Patents

Literature

34 results about "N-Methylethanolamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

N-Methylethanolamine is an alkanolamine with the formula CH₃NHCH₂CH₂OH. It is flammable, corrosive, colorless, viscous liquid. It is an intermediate in the biosynthesis of choline. With both an amine and a hydroxyl functional groups, it is a useful intermediate in the chemical synthesis of various products including polymers and pharmaceuticals. It is also used as a solvent, for example in the processing of natural gas, where it is used together with its analogs ethanolamine and dimethylethanolamine.

Moisture-permeable waterproof film used for fabric and fabrication process thereof

ActiveCN102555380ASolve the weakness that it is easy to expand when exposed to waterGood moisture permeabilitySynthetic resin layered productsLaminationSlurryMoisture

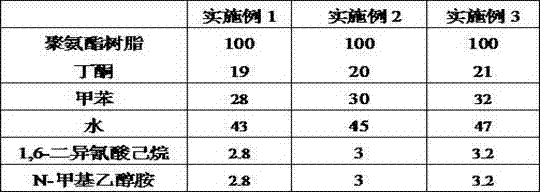

The invention discloses a moisture-permeable waterproof film used for a fabric and a fabrication process thereof. According to the invention, a primary coating comprises polyurethane resin, butanone, toluene, water, hexane diisocyanate and N-methylethanolamine, and a first and second surface coatings comprise polyurethane resin, butanone, toluene, water and N-methylethanolamine. The fabrication process comprises the following steps: mixing hexane diisocyanate with main resin; mixing water with butanone to form a solvent which is put into a main resin mixed solution in at least six steps; filtering the mixed solution with a nylon net so as to obtain a filtered main resin mixed solution and carrying out deaeration treatment so as to form a primary coating slurry; preparing a surface coating slurry with the viscosity of a conjugate solution being 3500 to 6000 mpas; coating the primary coating slurry on the surface of release paper to form the primary coating, with coated weight being 4 to 6 g / m<2>; coating the surface coating slurry on the surface of the primary coat to form the surface coatings; and drying the release paper with the surface coatings and peeling the surface coatings off the release paper. According to the invention, the disadvantages that existing hydrophilic moisture permeable processing coating fabrics have nonuniform micropores and easily swell when contacting with water are overcome, and therefore, moisture permeable performance of a fabric itself is improved.

Owner:KUNSHAN HUAYANG NEW MATERIAL

Moisture permeation and water proofing fabric, and preparation process thereof

InactiveCN102619092ASolve the weakness that it is easy to expand when exposed to waterGood moisture permeabilityFibre treatmentCoated surfaceMoisture permeation

The present invention discloses a moisture permeation and water proofing fabric, and a preparation process thereof. According to the fabric, a prime coat comprises: a polyurethane resin, butanone, toluene, water, 1,6-diisocyanatohexane and N-methylethanolamine; a first surface coating and a second surface coating comprise a polyurethane resin, butanone, toluene, water and N-methylethanolamine. The preparation process comprises: mixing 1,6-diisocyanatohexane and a main resin; mixing water and butanone to form a solvent; adding the solvent to the main resin mixing solution in at least 6 times; filtering the resulting mixed solution with a nylon net to obtain a filtered main resin solution; carrying out a deaeration treatment to form a prime coat slurry; blending a surface coating slurry with a matching solution viscosity of 3500-6000 mpas; coating the prime coat slurry on the surface of the base cloth to form the prime coat, and drying; coating the surface coating slurry on the surface of the prime coat in 2 times to form the surface coatings, and drying. In the prior art, micropores in the hydrophilic moisture permeation processing coating fabric are not uniform, and are easily expanded when contacting the water. With the present invention, the disadvantages in the prior art are solved, and the moisture permeation performance of the fabric is improved.

Owner:KUNSHAN HUAYANG NEW MATERIAL

Erasable neutral ink and preparation method thereof

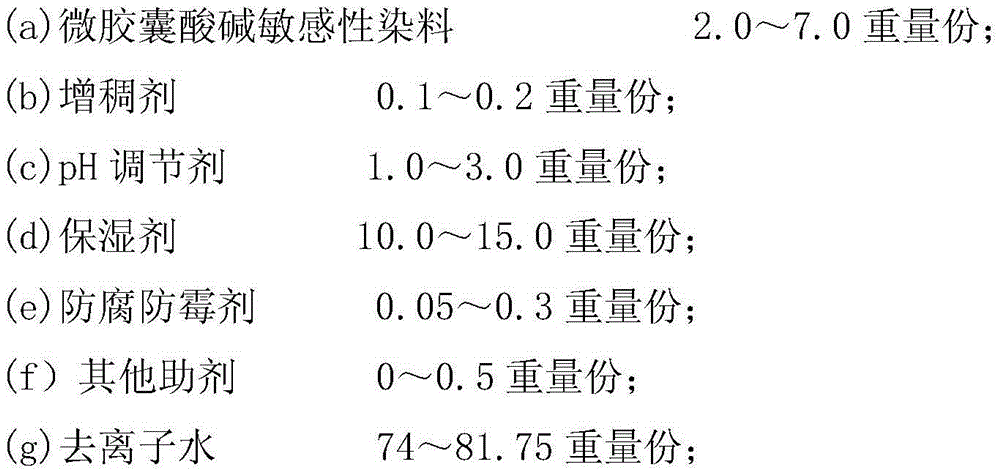

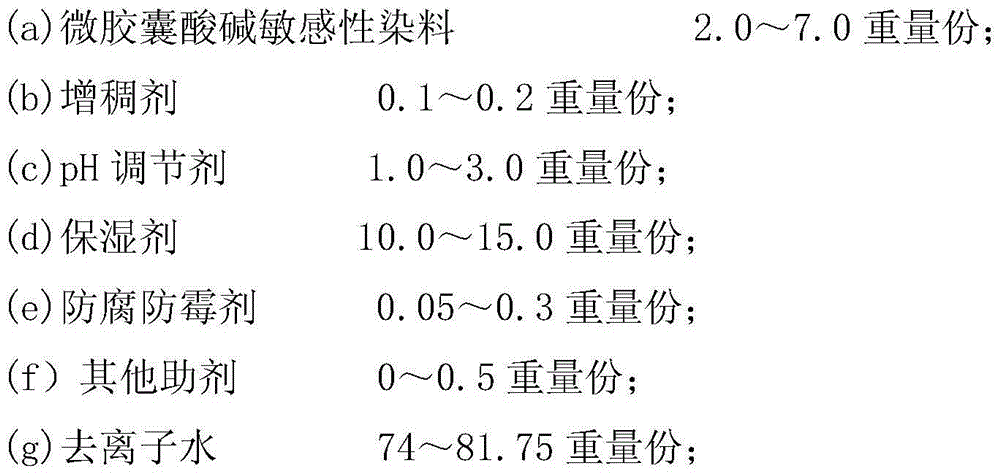

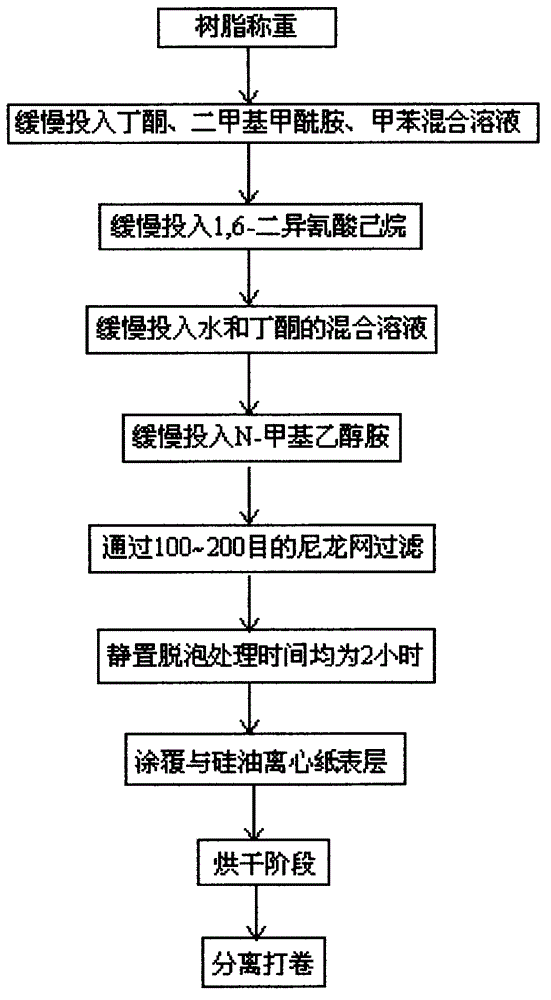

The invention provides an erasable neutral ink composition comprising a neutral ink component (A) and an erasable liquid component (B), wherein the component (A) comprises the following components in parts by weight: 2.0-7.0 parts of a microcapsule acid-alkali sensitive dye (a), 0.1-0.2 part of a thickening agent (b), 1.0-3.0 parts of a pH regulator (c), 10.0-15.0 parts of a humectant (d), 0.05-0.3 part of an antiseptic and anti-mildew agent (e), 0-0.5 part of other auxiliary agents (f) and 74-81.75 parts of deionized water (g), wherein the total weight of the components (a)-(g) accounts for 95-100% of the total weight of the composition, the viscosity of the neutral ink component is 1500-3000mPa.s, and the thixotropic value is more than or equal to 2.5; and the component (B) is an alkaline solution comprising an aqueous solution of one or more of sodium hydroxide, 2-amino-2-methyl-1-propanol, N-methylethanolamine, dimethylethanolamine, monoethanolamine, diethanolamine, triethanolamine, butyl ethanolamine, butyl diethanolamine, 2-amino-2-ethyl-1,3-propylene glycol and N-aminopropyl-methylethanolamine.

