Microalgae solid-phase attached growth culture method with water and nutrition supplied based on capillary power

A cultivation method and capillary power technology, applied in the field of production and harvest of microalgae, can solve problems such as inability to save, and achieve the effect of saving resources and energy, saving energy, saving water resources and nitrogen and phosphorus nutrient sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

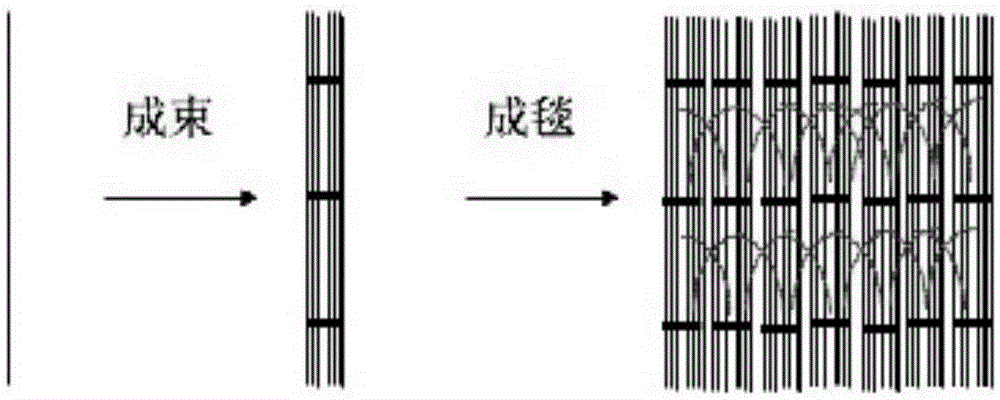

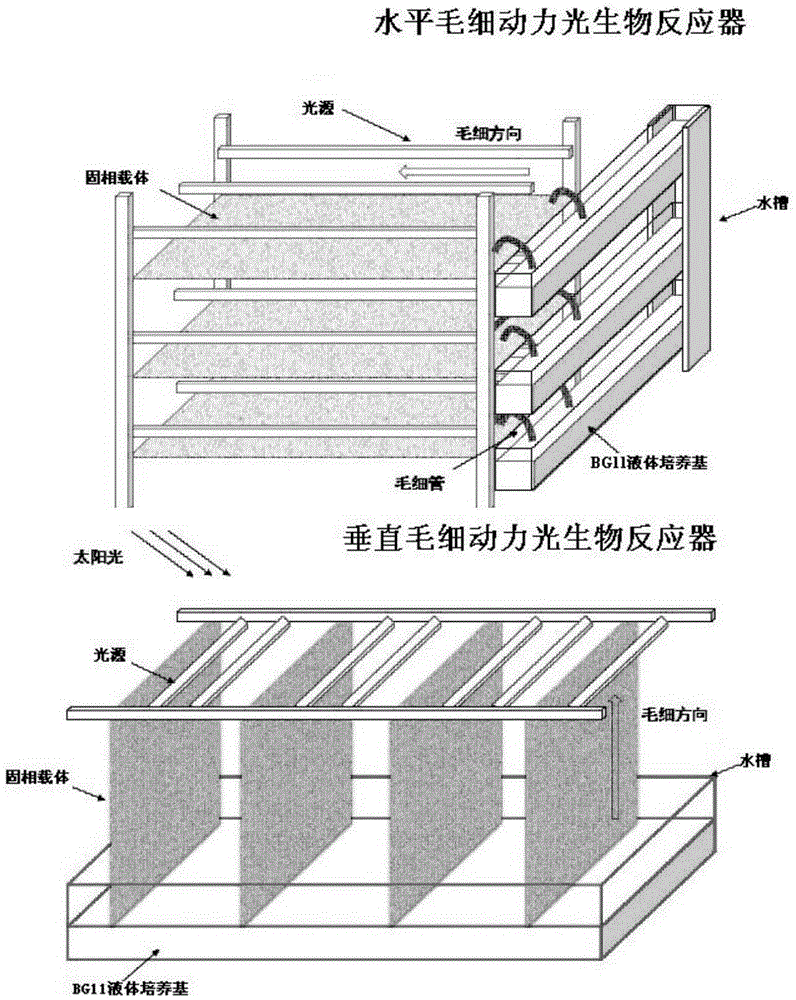

[0029] The preparation of solid phase carrier: by comparing the performance of multiple materials, select the microfiber (such as figure 1 shown), placed flat in a laboratory plexiglass algae box. Use 5cm polyester 300D superfine fiber as a capillary drainage tube, one end is connected to the BG11 liquid medium, and the other end is in contact with the solid phase carrier. For large-scale production and application, the large-area solid-phase carrier needs to be divided into several solid-phase carriers with appropriate areas, and each solid-phase carrier needs to be introduced into the BG11 liquid medium through a capillary drainage tube.

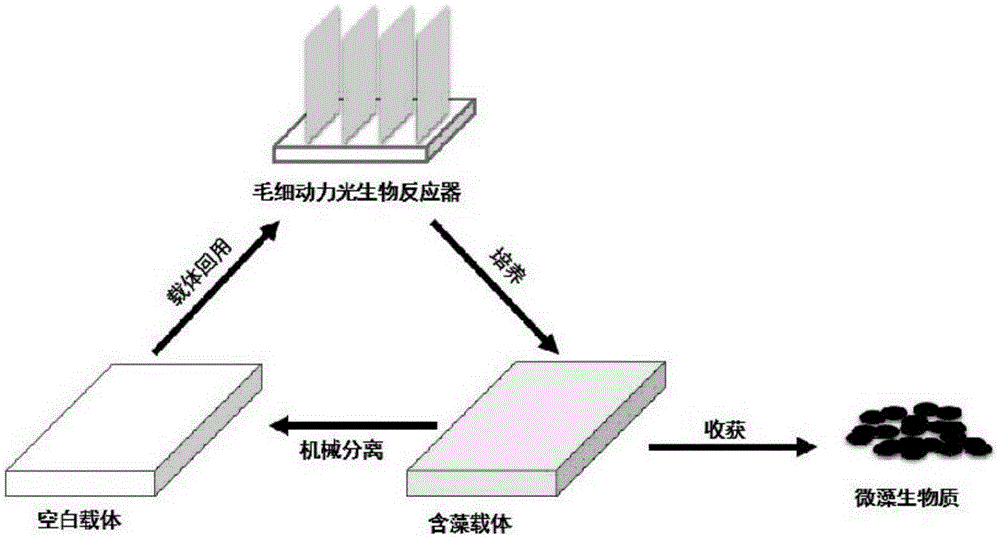

[0030] Cultivation stage: the solid phase carrier inoculated with microalgae is cultivated under light conditions to the harvestable stage. Harvesting time depends on the purpose of cultivation. If the oil in algae cells is extracted, it should be harvested in the middle of the stable period.

[0031] Harvesting stage: The carrier with ...

Embodiment 1

[0032] Embodiment 1: small-scale intermittent microalgae cultivation method

[0033] Evenly inoculate Scenedesmus.LX10.267g / m on a 3cm×5cm microfiber carrier 2 . Pour 30ml of the prepared BG11 liquid medium into each glass petri dish, use 5cm superfine fiber bundles to connect the solid phase carrier and BG11 liquid medium, after 10-20 minutes, the BG11 liquid medium can pass through capillary action Damp the entire algae blanket. Place the algae blanket and medium in an artificial climate incubator with a temperature of 25±2°C, a humidity of 30%, a light intensity of 1100 lux, and a light-to-dark ratio of 14:10. During the cultivation period, ensure that there is always remaining medium in the glass dish by intermittently adding medium. At the end of the cultivation, the water used for each algae blanket is between 215mL-235mL. In addition, in order to ensure that the algae blanket is evenly illuminated, the front and back of the algae blanket are reversed once a day. Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com