flask equipped with stirring, pH meter, thermometer, reflux condenser and dropping funnel, mix well and cool down to -7°C. Then add 50g of cyanuric chloride, add 50g of DSD acid under vigorous stirring, (full name 4,4'-diaminostilbene-disulfonic acid) keep the temperature ≤ 5°C under ice bath for 30-40 minutes 195mL15% sodium carbonate solution was added dropwise, so that the pH value of the reaction solution was maintained at 3-4 at first, and then to 5-6. After the disappearance of the DSD acid, an easy-to-stirrable tan-yellow homogeneous slurry was obtained. Then the temperature was raised to 20°C, and 25.2g of aniline was added dropwise within 5 minutes, and at the same time, 22g of 50% NaOH solution was added dropwise at 27-30°C, so that the pH value of the reaction solution was maintained at 4-5 at first, and then to 8.0-8.5. ...

Embodiment 3

[0018] Embodiment 3: take the present invention as example non-solvent method to manufacture granular 5BM product

[0019] Add 100g of crushed ice and 100g of water into a 2000mL beaker, stir evenly, add 10% hydrochloric acid to adjust the pH to 1-1.5, add 10g of cyanuric chloride for beating for 0.5 hours, then add 9.75g of DSD acid (solution Concentration in the range of 100-120g / L), while maintaining 5°C, add 2.78g (0.026mol) 10% sodium carbonate solution dropwise in 30-40 minutes to keep the pH at 5-5.5, Then adjust it to 6-6.5. After the amino value disappears, add 5.2g of aniline, and at the same time add 2.95g (0.028mol) of 10% sodium carbonate solution dropwise at 20-35°C to keep the pH between 7-7.5. After disappearing, add 4.8g of N-methyl monoethanolamine at one time, and heat it to 80°C, keep it warm for 1.5 hours, the pH value of the reaction solution is 10 at first, and then drops rapidly,

[0020] 2.2 g (0.055 mol) of 20% NaOH solution was added dropwise to mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com