Owner:LOTUS STATIONERY

Degradable porous film for wind prevention, ventilation and bacteriostasis

InactiveCN102746526AGood waterproof and vapor permeabilityKeep dryLiquid temperatureMoisture permeation

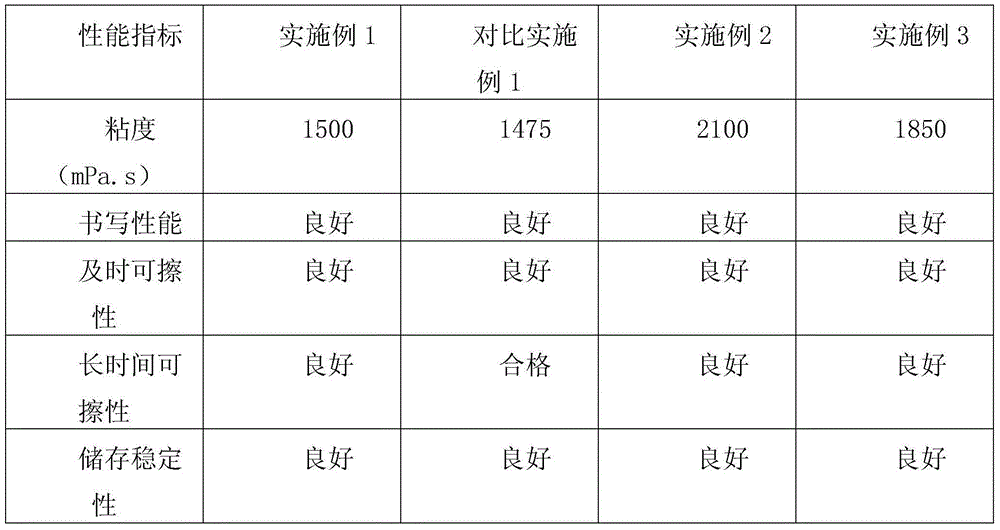

The invention discloses a degradable porous film for wind prevention, ventilation and bacteriostasis, which is prepared by the steps of: adjusting the liquid temperature of a reactor to 30 DEG C, and uniformly mixing butanone, dimethylformamide, toluene and polyurethane resin at the first stirring rate according to the mass ratio of 10:10:25:100 to form a first primary resin solution; slowly adding 1, 6-diisocyanate hexane into the first primary resin solution to form a first primary resin mixed solution; mixing the solvent which is formed by water and the butanone with the first primary resin solution to form the first primary resin mixed solution; mixing the regulated resin mixed solution with N-methylethanolamine; filtering the regulated first primary resin mixed solution by a nylon net of 100-200 meshes, so the filtered first primary resin mixed solution is obtained; and drying the macromolecular mixed resin which is scraped on the silicon oil release paper in a tensioning state by four stages. The porous film has uniform and dense micropores at a nanoscale of 50-200nm, has good wind prevention, moisture permeation, waterproofness, ventilation and excellent bacteriostasis, and is contributed to maintaining the long-term dryness of the film surface and wearing health when being used.

Owner:KUNSHAN HUAYANG NEW MATERIAL

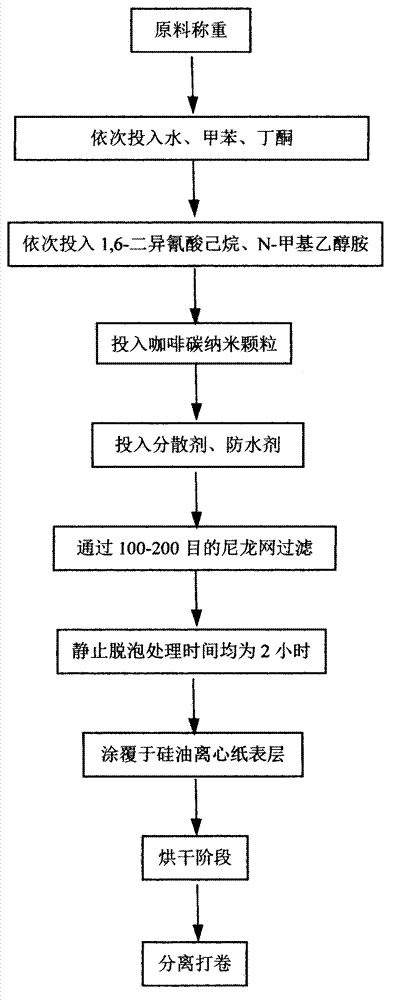

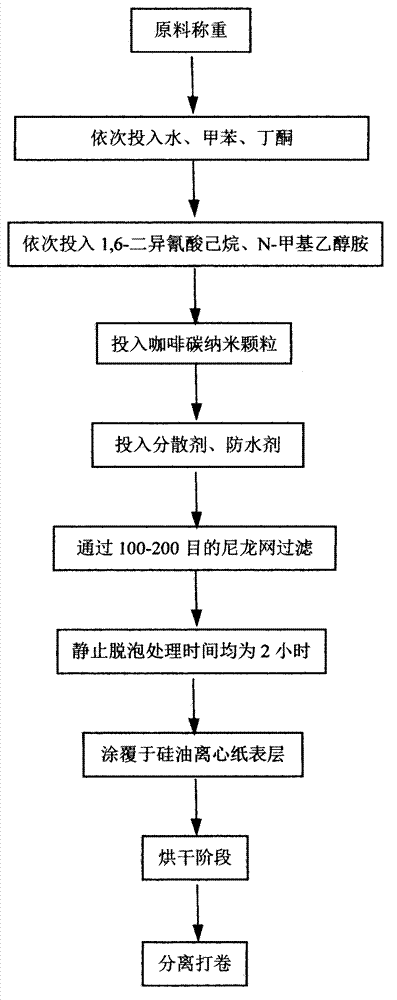

Nano coffee carbon function film with windproof air-permeable heat-accumulating warm-keeping effects

ActiveCN102775761AMeet the requirements of dry and comfortable wearingFar infraredHoneycomb structure

The invention discloses a nano coffee carbon function film with windproof air-permeable heat-accumulating warm-keeping effects. Polyurethane resin, water, toluene, butanone, 1,6- diisocyanato-cyclohexan, N-methyl ethanolamine, nano coffee carbon particles, a dispersing agent and a waterproofing agent are weighed according to the proportion of 100:40:20:20:3:1.5:10:1:0.5. The water, the toluene and the butanone are sequentially injected into a reaction kettle to be mixed to form a first resin solution. The 1,6- diisocyanato-cyclohexan and the N-methyl ethanolamine are sequentially injected into a first main resin solution to form a second resin solution. The nano coffee carbon particles are placed into the second resin solution. The dispersing agent and the waterproofing agent are sequentially added into macromolecule inorganic substance composite size. Prepared macromolecule inorganic substance is compounded to prepare film size. The nano coffee carbon function film is provided with even and compact nanoscale micropores, film indexes can reach 8000mm of hydrostatic pressure and 22000g / m<2> / 24h of moisture permeability, and the film combines a natural honeycomb structure of coffee carbon and a far infrared function and has the heat-accumulating warm-keeping antibacterial mite-inhabiting and far infrared health-care effects.

Owner:南通东屹高新纤维科技有限公司

Production process for waterproof shell fabric

ActiveCN103640275AGood moisture permeabilityGuaranteed waterproof performanceSynthetic resin layered productsMoisture permeabilityButanone

The invention discloses a production process for a waterproof shell fabric. The production process comprises the following steps: (1) preparing first slurry; (2) coating the surface of base cloth with the first slurry; (3) drying at 100 DEG C for 5-7 minutes; (4) mixing following components in parts by mass: 1-2 parts of lauryl aminoethyl sodium sulfate, 130 parts of polyurethane resin, 5-6 parts of 1,6-diisocyanatohexane, 60-65 parts of water, 17-19 parts of butanone, 6-7 parts of N-methylethanolamine and 40-45 parts of toluene; sieving with a nylon net with the size of 200 meshes; standing for 75 minutes under a vacuum condition to prepare second slurry; (5) coating the upper surface of a bottom coating with the second slurry to form a middle coating; (6) drying at 120 DEG C for 3-4 minutes; (7) preparing third slurry; (8) coating the upper surface of the middle coating with the third slurry to form a surface coating; (9) drying at 110 DEG for 2-3 minutes. According to the production process for the waterproof shell fabric, the moisture permeability of a textile is improved under the condition of guaranteeing the waterproof performance.

Owner:JIANGSU BOSBANI FASHION

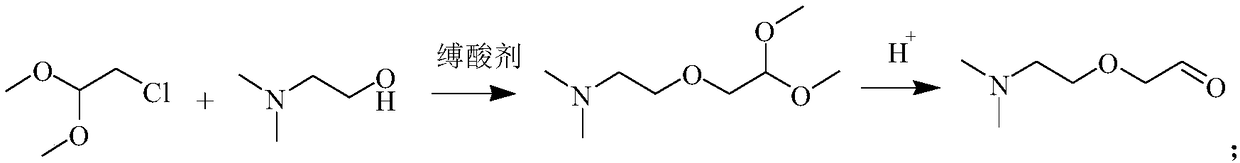

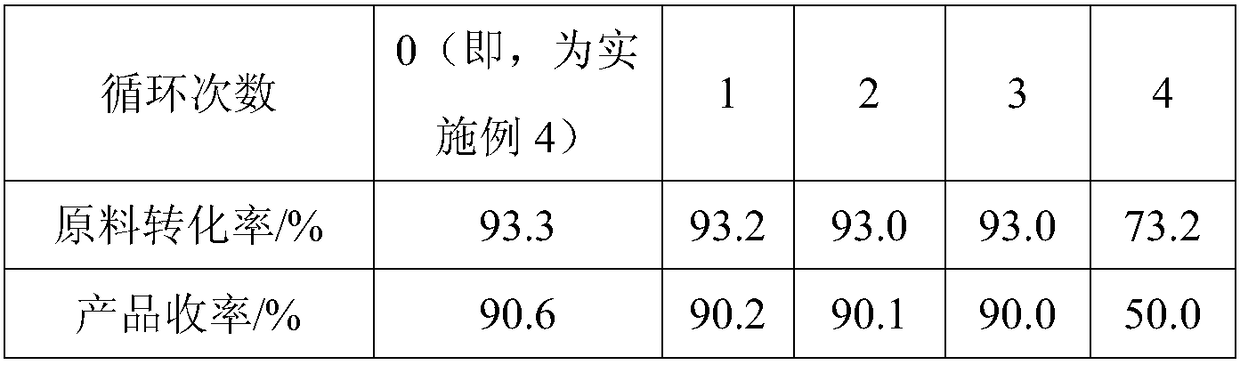

Preparation method of N,N,N'-trimethyl-N'-hydroxyethyl diaminoethyl ether

ActiveCN108250088AReduce pollutionAtom utilization is highOrganic compound preparationAmino-hyroxy compound preparationDimethyl acetalChloroacetaldehyde

The invention discloses a preparation method of N,N,N'-trimethyl-N'-hydroxyethyl diaminoethyl ether. The preparation method comprises the following steps: 1) in a solvent I, sequentially performing nucleophilic substitution and hydrolysis on N, N-dimethylethanolamine and chloroacetaldehyde dimethyl acetal which serve as raw materials to obtain 2-[2-(dimethylamino)ethyoxyl]acetaldehyde serving as an intermediate product; and 2) in a solvent II, mixing N-methylethanolamine and the 2-[2-(dimethylamino)ethyoxyl]acetaldehyde, performing hydrogenation amination on the mixture serving as a reaction system by taking Raney Ni as a catalyst to prepare the N,N,N'-trimethyl-N'-hydroxyethyl diaminoethyl ether. The N,N,N'-trimethyl-N'-hydroxyethyl diaminoethyl ether prepared by the method has the characteristics of simple process, low cost, high yield and low pollution.

