Noise-reducing epoxy acrylic resin, noise-reducing emulsion and noise-reducing waterborne coating

A technology of epoxy acrylic and water-based coatings, applied in the direction of polyurea/polyurethane coatings, coatings, etc., to achieve the effect of improving slippery performance, filling concave vortices, and improving sound absorption and noise reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

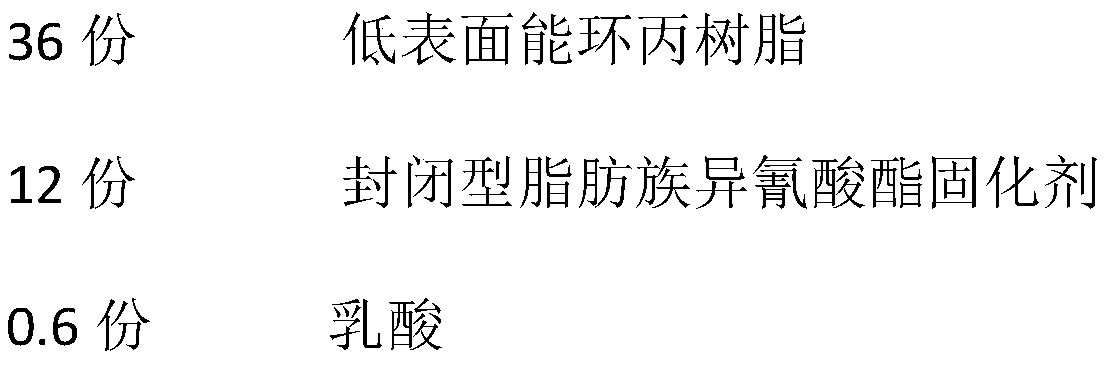

[0018] Embodiment 1 prepares low surface energy cyclopropane resin

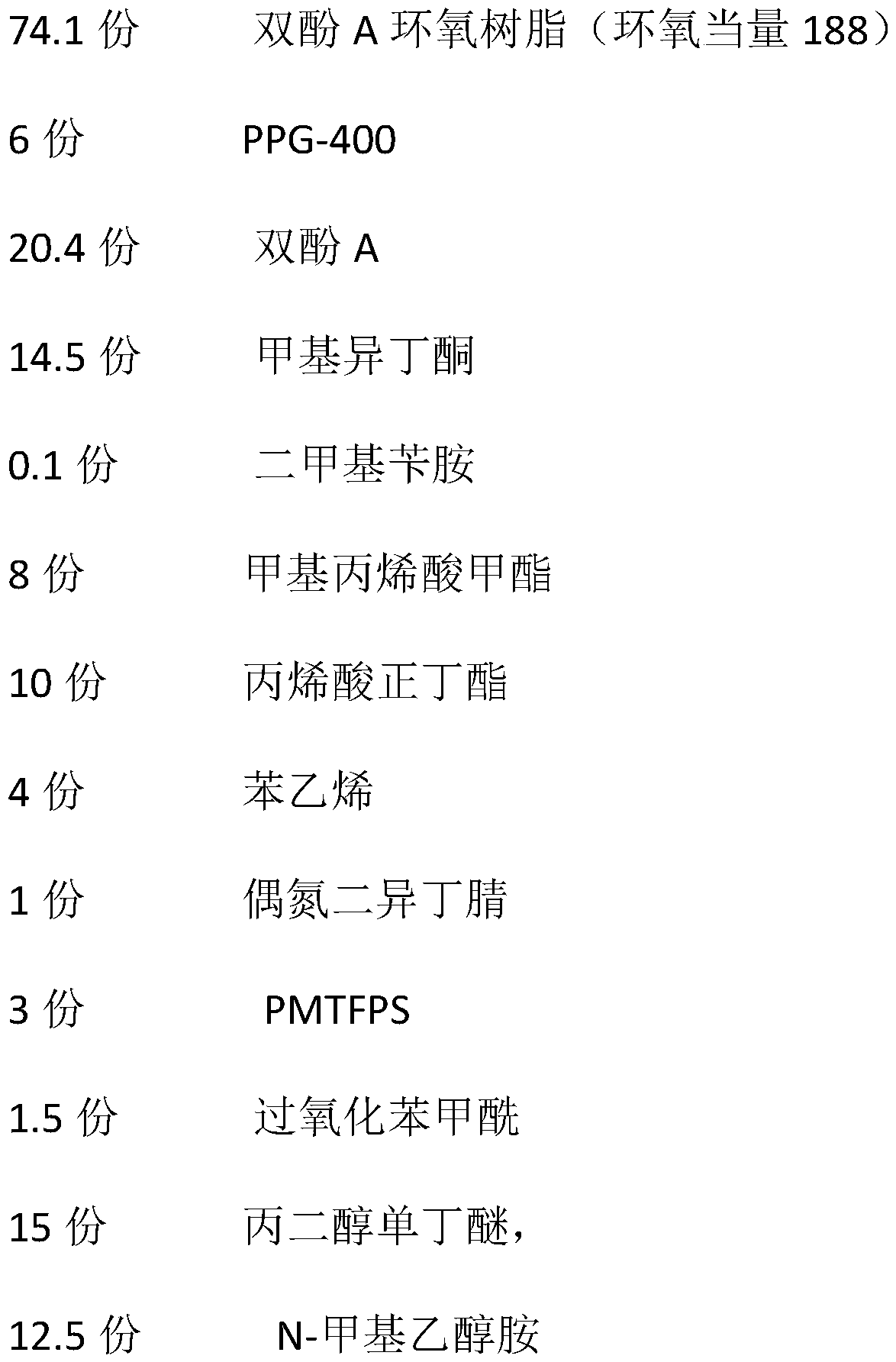

[0019]

