Hydroxyl-terminated polyacrylate oligomer as well as preparation method and application thereof

A technology of hydroxyl-terminated polyacrylic acid and polyacrylates, which is applied in the preparation of carboxylates by oligomerization, organic chemistry, etc., and can solve problems such as adverse effects of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

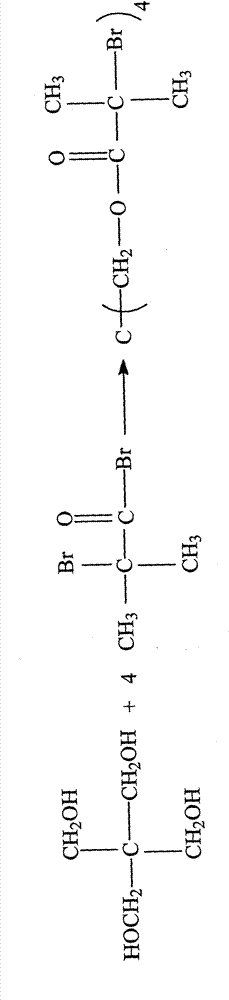

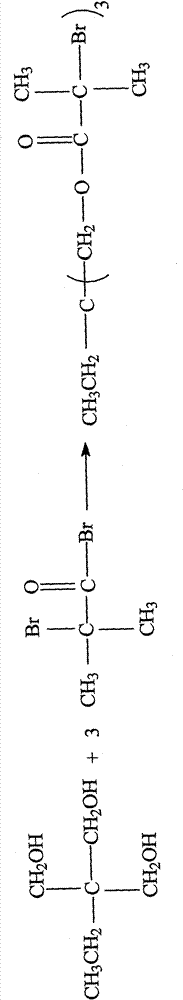

Method used

Image

Examples

Embodiment 1

[0044] Example 1: (Preparation of polybutyl acrylate with a molecular weight of 500)

[0045] Polymerization formula: initiator (ethyl α-bromoisobutyrate): monomer (butyl acrylate): catalyst: ligand = 1: 2.4: 0.048: 0.096 (molar ratio), and then add 25% of the system mass. Ethyl acetate was used as solvent.

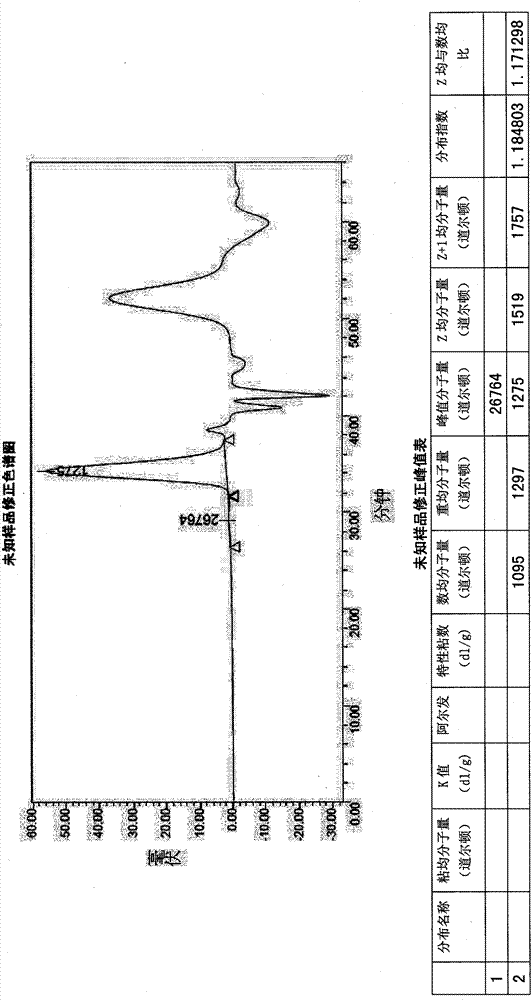

[0046] Polymerization step: add 128.94g (0.66mol) initiator ethyl α-bromoisobutyrate, 202.37g (1.58mol) monomer butyl acrylate, 4.59g (0.032mol) catalyst CuBr in a 500ml four-necked flask, 11.05g (0.064mol) ligand PMDETA, 86.74g solvent ethyl acetate, mix well. The system was evacuated and filled with nitrogen, and the reaction was stirred for 8 hours under an oil bath at 70°C. After the reaction is completed, after removing the catalyst and the solvent, a light yellow transparent and slightly viscous product can be obtained, the product mass is 304.4 g, and the yield is 91.9%. GPC test was performed on the product, and the number-average molecular weight of polybutyl ...

Embodiment 2

[0047] Embodiment 2: (the preparation of molecular weight 500 hydroxyl-terminated polybutyl acrylate)

[0048] Modified formula: polybutylacrylate:N-methylmonoethanolamine:triethylamine=1:25:5 (molar ratio). Modification step: add 19.63g (0.034mol) polybutyl acrylate in Example 1, 69.4g (0.925mol) N-methylmonoethanolamine, 19.2g (0.190mol) triethylamine into a 150ml four-necked flask, mix well . The system was evacuated and filled with nitrogen, and the reaction was stirred for 8 hours in an oil bath at 90°C. After the reaction, pickling was performed, and the oil layer was extracted after washing with anhydrous MgSO. 4 After drying, it was passed through a column, and finally the solvent was removed to obtain 6.7 g of a light yellow, viscous and transparent product. Yield 34%. GPC test was performed on the product, and the number-average molecular weight of the hydroxyl-terminated polybutylacrylate was Mn=642, and the molecular weight distribution PDI=1.09. The hydroxyl-...

Embodiment 3

[0049] Example 3: (Preparation of polybutyl acrylate with a molecular weight of 1000)

[0050] Polymerization formula: initiator (ethyl α-bromoisobutyrate): monomer (butyl acrylate): catalyst: ligand=1:7:0.07:0.014 (molar ratio), then add 25% of the system mass. Ethyl acetate was used as solvent.

[0051] Polymerization step: add 39.42g (0.20mol) initiator ethyl α-bromoisobutyrate, 179.91g (1.405mol) monomer butyl acrylate, 2.02g (0.014mol) catalyst CuBr in a 500ml four-necked flask, 4.83g (0.028mol) ligand PMDETA, 67g solvent ethyl acetate, mix well. The system was evacuated and filled with nitrogen, and the reaction was stirred for 8 hours under an oil bath at 70°C. After the reaction is completed, after removing the catalyst and the solvent, a light yellow transparent and slightly viscous product can be obtained, the product quality is 167.4 g, and the yield is 93%. The product was tested by GPC, and the number-average molecular weight of polybutyl acrylate was obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com