Owner:安徽恒光聚氨酯材料有限公司

High efficient corrosive-proof paint

InactiveCN1793255AExtended service lifeImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsMethyl isobutyl ketoneTar

The invention discloses high active anticorrosive paint. Its material includes bisphenol A diglycidyl ether, epoxy resin with 371 equivalent weight, bisphenol A, N-methylethanolamine, and methyl isobutyl ketone, multi- isocyan phenolic ester, talc, and coat tar. It can effectively solve the current metal corrosion problem, and can play the action of protection against corrosion for hardware.

Owner:李巍

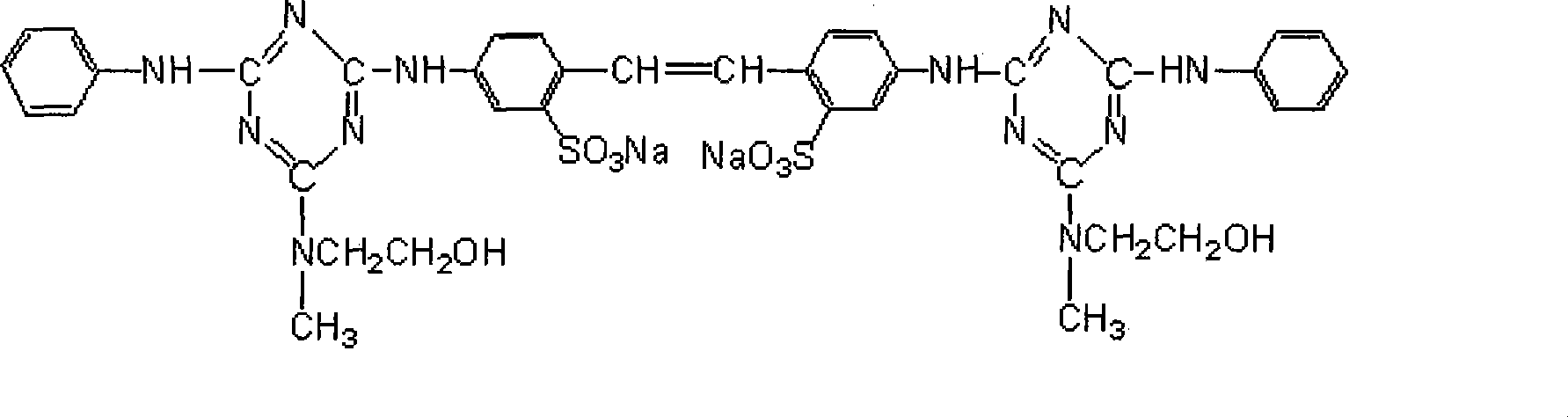

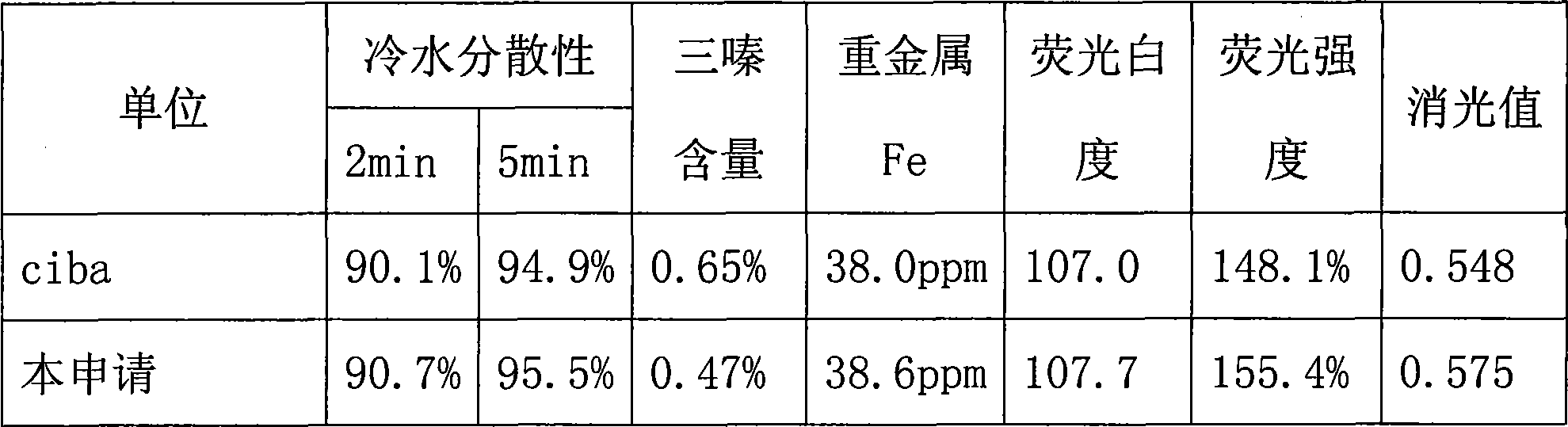

Process for producing fluorescent whitening agent 5BM

InactiveCN101429343AReduce pollutionImproved cold water dispersibilityStyryl dyesLuminescent compositionsIce waterWhitening Agents

The invention relates to a method for preparing a synthetic detergent and a ring whitening agent for printing industry, in particular to a method for preparing a fluorescent whitening agent 5BM. The method solves the problem that the product obtained through the prior method for processing and preparing the fluorescent whitening agent 5BM has low quality. The method comprises the following steps: cyanuric chloride and DSD acid are put into a reaction kettle and are added with ice water; the PH value of the mixture of the ice water, the cyanuric chloride and the DSD acid is regulated to between 1 and 1.5; the hydrochloric acid generated in the reaction is neutralized; the PH value is regulated to between 6 and 6.5; after the amido value of the DSD acid disappears, the hydrochloric acid is added with aniline; after the aniline disappears, N-methylethanolamine is added to the mixture; the PH value is finally regulated to between 10 and 12; the mixture is cooled to the temperature of 5 DEG C through the ice water so that a target product is precipitated out; and the target product is filtered, dried and pulverized to obtain the 5BM product.

Owner:山西青山化工有限公司

Epoxy-polyurethane anti-corrosive paint and preparation method thereof

InactiveCN101760120AEasy to sprayGood application effectAnti-corrosive paintsPolyurea/polyurethane coatingsSolubilityPolyester

The invention relates to an epoxy-polyurethane anti-corrosive paint and a preparation method thereof, and the epoxy-polyurethane anti-corrosive paint comprises the components in parts by weight: polyester polyol A and paint B, wherein A comprises 85.5 parts of bisphenol A glycidyl ether (with the epoxy equivalent weight of 371) which is the product of addition reaction between 1mol of bisphenol A and 4mol of epoxy chloropropane, 14.5 parts of bisphenol A glycidyl ether (with the epoxy equivalent weight of 188), 27.5 parts of bisphenol A and 5 parts of N-methylethanolamine; and B comprises 100 parts of polyether polyol resin, 64 parts of polyisocyanate, 50 parts of methylisobutylketone, 50 parts of coal tar and 50 parts of talcum powder. The paint has excellent corrosion resistance and flexibility, and especially excellent organic solvent dissolubility and mixed solubility with asphalt or other substitutions, thus being suitable for being taken as anti-corrosive paint and heavy-duty coating.

Owner:李岳

Under-coating paint used for moisture permeable waterproof fabrics and preparation technology

ActiveCN103215809ASolve the weakness that it is easy to expand when exposed to waterGood moisture permeabilityFibre treatmentButanoneToluene

The invention discloses an under-coating paint used for moisture permeable waterproof fabrics and a preparation technology, the under-coating paint comprises polyurethane resin, butanone, toluene, water, 1,6-diisocyanatohexane and N-methyl ethanolamine; the preparation technology comprises the following steps: uniformly mixing butanone, water and polyurethane resin to form a main resin solution; adding N-methyl ethanolamine in the main resin solution; placing a mixed liquid of butanone and toluene in the main resin solution to form a main resin mixed solution; mixing 1,6-diisocyanatohexane and the main resin mixed solution according to mass proportion of 100:1.5-2.5 to form the adjusted main resin mixed solution; mixing water and butanone to form a solvent, placing the solvent in the adjusted main resin mixed solution by dividing at least six times for uniformly mixing; filtering the adjusted main resin mixed solution through a nylon net; and standing the filtered main resin mixed solution for at least 2 hours for deaeration treatment. The coating fabrics formed by the under-coating paint has uniform micropore, and is difficult to be expanded when contacting water, so that the moisture permeable performance of the fabric can be enhanced.

