Oil layer protective agent for drilling fluid and production method thereof

A technology for oil layer protection and drilling fluid, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of incompatibility between working fluid fluid and formation fluid, high preparation cost of oil layer protection agent, poor compatibility of oil and gas layer rocks, etc. , to achieve the effect of low preparation cost, easy promotion and reduction of free water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

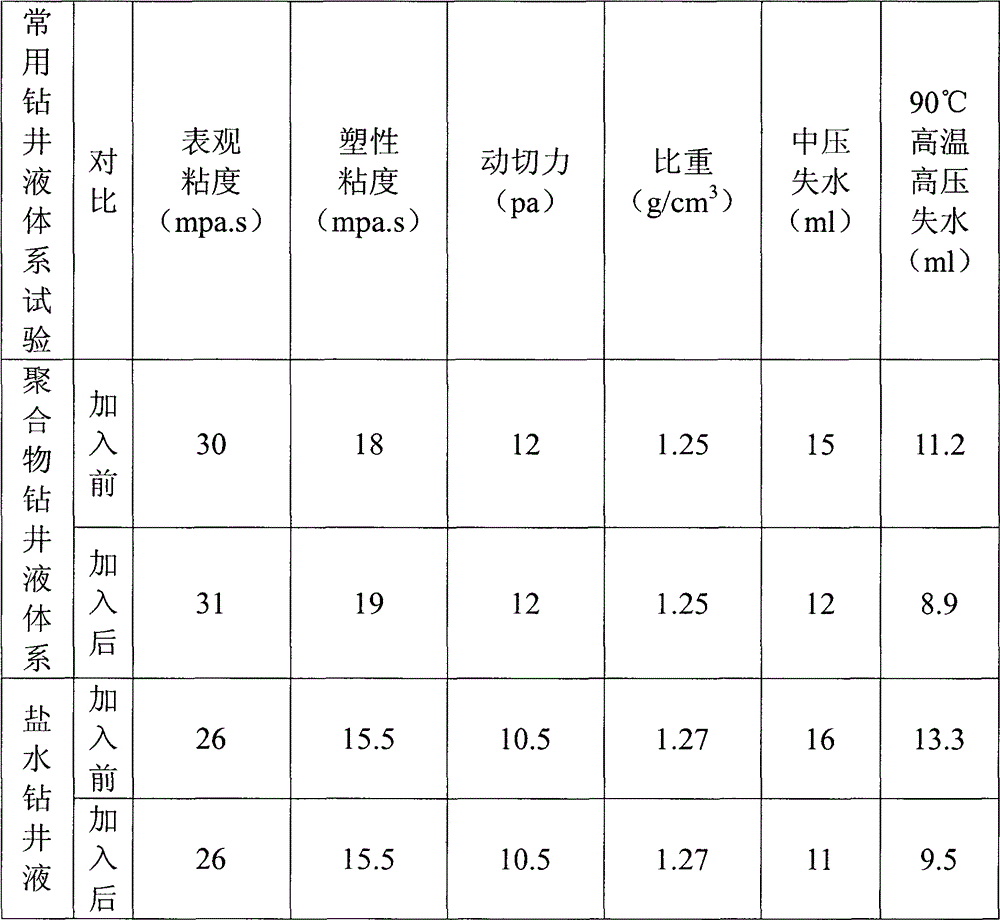

[0039] The oil layer protective agent for drilling fluid of the present invention comprises the following components by weight percentage:

[0040] Industrial water 27%, carboxymethyl cellulose 1.5%, white oil 60%, ammonium salt 5%, fine calcium carbonate 5%, defoamer 1.5%.

Embodiment 2

[0042] The oil layer protective agent for drilling fluid of the present invention comprises the following components by weight percentage:

[0043] Industrial water 35%, carboxymethyl cellulose 1%, white oil 53%, ammonium salt 5%, fine calcium carbonate 5%, defoamer 1%.

Embodiment 3

[0045] The oil layer protective agent for drilling fluid of the present invention comprises the following components by weight percentage:

[0046] Industrial water 27%, carboxymethyl cellulose 1.5%, white oil 50%, ammonium salt 10%, fine calcium carbonate 10%, defoamer 1.5%.

