Preparation method and dry material of green environment-friendly high slag erosion resistance dry material

A green, environmentally friendly, dry-type material technology, applied in the field of refractory materials for continuous casting, can solve the problems of waste of resources, erosion groove marks, deep slag, etc., and achieve the effect of improving the casting life, improving the quality of the casting billet, and reducing the cost of refractory materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

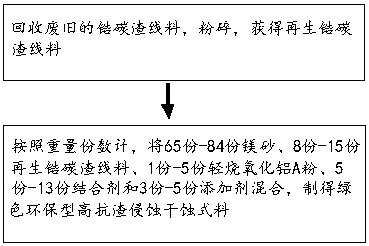

[0030] The invention provides a method for preparing a green and environment-friendly high-slag erosion-resistant dry material, which comprises the following steps:

[0031] S1) recycling the waste zirconium carbon slag strands, pulverizing them to obtain regenerated zirconium carbon slag strands;

[0032] S2) According to parts by weight, 65 parts-85 parts of magnesia, 8 parts-15 parts of regenerated zirconium carbon slag strands, 1 part-5 parts of light-burned alumina A powder, 5 parts-13 parts of binder and 3 parts Parts - 5 parts of additives are mixed to prepare a green and environmentally friendly dry material with high resistance to slag erosion.

[0033] Specifically, the recycling process of waste zirconium carbon slag strands:

[0034] Recycling of used submerged nozzles;

[0035] At the recycled waste submerged nozzle, according to the drawing of the submerged nozzle, determine the position of the zirconium carbon slag strand, cut the zirconium carbon slag strand,...

Embodiment 1

[0049] The preparation process of high anti-slag erosion dry material (1):

[0050] Recycling the waste submerged nozzle of a steel factory;

[0051]At the recycled waste immersion nozzle, according to the drawing of the immersion nozzle, determine the position of the zirconium carbon slag strand, use a brick cutter to cut the zirconium carbon slag strand, and use the fiber paper that sticks to the outer surface of the cut zirconium carbon slag strand , Steel slag and cold steel are treated, and the surface is pre-cleaned to obtain pretreated zirconium carbon slag strands;

[0052] The pretreated zirconium carbon slag strands are decarburized by high-temperature decarburization process to obtain decarburized zirconium carbon slag strands, that is, continuous heat preservation in an oxidizing atmosphere at 1100°C for 180 minutes;

[0053] After the decarburization slag strands are cooled, use a file to clean up the debris on the surface of the slag strands, and put them in a c...

Embodiment 2

[0059] The preparation process of high anti-slag erosion dry material (2):

[0060] Recycling the waste submerged nozzle of a steel factory;

[0061] At the recycled waste immersion nozzle, according to the drawing of the immersion nozzle, determine the position of the zirconium carbon slag strand, use a brick cutter to cut the zirconium carbon slag strand, and use the fiber paper that sticks to the outer surface of the cut zirconium carbon slag strand , Steel slag and cold steel are treated, and the surface is pre-cleaned to obtain pretreated zirconium carbon slag strands;

[0062] The pretreated zirconium carbon slag strands are decarburized by high-temperature decarburization process to obtain decarburized zirconium carbon slag strands, that is, continuous heat preservation in an oxidizing atmosphere at 1100°C for 180 minutes;

[0063] After the decarburization slag strands are cooled, use a file to clean up the debris on the surface of the slag strands, and put them in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com