Owner:KUNSHAN HUAYANG NEW MATERIAL

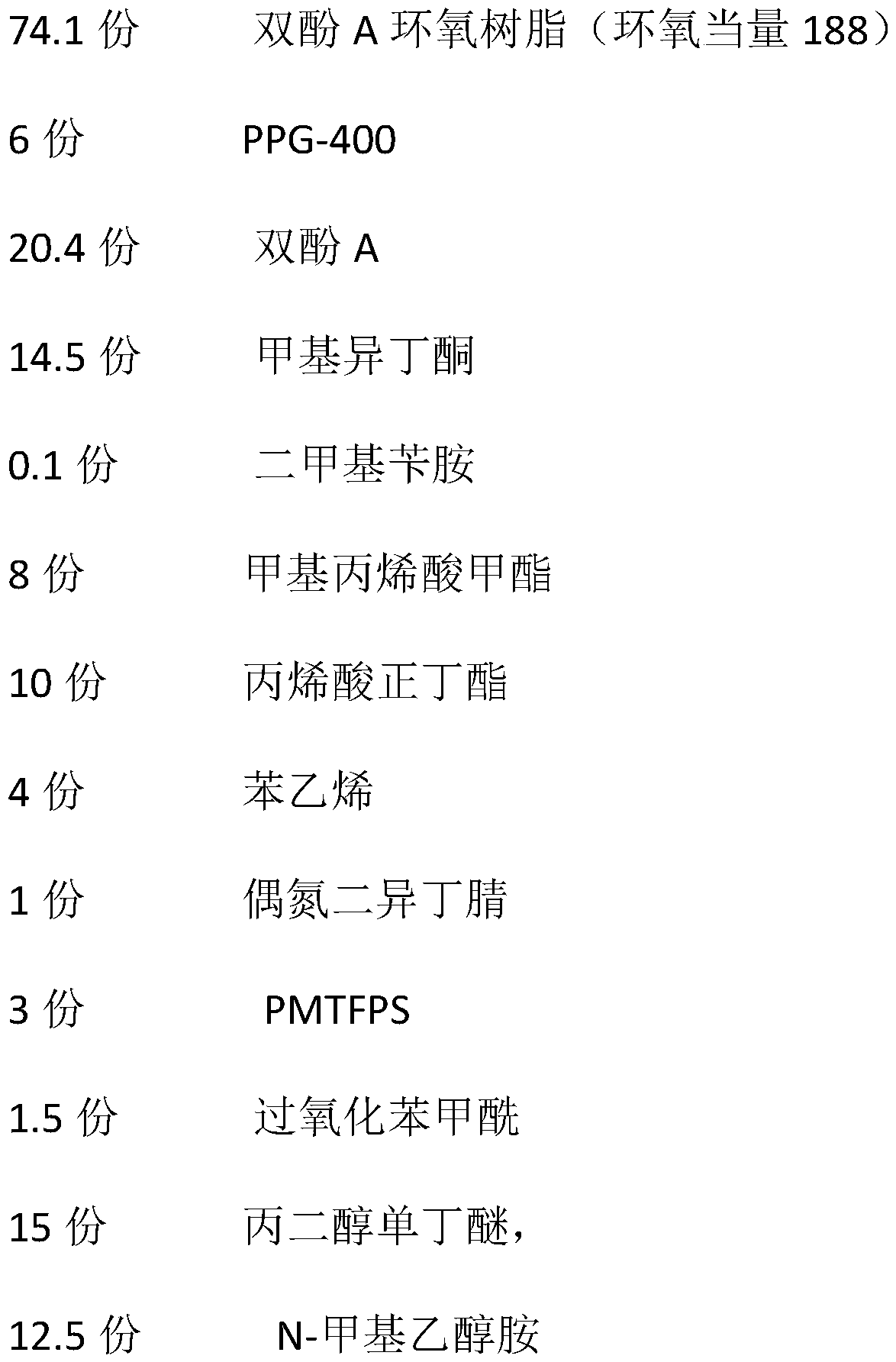

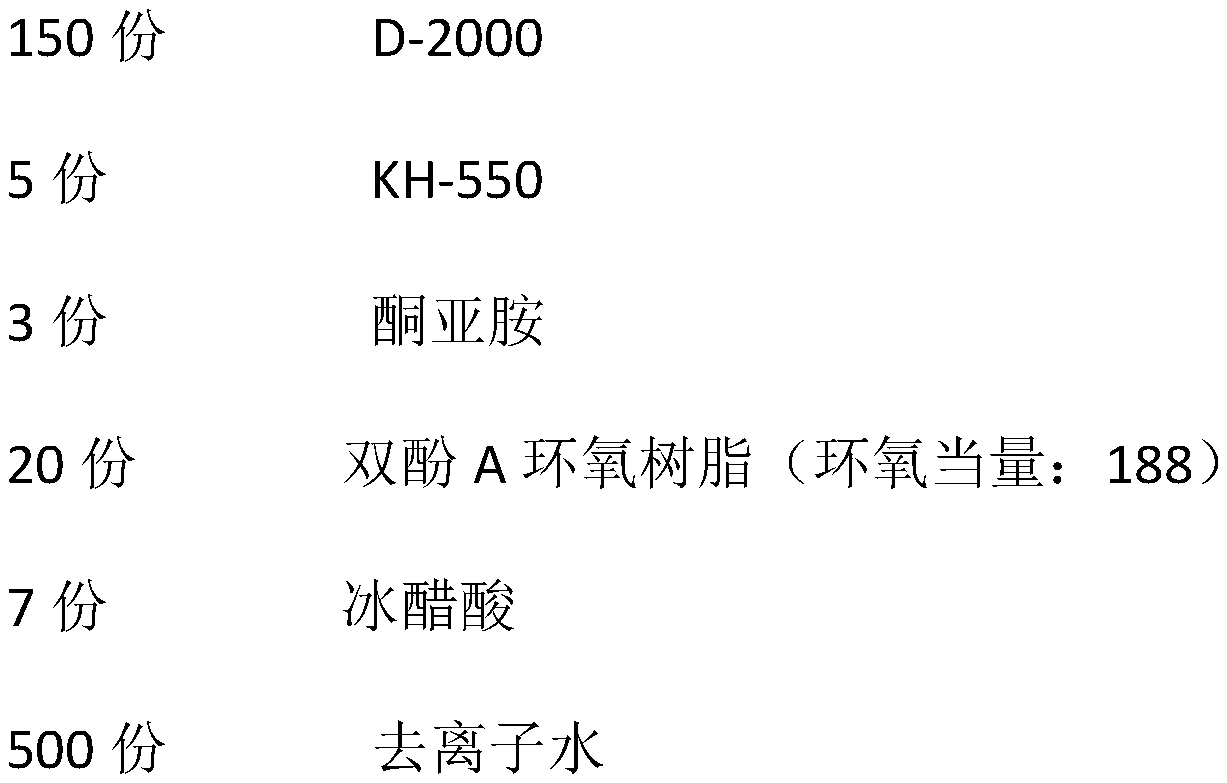

Noise-reducing epoxy acrylic resin, noise-reducing emulsion and noise-reducing waterborne coating

ActiveCN110437391AGood slipperinessImprove sound absorption and noise reductionPolyurea/polyurethane coatingsBenzoyl peroxideAcrylic resin

The invention relates to a noise-reducing epoxy acrylic resin, a noise-reducing emulsion and a noise-reducing waterborne coating. The epoxy acrylic resin is prepared from, by weight, 74.1 parts of a bisphenol A epoxy resin with an epoxy equivalent of 188, 6 parts of PPG-400, 20.4 parts of a bisphenol A, 14.5 parts of methyl isobutyl ketone, 0.1 part of benzyldimethylamine, 8 parts of methyl methacrylate, 10 parts of n-butyl acrylate, 4 parts of styrene, 1 part of azobisisobutyronitrile, 3 parts of PMTFPS, 1.5 parts of benzoyl peroxide, 15 parts of propylene glycol monobutyl ether and 12.5 parts of N-methylethanolamine, the emulsion contains the epoxy acrylic resin, and the waterborne coating contains the epoxy acrylic emulsion. The epoxy acrylic resin, the emulsion and the waterborne coating of the present invention have sound absorbing and noise reducing effects.

Owner:HAOLISEN CHEM TECH (JIANGSU) CO LTD

Polyurethane slurry for producing PU (Polyurethane) stripped fur shell fabric

InactiveCN104045998AUniform microporousNot easy to expandTextiles and paperEnvironmental resistanceSlurry

The invention discloses polyurethane slurry for producing a PU (Polyurethane) stripped fur shell fabric. The polyurethane slurry is prepared from the following components in parts by weight: 100 parts of hydrolysis-resistant polyurethane, 5-7 parts of dimethyl acryl methylamine, 20 parts of butanone, 18-20 parts of toluene, 20 parts of deionized water, 1 part of N-methyl ethanol amine, 3 parts of di-iso-octyl maleate sodium sulfonate and 5-7 parts of dye paste. The coating shell fabric formed by the polyurethane slurry is uniform in micropore, and the polyurethane slurry is not easy to swell with water, thereby improving the water vapor permeability of the fabric. In addition, the polyurethane slurry can be freely colored, and the physical indexes such as color fastness, degree of sunlight, peel strength and tear strength can be randomly improved according to the demands of customers. The polyurethane slurry is free from extraneous odor, light in weight, less in possibility of hardening with water, perspiring, antibacterial and mildew-proof, and meets the environmental requirements.

Owner:罗静

Copper surface organic solder preservative and application thereof

ActiveCN105772989AImprove stabilityImprove uniformityWelding/cutting media/materialsSoldering mediaOrganic filmAlcohol

The invention discloses copper surface organic solder preservative and an application thereof. The organic solder preservative comprises a solution containing organic film forming matter, an adjusting additive and a buffering agent; the organic film forming matter is an imidazole compound; the buffering agent is one or more of 2-amidogen-2-methyl-1-propyl alcohol, 2-(butyl amine) ethyl alcohol and N-methylethanolamine or is an aqueous solution of one or more of 2-amidogen-2-methyl-1-propyl alcohol, 2-(butyl amine) ethyl alcohol and N-methylethanolamine. According to the copper surface organic solder preservative, through formula improvement, the dissolving property of the film forming matter and stability of a reaction system can be improved, accordingly, the film forming quality of the copper surface is improved, and the film forming efficiency is improved.

