Functionalized graphene, preparation method thereof and application of functionalized graphene in rubber base plate

A rubber backing plate and graphene technology, applied in the field of functionalized graphene and its preparation, can solve the problems of poor elasticity, short life, low strength, etc., and achieve the effects of anti-solvent extraction, excellent mechanical properties, and guaranteeing aging performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A functionalized graphene masterbatch, prepared from natural rubber latex, N,N'-di-sec-butyl-p-phenylenediamine and graphene oxide, the graphene oxide sheet has a diameter of 5-10 μm, a purity of 98%, and oxygen The content is 45%, and the preparation process is as follows:

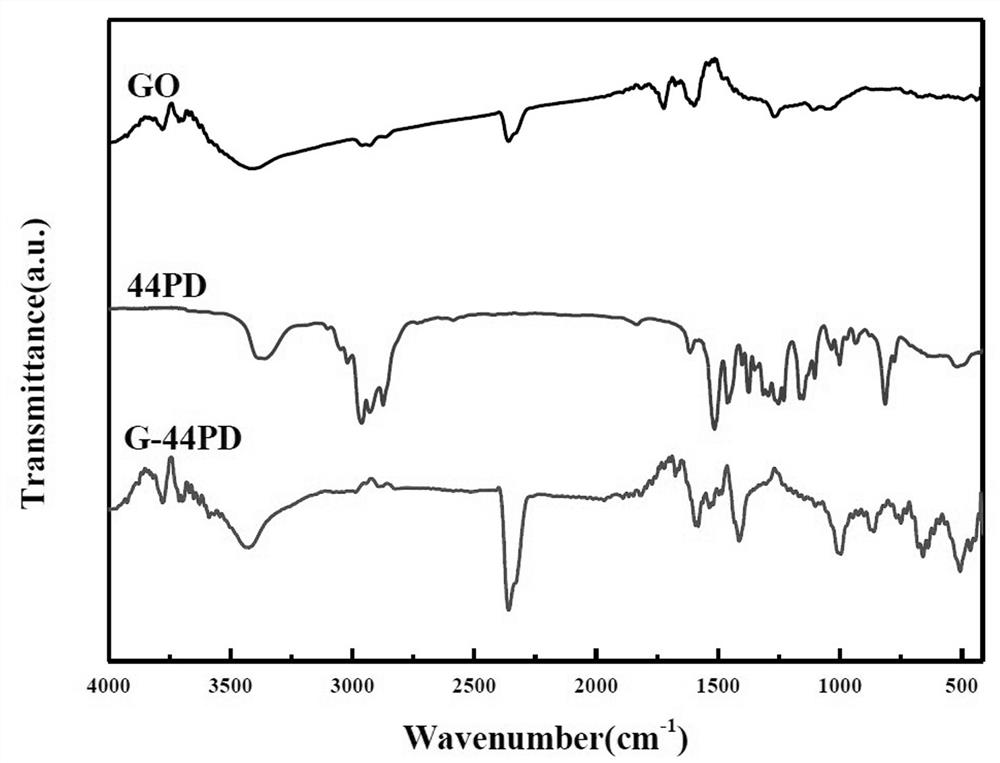

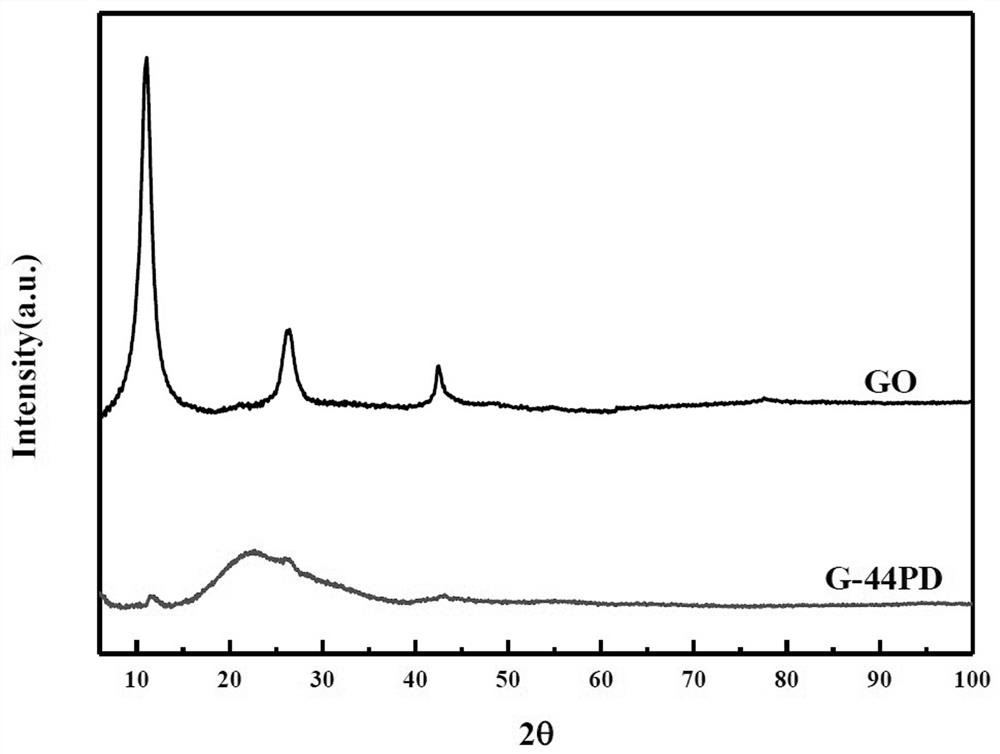

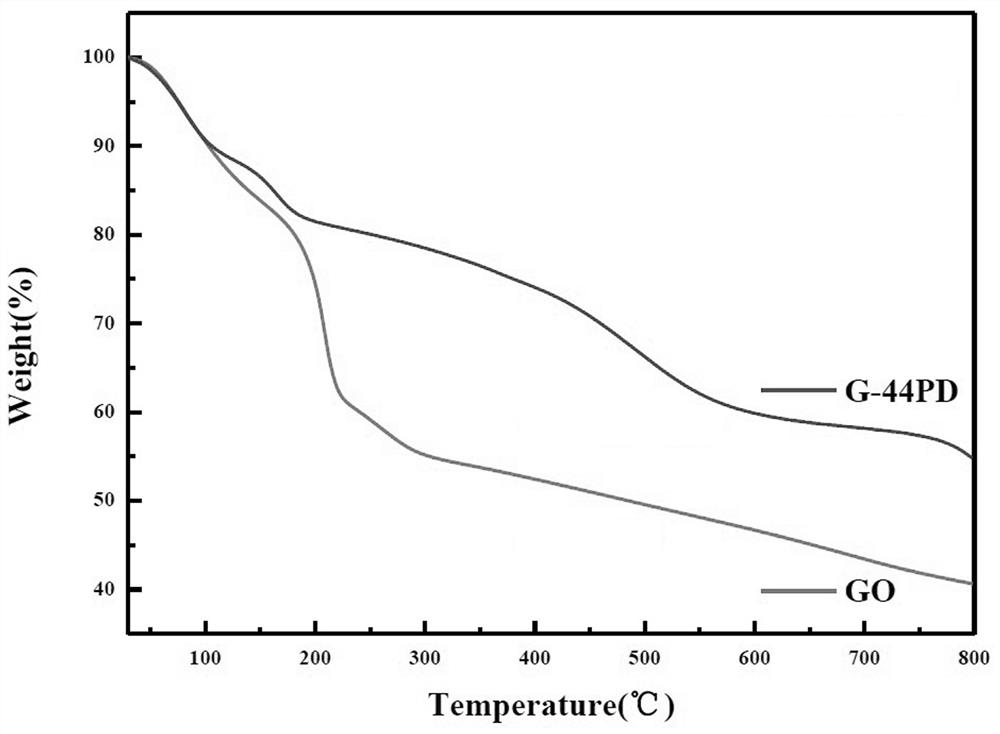

[0059] (1) Add N,N'-di-sec-butyl-p-phenylenediamine and graphene oxide at a weight ratio of 3:1 to a mixed system of water and ethanol at a ratio of 1:4, heat to 85°C, and react for 5 hours . After that, it was washed with ethanol to obtain functionalized graphene I.

[0060] (2) Sonicate 4 g of functionalized graphene I, 150 ml of deionized water and 50 ml of ethanol for 30 min to obtain a functionalized graphene dispersion. Stir the functionalized graphene dispersion with 35g of natural latex (solid content: 62%) for 2 hours to obtain a mixed latex, then pour the mixed latex into a calcium chloride-ethanol mixed solution to break the emulsion, wash three times with distilled water, and dry it t...

Embodiment 2

[0068] A functionalized graphene oxide masterbatch, made from natural rubber latex, N,N`-bis(1,3-dimethylbutyl)-p-phenylenediamine and graphene oxide, the graphene oxide sheet diameter 8-10μm, purity 98%, oxygen content 45%, the preparation process is as follows:

[0069] (1) Add N,N`-bis(1,3-dimethylbutyl)-p-phenylenediamine and graphene oxide with a weight ratio of 5:1 to the mixed system of water and ethanol with a ratio of 1:5 , heated to 95°C, and reacted for 8h. After that, it was washed with ethanol to obtain functionalized graphene II.

[0070] (2) Sonicate 3 g of functionalized graphene II, 200 ml of deionized water and 50 ml of ethanol for 50 min to obtain a functionalized graphene dispersion. Stir the graphene dispersion with 17.5g of natural latex (solid content: 62%) for 2 hours to obtain a mixed latex, then pour the mixed latex into a mixed solution of calcium chloride and ethanol to break the emulsion, wash it with distilled water three times, and dry it. Mas...

Embodiment 3

[0072] A functionalized graphene masterbatch, prepared from natural rubber latex, N,N`-bis(1,3-dimethylbutyl)-p-phenylenediamine and graphene oxide, the graphene oxide sheet diameter is 5 -10μm, purity 98%, oxygen content 45%, the preparation process is as follows:

[0073] (1) Add N,N`-bis(1,3-dimethylbutyl)-p-phenylenediamine and graphene oxide at a weight ratio of 3:1 to a mixed system of water and ethanol at a ratio of 1:4 , heated to 85 ° C, the reaction 5h. After that, it was washed with ethanol to obtain functionalized graphene III.

[0074] (2) Sonicate 4g of functionalized graphene III, 150ml of deionized water and 50ml of ethanol for 30min to obtain a functionalized graphene dispersion. Stir the functionalized graphene dispersion with 35g of natural latex (solid content: 62%) for 2 hours to obtain a mixed latex, then pour the mixed latex into a calcium chloride-ethanol mixed solution to break the emulsion, wash three times with distilled water, and dry it to prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com