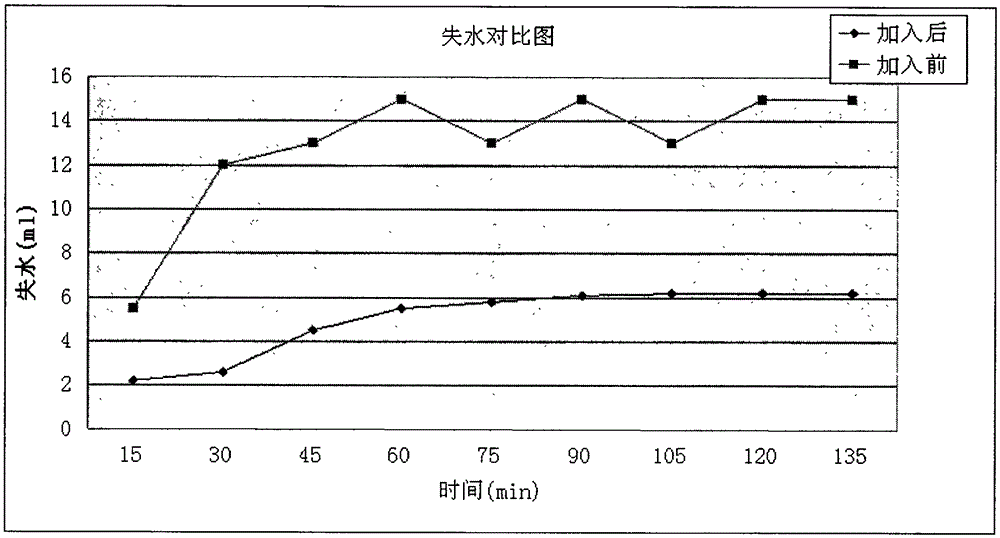

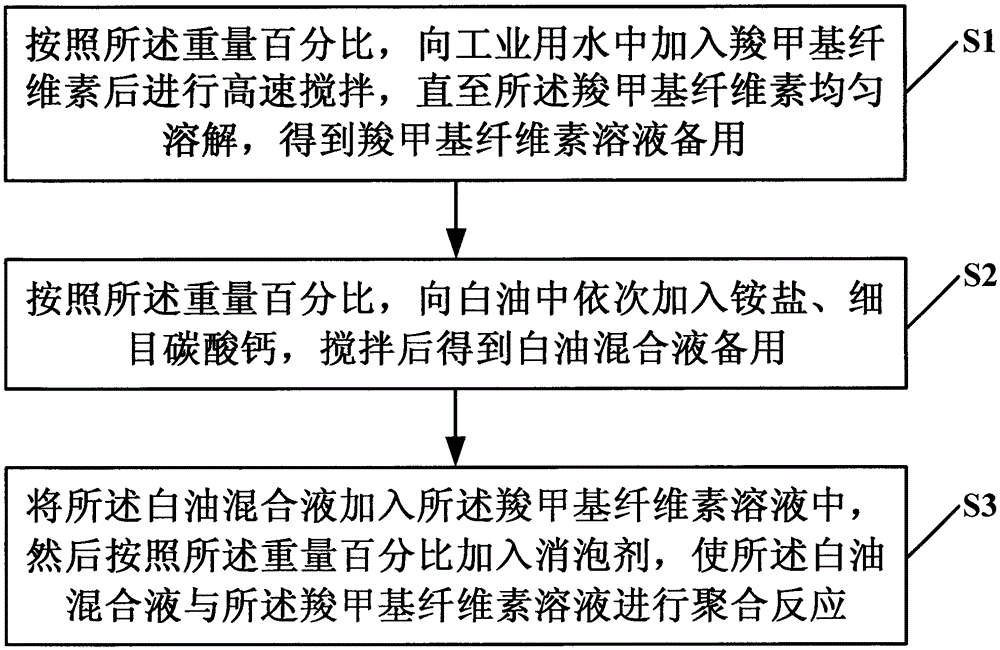

[0047] Such as figure 1 Shown, the present invention also provides a kind of method for producing above-mentioned oil layer protection agent for drilling fluid, comprises the steps:

[0048] 1. According to the weight percentage, add carboxymethyl cellulose to the industrial water and stir at a high speed until the carboxymethyl cellulose is uniformly dissolved to obtain a carboxymethyl cellulose solution for subsequent use;

[0049] 2. Add ammonium salt and fine-grained calcium carbonate to the white oil in sequence according to the weight percentage, and stir to obtain the white oil mixture for later use;

[0050] 3. Add the white oil mixture to the carboxymethyl cellulose solution, and then add a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com