Owner:深圳市天泽科技实业有限公司

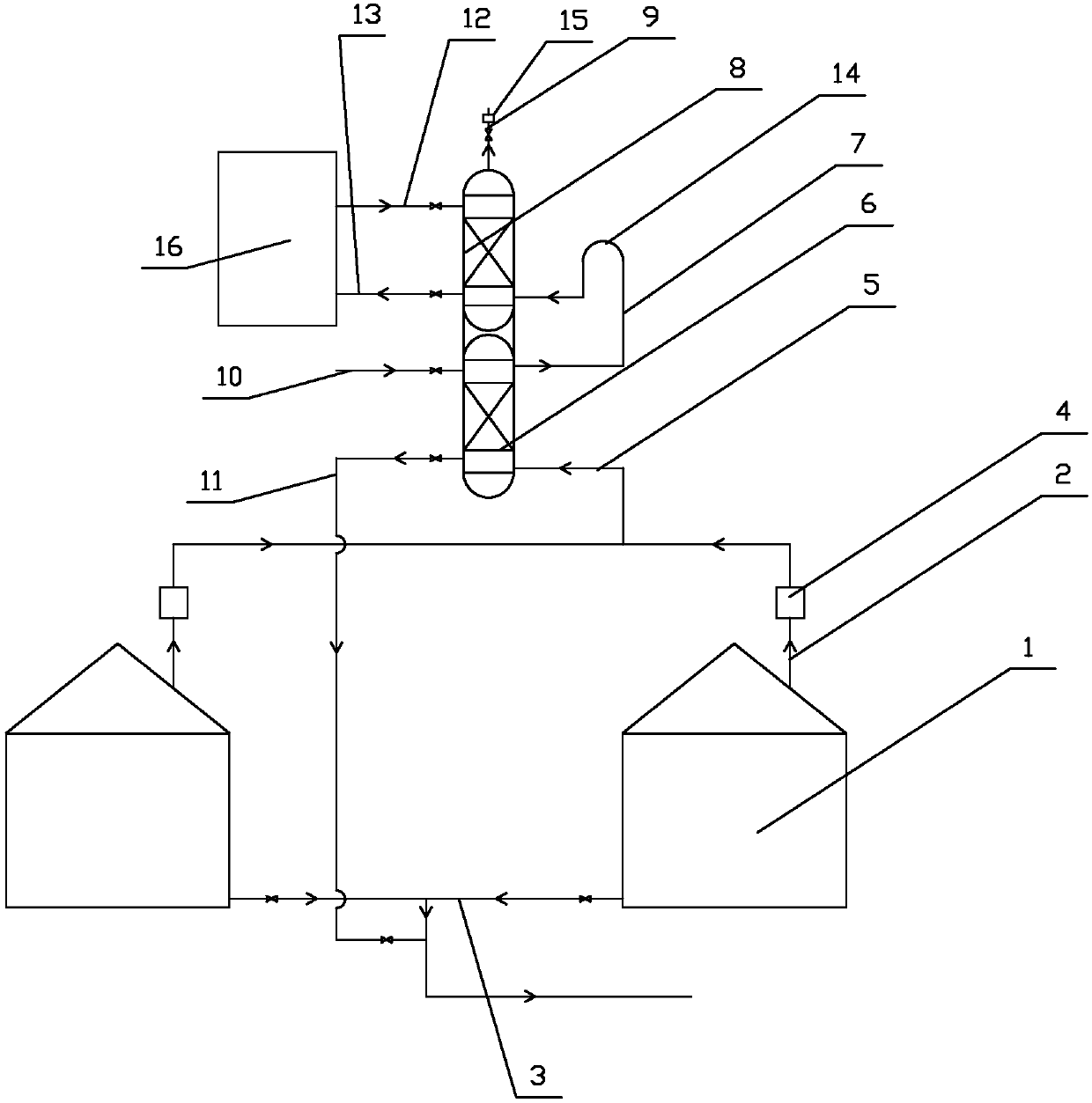

Acid water tank deodorization system for sulfur recovery device

PendingCN107617312AEasy to separateAvoid inactivationDispersed particle separationSystems designWater discharge

The invention relates to an acid water tank deodorization system for a sulfur recovery device. The system comprises a plurality of acid water tanks, wherein a blow-down pipe is arranged on the top ofeach acid water tank; a water discharge pipe is arranged at the bottom of each acid water tank; the blow-down pipes are connected with a water seal tank; an outlet of the water seal tank is connectedwith the bottom of a first washing tower through a first rich gas pipe; the top of the first washing tower is connected with the bottom of a second washing tower through a first poor gas pipe; the blow-down pipe is arranged on the top of the second washing tower; a first absorbent poor liquid pipe is arranged on the top of the first washing tower; a first absorbent rich liquid pipe is arranged atthe bottom of the first washing tower; a second absorbent poor liquid pipe is arranged on the top of the second washing tower; a second absorbent rich liquid pipe is arranged at the bottom of the second washing tower. The system has the advantages that the system design is reasonable; hydrogen sulfide and ammonia gas are respectively subjected to adsorption treatment; in addition, the ammonia gasis firstly removed; the N-methylethanolamine inactivation is prevented. A foreign smell source of the whole device region is controlled by the system; the pollution and the potential safety hazards are eliminated; the environment-friendly benefits are huge.

Owner:山东省岚桥石化有限公司

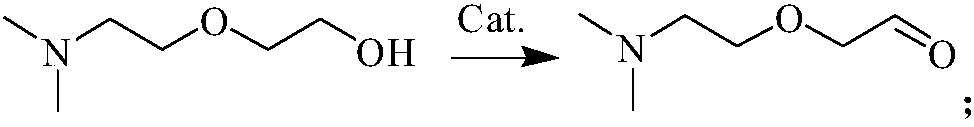

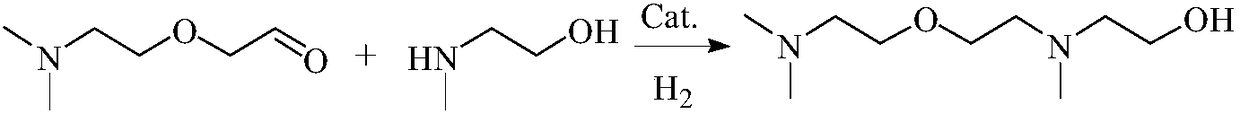

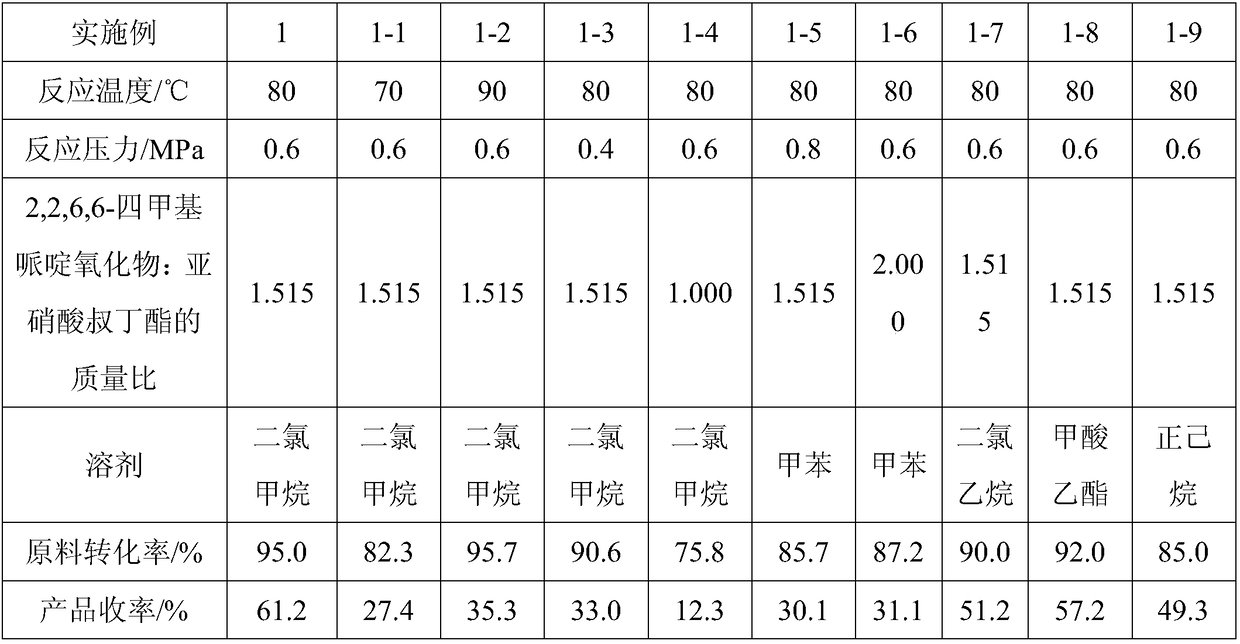

Synthesis method of N, N, N'-trimethyl-N'-hydroxyethyl diaminoethyl ether

InactiveCN108084040AReduce pollutionNo pollution in the processOrganic compound preparationAmino-hyroxy compound preparationNitriteSynthesis methods

The invention discloses a synthesis method of N, N, N'-trimethyl-N'-hydroxyethyl diaminoethyl ether. The synthesis method comprises the following steps of: in a solvent I, adopting dimethylaminoethoxyethanol as a raw material, and under a catalytic system of 2, 2, 6, 6-tetramethyl piperidinoxide-FeCl3-tertbutyl nitrite, utilizing oxygen gas to oxidize the dimethylaminoethoxyethanol into 2-[2-(dimethylamino)ethoxy]acetaldehyde; in a solvent II, mixing N-methylethanolamine with the 2-[2-(dimethylamino) ethoxy]acetaldehyde, adopting Raney Ni as a catalyst, adopting the above mixture as a reactionsystem to carry out hydrogenation and amination, and preparing the N, N, N'-trimethyl-N'-hydroxyethyl diaminoethyl ether. The N, N, N'-trimethyl-N'-hydroxyethyl diaminoethyl ether synthesized by adopting the synthesis method has the characteristics of simple process, low cost, high yield and less pollution.

Owner:ZHEJIANG UNIV

Imitation leather fabric production method

The invention discloses an imitation leather fabric production method. The imitation leather fabric production method includes the following steps that first, base fabric is selected and reeled up; second, the base fabric is evenly coated with resin material; third, the resin material is solidified; fourth, extrusion and water washing are performed; fifth, coating release paper is evenly coated with prepared polyurethane slurry, wherein the polyurethane slurry contains butanone and N-methyl ethanolamine; sixth, the coating release paper is attached to the base fabric and totally dried again; seventh, the release paper is separated. The imitation leather fabric production method is compact, reasonable and capable of effectively improving production efficiency; the coating fabric formed through the polyurethane slurry is even in micropore and not prone to expansion with water; besides, free coloring can be performed, physical indexes such as color fastness, illuminance, peel strength and tear strength can be freely adjusted, and thus the produced imitation leather fabric can be more excellent in performance.