[0020] In the flask with stirring, condenser and dropping funnel, add bisphenol A epoxy resin, PPG-400, bisphenol A and methyl isobutyl ketone with an epoxy equivalent of 188 according to the formula, and heat up to 100°C. Add dimethylbenzylamine, continue to heat up to 125°C and stir for 1.5 hours until the epoxy equivalent is 750±50, drop the temperature to 115°C and add the mixed solution (methyl methacrylate, n-butyl acrylate, styrene, azo Diisobutyronitrile, PMTFPS, benzoyl peroxide), after 3 hours of dropwise addition, add propylene glycol monobutyl ether after half an hour of heat preservation, cool down to 105°C, add N-methylethanolamine, and react at 115°C for 3 hours, A low surface energy cyclopropane resin is obtained.

Embodiment 2

[0021] Embodiment 2 prepares blocked aliphatic isocyanate curing agent:

[0022] 10 parts methyl isobutyl ketone

[0023] 35 MDIs

[0024] 25 parts ethylene glycol butyl ether

[0025] Add methyl isobutyl ketone and MDI into a reaction vessel with a stirrer and a condenser according to the formula amount, blow nitrogen, raise the temperature to 75°C, add ethylene glycol butyl ether dropwise, drop it in 1 hour, and keep it warm for 2 hours , the temperature is lowered to below 45°C and the material is discharged to obtain the blocked aliphatic isocyanate curing agent.

Embodiment 3

[0026] Embodiment 3 prepares organosilicon modified epoxy auxiliary agent

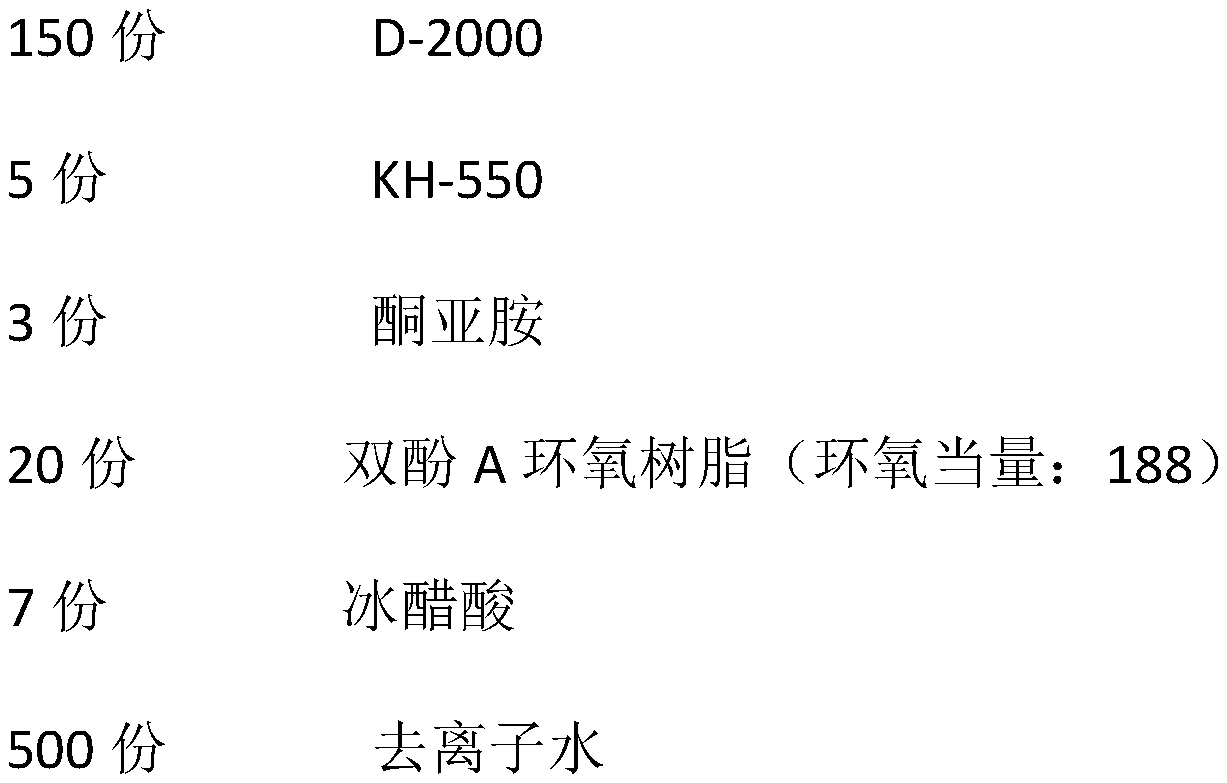

[0027]

[0028] Add D-2000, KH-550, and ketimine into the reaction vessel with a stirrer and condenser according to the formula amount, blow nitrogen, heat up to 130°C, add bisphenol A epoxy resin with an epoxy equivalent of 188, 130 Keep warm at ℃ for 30 minutes, cool down to below 95 ℃, add acetic acid aqueous solution, and neutralize at 80 ℃ for 30 minutes, pay attention to observe the state of additives, if the viscosity is extremely increased, add deionized water in the last step to dilute and reduce viscosity in time to obtain the silicone Modified epoxy additives.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com