Slump retaining type concrete synergist and preparation method thereof

A concrete synergist and slump-preserving technology, which are applied in the field of slump-preserving concrete synergists and their preparation, can solve the problem that the synergist effect is unstable, the concrete strength is not significantly improved, and the slump loss is not significantly improved and other problems, to achieve the effects of low preparation cost, increased compactness, and promotion of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

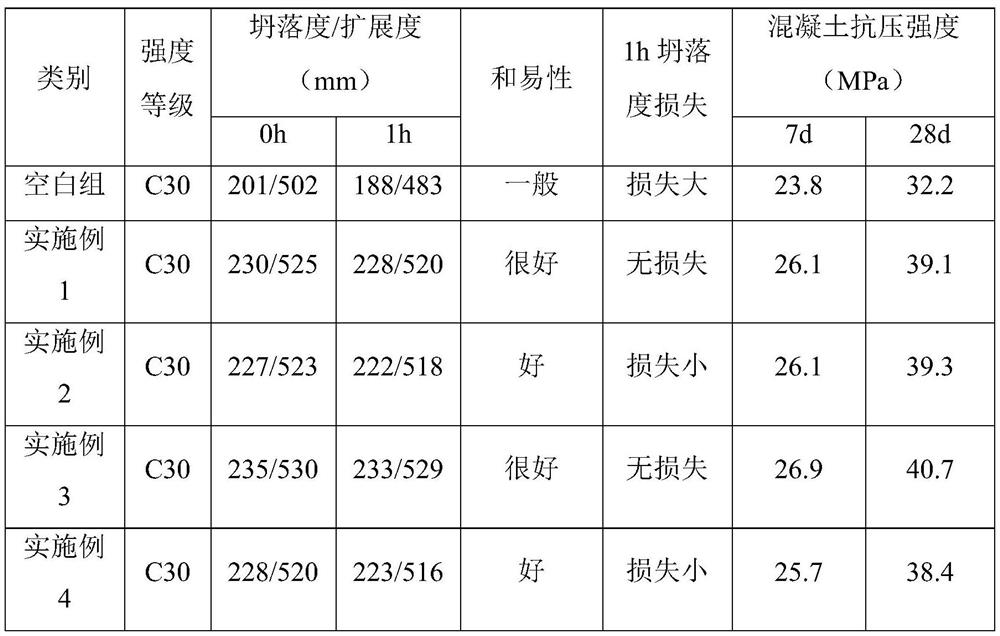

Examples

Embodiment 1

[0027] A preparation method of a slump-preserving concrete synergist is realized through the following steps:

[0028] 1) According to the percentage of the total weight of raw materials, the following raw materials were weighed: 20 parts of reinforcing agent, 8 parts of acetylpiperazine, 5 parts of alkanol acrylate copolymer, 5 parts of maleic anhydride, 8 parts of sodium pyrophosphate, N - 2 parts of sodium oleoyl-N-methyl taurate, the balance being water;

[0029] 2) Add the enhancer, acetylpiperazine, maleic anhydride and water into the stirring tank and stir for 25 minutes, then add the retarder and stir for 6 minutes, continue to add the alkanol acrylic acid copolymer under stirring until the materials are completely dissolved and uniform;

[0030] 3) Finally, add the lubricant, stir for 17 minutes and then let it stand to get the slump-preserving concrete synergist.

Embodiment 2

[0032] A preparation method of a slump-preserving concrete synergist is realized through the following steps:

[0033] 1) According to the percentage of the total weight of raw materials, the following raw materials were weighed: 12 parts of reinforcing agent, 15 parts of acetylpiperazine, 8 parts of alkanol acrylate copolymer, 8 parts of maleic anhydride, 4 parts of sodium pyrophosphate, N - 5 parts of sodium oleoyl-N-methyl taurate, the balance being water;

[0034] 2) Add the enhancer, acetylpiperazine, maleic anhydride and water into the stirring tank and stir for 28 minutes, then add the retarder and stir for 8 minutes, continue to add the alkanol acrylic acid copolymer under stirring until the materials are completely dissolved and uniform;

[0035] 3) Finally, add the lubricant, stir for 18 minutes and then let it stand to get the slump-preserving concrete synergist.

Embodiment 3

[0037] A preparation method of a slump-preserving concrete synergist is realized through the following steps:

[0038] 1) According to the percentage of the total weight of raw materials, weigh the following raw materials: 17 parts of reinforcing agent, 10 parts of methanesulfonylpiperazine, 10 parts of alkanol acrylate copolymer, 5 parts of maleic anhydride, 7 parts of sodium pyrophosphate , 3 parts of sodium N-oleoyl-N-methyl taurate, the balance being water;

[0039] 2) Add the enhancer, acetylpiperazine, maleic anhydride and water into the stirring tank and stir for 26 minutes, then add the retarder and stir for 6 minutes, continue to add the alkanol acrylic acid copolymer under stirring until the materials are completely dissolved and uniform;

[0040] 3) Finally, add the lubricant, stir for 20 minutes and then let it stand to get the slump-preserving concrete synergist.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com