Owner:罗静

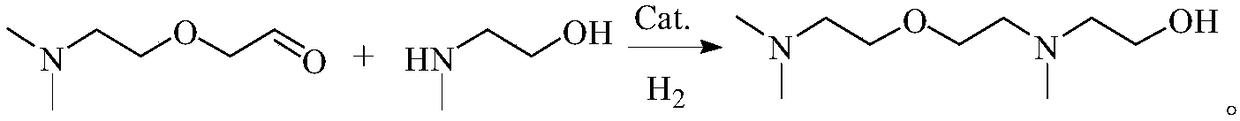

Catalyst for catalytically synthesizing N-methyl ethanol amine compound and application thereof

ActiveCN103071534BEasy to makeGood dispersionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSubstance amountTriphenylphosphine

The invention provides catalyst for catalytically synthesizing an N-methyl ethanol amine compound and a preparation method thereof. The catalyst adopts a mesopore Al2O3 as a carrier; after modifying the carrier, alkali metal salt is dipped in organic solution of triphenylphosphine, and is dried to obtain the catalyst; and in the catalyst, the substance amount ratio of thetriphenylphosphine to an alkali metal element to an aluminum element is 1: (2.5-7.5): (4.5-9.3). The catalyst has the characteristics of simplicity in preparation, excellent dispersivity, large specific surface area, long service life and the like. The catalyst is applied in the reaction of N methyl ethanol amine organic amine (MMEA, DMEA), so that the conversion rate is high, and the selectivity is good.

Owner:NINGBO ZHETIE JIANGNING CHEM +1

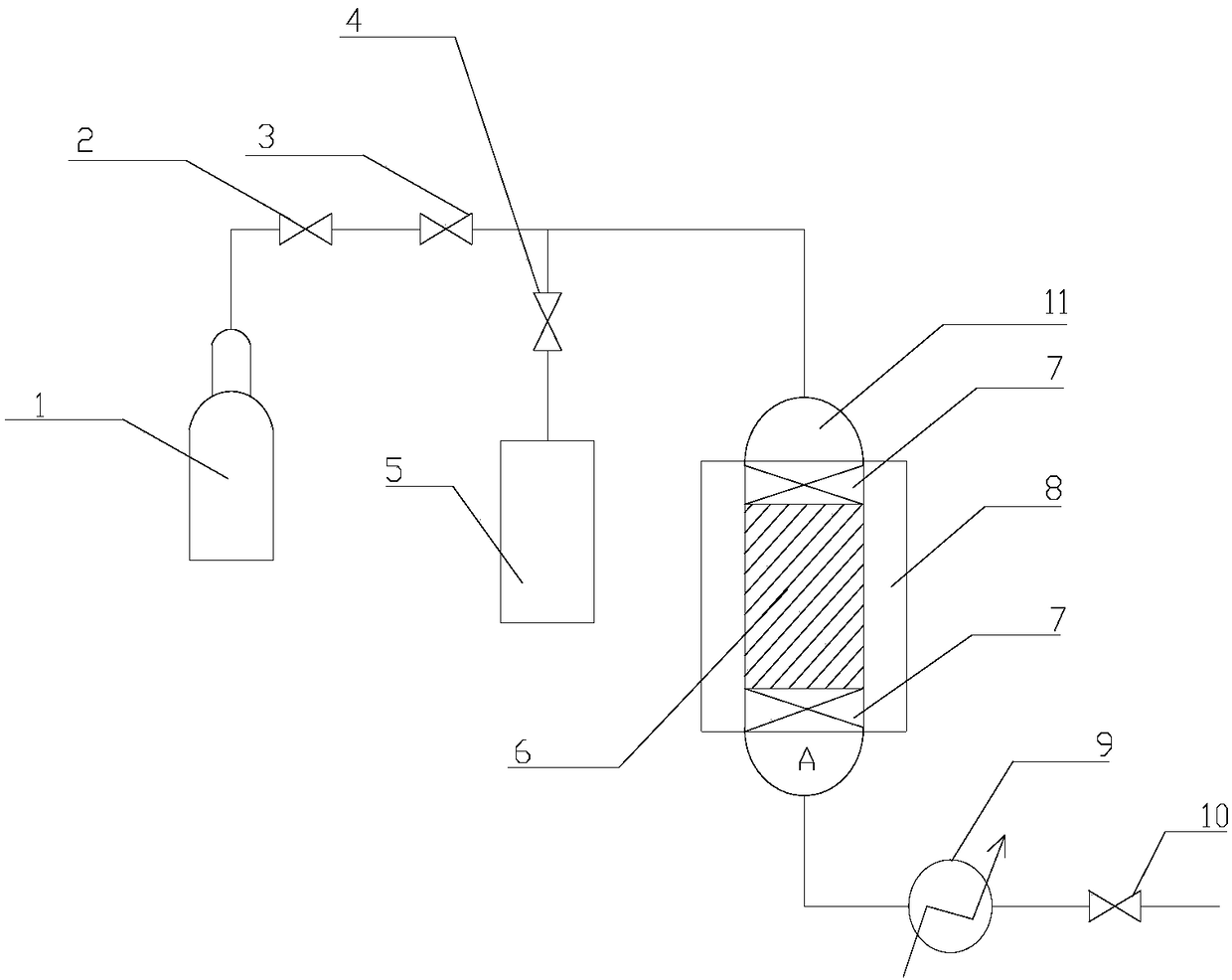

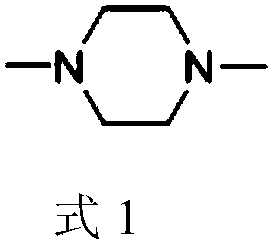

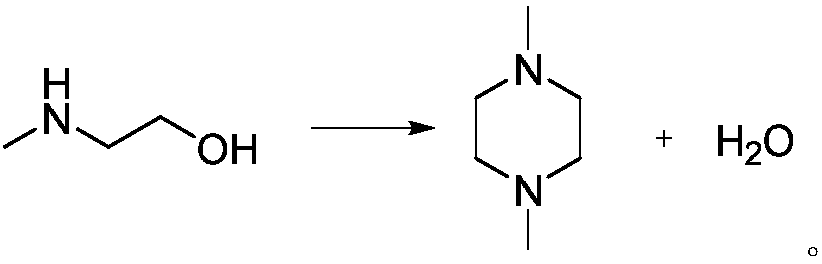

Method of synthesizing 1,4-dimethylpiperazine and catalyst used

InactiveCN108187679ALow priceHigh activityOrganic chemistryCatalyst activation/preparationHydrogen pressureReaction temperature

The invention discloses a supported catalyst for synthesizing 1,4-dimethylpiperazine. Roasted spherical gamma-Al2O3 serves as a carrier, and active components, cuprum and nickel, are loaded on the carrier. The invention further provides a method of synthesizing 1,4-dimethylpiperazine by using the supported catalyst. The method comprises the steps of putting the supported catalyst in a fixed-bed reactor, performing activation by the action of hydrogen, injecting a raw material, N-methylethanolamine into a vaporization chamber via a sampling pump for vaporization, regulating a flow rate of the sampling pump, allowing volumetric space velocity to be 0.1-0.5h<1>, regulating hydrogen pressure to allow reaction pressure to be 0.2-2.0MPa, allowing reaction temperature to be 200-300 DEG C, allowing a product to flow out from the bottom of the fixed-bed reactor, collecting the product after condensation by a condenser, and performing rectification at atmospheric pressure to form 1,4-dimethylpiperazine. The method is simple in technology, appropriate in reaction condition, low in production cost and higher in yield, and the adopted catalyst is low in cost, good in activity and long in service life.

Owner:之江(四川)高新材料应用技术研究院有限公司

Imitation leather fabric slurry production method

The invention discloses an imitation leather fabric slurry production method. At 25 DEG C in work, 100 parts of polyurethane, 5 parts of dimethyl formamide, 20 parts of butanone, 20 parts of deionized water, 1 part of N-methylethanolamine, 1 part of dioctyl sodium sulfosuccinate and 7 parts of dye cream are mixed by mass to prepare a mixed solution, and the obtained solution is stirred and filtered and stands still in sequence. The imitation leather fabric slurry production method has the advantages of being easy and convenient to operate, simple in processing technology and convenient to implement concretely. Slurry produced with the imitation leather fabric slurry production method can be used for producing imitation leather fabric, and the produced imitation leather fabric is attractive in appearance, light in weight, good in waterproofness and moisture permeability, firm, durable, not prone to ageing, not prone to expansion with water, smooth and flat in surface, free from extraneous odors, capable of draining sweat, antibacterial and capable of preventing mildew and has fewer folds.

Owner:杨帆

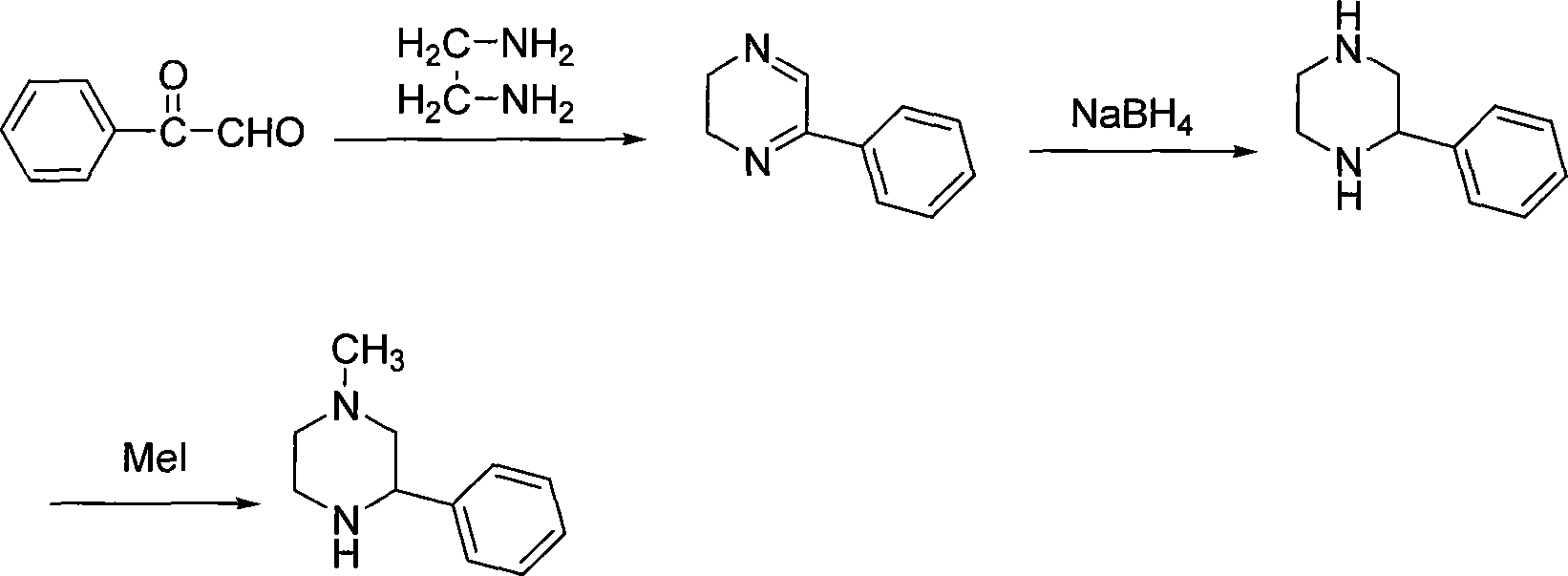

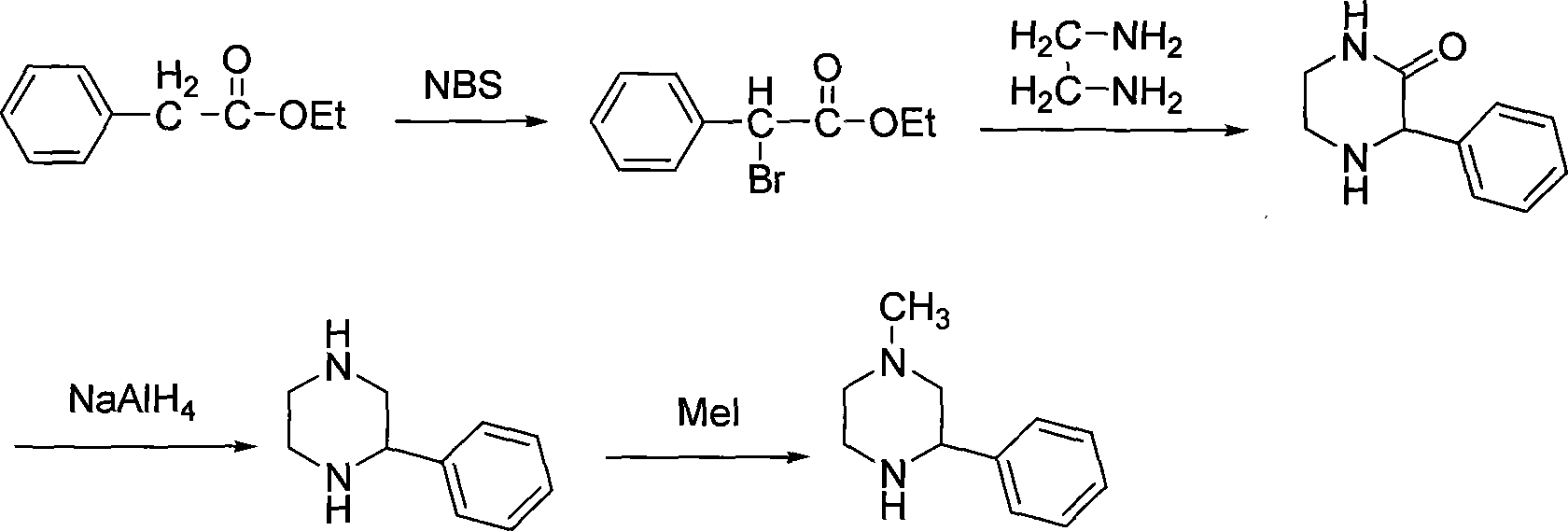

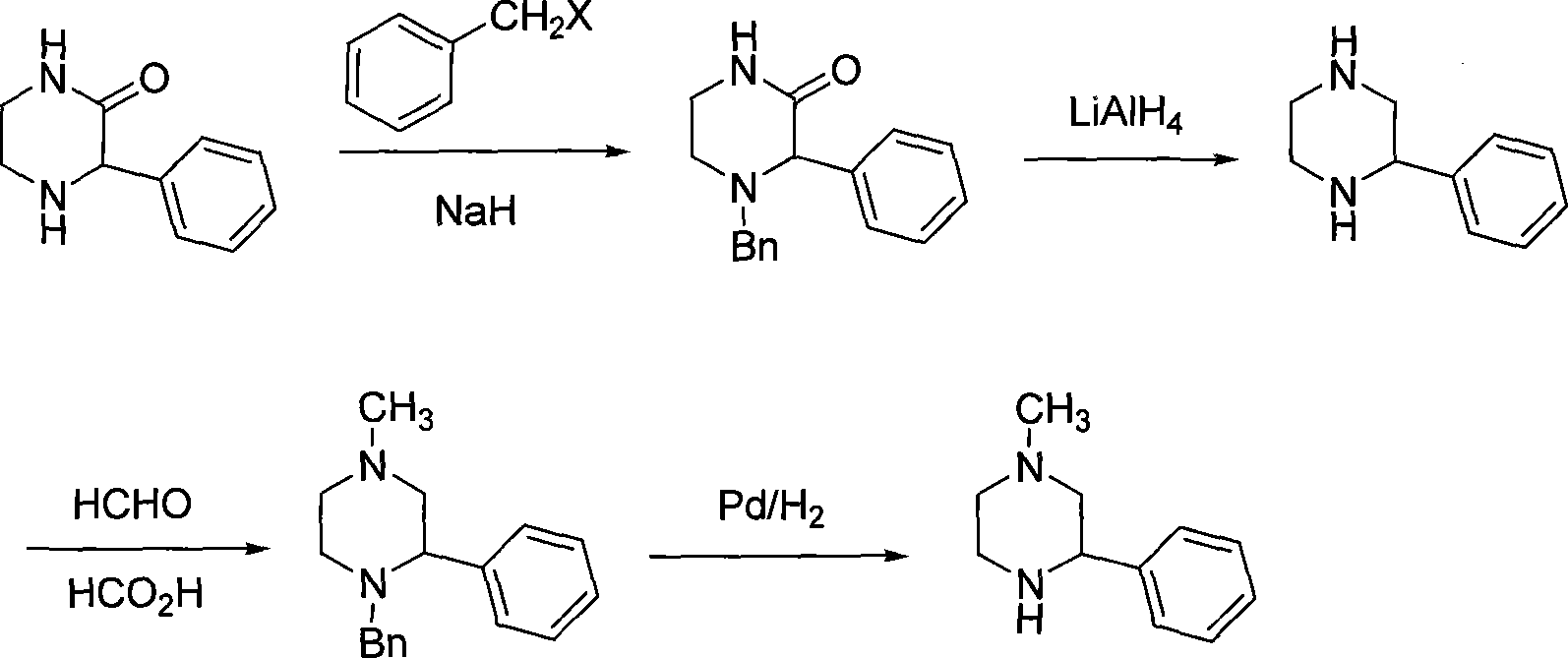

Preparation of medicament intermediate 1-methyl-3-phenyl piperazine

ActiveCN101440067BReduce the amount of alkaliDoes not require high vacuum distillationOrganic chemistryEpoxyPhenylpiperazine

The invention relates to a method for preparing a medicine intermediate, namely 1-methyl-3-phenyl-piperazine. Epoxy phenylethane and N-methyl ethanolamine react for ring opening in a methylbenzene solution and further react with thionyl chloride to obtain N-(2- chloroethyl)-N-methyl-2-chloro-2-phenylethylamine hydrochloride, the hydrochloride reacts with toluene sulfonamide and sodium hydroxide in a DMF solution to obtain 1-methyl-4-p-toluenesufonyl-3-phenylpiperazine, the 1-methyl-4-p-toluenesufonyl-3-phenylpiperazine reacts with concentrated hydrochloric acid to remove sulfonyl, and a product is obtained through neutralization extraction and recrystallization. Compared with the prior art, the method for preparing the 1-methyl-3-phenyl-piperazine has the advantages of low cost of selected raw materials, cost conservation, few synthesis steps, convenient and safe operation, simple post-treatment, high reaction yield, high product purity, good quality, and suitability for industrialized application.

Owner:上海津力药业股份有限公司

Moisture-permeable waterproof film used for fabric and fabrication process thereof

ActiveCN102555380BSolve the weakness that it is easy to expand when exposed to waterGood moisture permeabilitySynthetic resin layered productsLaminationSlurryMoisture

The invention discloses a moisture-permeable waterproof film used for a fabric and a fabrication process thereof. According to the invention, a primary coating comprises polyurethane resin, butanone, toluene, water, hexane diisocyanate and N-methylethanolamine, and a first and second surface coatings comprise polyurethane resin, butanone, toluene, water and N-methylethanolamine. The fabrication process comprises the following steps: mixing hexane diisocyanate with main resin; mixing water with butanone to form a solvent which is put into a main resin mixed solution in at least six steps; filtering the mixed solution with a nylon net so as to obtain a filtered main resin mixed solution and carrying out deaeration treatment so as to form a primary coating slurry; preparing a surface coating slurry with the viscosity of a conjugate solution being 3500 to 6000 mpas; coating the primary coating slurry on the surface of release paper to form the primary coating, with coated weight being 4 to 6 g / m<2>; coating the surface coating slurry on the surface of the primary coat to form the surface coatings; and drying the release paper with the surface coatings and peeling the surface coatings off the release paper. According to the invention, the disadvantages that existing hydrophilic moisture permeable processing coating fabrics have nonuniform micropores and easily swell when contacting with water are overcome, and therefore, moisture permeable performance of a fabric itself is improved.

Owner:KUNSHAN HUAYANG NEW MATERIAL

Primer slurry for moisture-permeable waterproof fabric and its preparation process

ActiveCN103215809BSolve the weakness that it is easy to expand when exposed to waterGood moisture permeabilityFibre treatmentEthanolaminesSlurry

The invention discloses an under-coating paint used for moisture permeable waterproof fabrics and a preparation technology, the under-coating paint comprises polyurethane resin, butanone, toluene, water, 1,6-diisocyanatohexane and N-methyl ethanolamine; the preparation technology comprises the following steps: uniformly mixing butanone, water and polyurethane resin to form a main resin solution; adding N-methyl ethanolamine in the main resin solution; placing a mixed liquid of butanone and toluene in the main resin solution to form a main resin mixed solution; mixing 1,6-diisocyanatohexane and the main resin mixed solution according to mass proportion of 100:1.5-2.5 to form the adjusted main resin mixed solution; mixing water and butanone to form a solvent, placing the solvent in the adjusted main resin mixed solution by dividing at least six times for uniformly mixing; filtering the adjusted main resin mixed solution through a nylon net; and standing the filtered main resin mixed solution for at least 2 hours for deaeration treatment. The coating fabrics formed by the under-coating paint has uniform micropore, and is difficult to be expanded when contacting water, so that the moisture permeable performance of the fabric can be enhanced.

Owner:KUNSHAN HUAYANG NEW MATERIAL

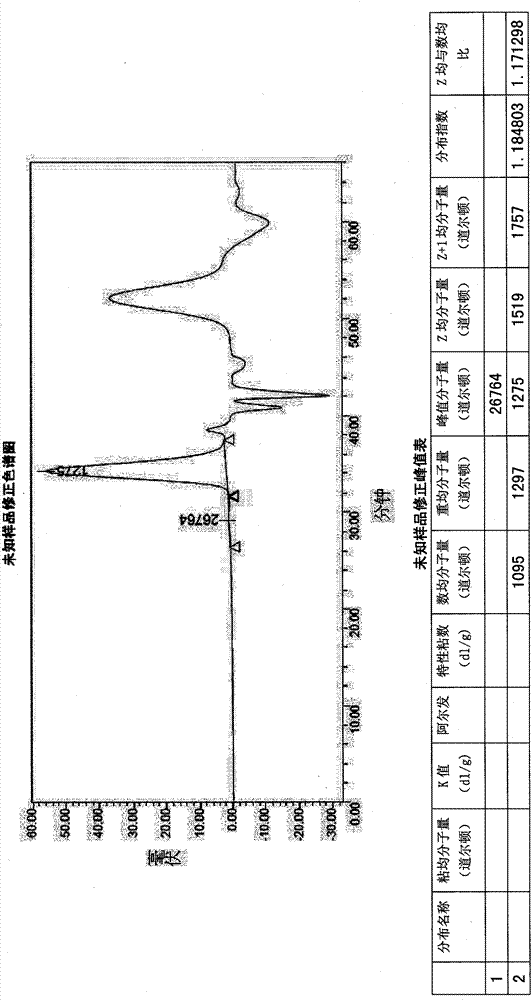

Hydroxyl-terminated polyacrylate oligomer as well as preparation method and application thereof

The invention relates to a preparation method of hydroxyl-terminated polyacrylate oligomers, which comprises the following steps: preparing low molecular weight polyacrylate oligomers with controllable molecular weight, such as polybutylacrylate, polyethylacrylate, oly(isooctyl acrylate), polymethyl methacrylate, a block copolymer of butyl acrylate and methyl methacrylate, a block copolymer of themethyl methacrylate and dimethylaminoethyl methacrylate, and the like by adopting atom transfer radical polymerization (ATRP) and using organic halide as an initiating agent; and then carrying out terminal group modification on the polymers by N-methylethanolamine to obtain the hydroxyl-terminated polyacrylate oligomers with controllable molecular weight. The prepared hydroxyl-terminated polyacrylate oligomers can be used for the production of polyurethane. Because the molecular weight of the hydroxyl-terminated polyacrylate oligomers is controllable, a polyurethane material with special performance can be prepared.

Owner:溧阳常大技术转移中心有限公司

Nano coffee carbon function film with windproof air-permeable heat-accumulating warm-keeping effects

ActiveCN102775761BMeet the requirements of dry and comfortable wearingFar infraredHoneycomb structure

The invention discloses a nano coffee carbon function film with windproof air-permeable heat-accumulating warm-keeping effects. Polyurethane resin, water, toluene, butanone, 1,6- diisocyanato-cyclohexan, N-methyl ethanolamine, nano coffee carbon particles, a dispersing agent and a waterproofing agent are weighed according to the proportion of 100:40:20:20:3:1.5:10:1:0.5. The water, the toluene and the butanone are sequentially injected into a reaction kettle to be mixed to form a first resin solution. The 1,6- diisocyanato-cyclohexan and the N-methyl ethanolamine are sequentially injected into a first main resin solution to form a second resin solution. The nano coffee carbon particles are placed into the second resin solution. The dispersing agent and the waterproofing agent are sequentially added into macromolecule inorganic substance composite size. Prepared macromolecule inorganic substance is compounded to prepare film size. The nano coffee carbon function film is provided with even and compact nanoscale micropores, film indexes can reach 8000mm of hydrostatic pressure and 22000g / m<2> / 24h of moisture permeability, and the film combines a natural honeycomb structure of coffee carbon and a far infrared function and has the heat-accumulating warm-keeping antibacterial mite-inhabiting and far infrared health-care effects.

Owner:南通东屹高新纤维科技有限公司

Surface coating slurry used for moisture permeable waterproof fabrics and preparation technology

ActiveCN103214682ASolve the weakness that it is easy to expand when exposed to waterGood moisture permeabilityFibre treatmentEthanolaminesSlurry

The invention discloses a surface coating slurry used for moisture permeable waterproof fabrics and a preparation technology, the surface coating slurry comprises polyurethane resin, butanone, toluene, water and N-methyl ethanolamine; the preparation technology comprises the following steps: uniformly mixing butanone, water and polyurethane resin to form a main resin solution according to mass proportion of 66-68:3-5:29; placing a mixed liquid of butanone and toluene in the main resin solution to form a main resin mixed solution; mixing N-methyl ethanolamine and main resin mixed solution to form adjusted main resin mixed solution; uniformly mixing water and butanone according to mass proportion of 9:1 to form a solvent; mixing the solvent and the adjusted main resin mixed solution; passing the main resin mixed solution adjusted by the step 5 through a nylon net with 100-200 meshes for filtering to obtain the filtered main resin mixed solution; and standing the filtered main resin mixed solution for at least 2 hours for deaeration treatment. The coating fabrics formed by the surface coating slurry has uniform micropore, and is difficult to be expanded when contacting water.

Owner:KUNSHAN HUAYANG NEW MATERIAL

Catalyst for catalytically synthesizing N-methyl ethanol amine compound and application thereof

ActiveCN103071534AEasy to makeGood dispersionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSubstance amountTriphenylphosphine

The invention provides catalyst for catalytically synthesizing an N-methyl ethanol amine compound and a preparation method thereof. The catalyst adopts a mesopore Al2O3 as a carrier; after modifying the carrier, alkali metal salt is dipped in organic solution of triphenylphosphine, and is dried to obtain the catalyst; and in the catalyst, the substance amount ratio of thetriphenylphosphine to an alkali metal element to an aluminum element is 1: (2.5-7.5): (4.5-9.3). The catalyst has the characteristics of simplicity in preparation, excellent dispersivity, large specific surface area, long service life and the like. The catalyst is applied in the reaction of N methyl ethanol amine organic amine (MMEA, DMEA), so that the conversion rate is high, and the selectivity is good.

Owner:NINGBO ZHETIE JIANGNING CHEM +1

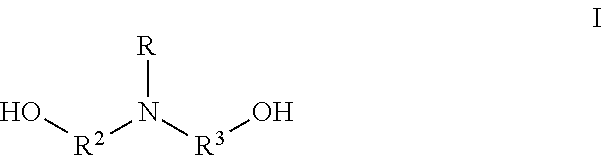

Polyether polyol providing good blow-gel balance for polyurethane products made therefrom

The present invention discloses a tertiary amine initiator and polymeric polyol compositions made therefrom useful for making polyurethane polymers, especially polyurethane foams. Said polyurethane polymer foams demonstrate a good balance of mechanical properties, physical properties and low emissions. The tertiary amine initiator is the reaction product of a dihydroxy tertiary amine and a polyhydroxy alcohol, such as the reaction product of N-methyl ethanolamine and glycerine.

Owner:DOW GLOBAL TECH LLC

Surface coating slurry for moisture-permeable waterproof fabric and its preparation process

ActiveCN103214682BSolve the weakness that it is easy to expand when exposed to waterGood moisture permeabilityFibre treatmentButanoneSlurry

The invention discloses a surface coating slurry used for moisture permeable waterproof fabrics and a preparation technology, the surface coating slurry comprises polyurethane resin, butanone, toluene, water and N-methyl ethanolamine; the preparation technology comprises the following steps: uniformly mixing butanone, water and polyurethane resin to form a main resin solution according to mass proportion of 66-68:3-5:29; placing a mixed liquid of butanone and toluene in the main resin solution to form a main resin mixed solution; mixing N-methyl ethanolamine and main resin mixed solution to form adjusted main resin mixed solution; uniformly mixing water and butanone according to mass proportion of 9:1 to form a solvent; mixing the solvent and the adjusted main resin mixed solution; passing the main resin mixed solution adjusted by the step 5 through a nylon net with 100-200 meshes for filtering to obtain the filtered main resin mixed solution; and standing the filtered main resin mixed solution for at least 2 hours for deaeration treatment. The coating fabrics formed by the surface coating slurry has uniform micropore, and is difficult to be expanded when contacting water.

Owner:KUNSHAN HUAYANG NEW MATERIAL

Manufacturing technology for wear-resisting prime coat material for breathable fabric

ActiveCN104727144ASolve the weakness that it is easy to expand when exposed to waterGood moisture permeabilityFibre treatmentManufacturing technologyMass ratio

The invention discloses a manufacturing technology for a wear-resisting prime coat material for a breathable fabric. The technology comprises the following steps: uniformly mixing butanone, water and polyurethane resin at the mass ratio of (66-68):(3-5):(29-31) to form a main resin solution; adding N-methyl ethanolamine as an accelerant into the main resin solution, wherein the mass ratio of the main resin solution to the accelerant is 100:(2.5-3.5); uniformly mixing water and butanone at the mass ratio of 9:1 to obtain a solvent, wherein the mass ratio of the solvent to a mixed main resin solution adjusted in step 4 is 100:(30-35); and standing a filtered mixed main resin solution for at least 2 hours, and performing defoaming treatment. According to the technology, the probability that the surface part, contacted with air, of liquid resin crusts easily and is turned from a liquid state into a solid state to become a dead colloid is avoided effectively, and the phenomenon that a great amount of adhesive tape abnormity is caused during the operation process to reduce the level of the fabric is avoided.

Owner:KUNSHAN HUAYANG NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com