Recyclable and degradable release material and preparation method thereof

A release material and base material technology, applied in the field of recyclable and degradable release material and its preparation, can solve the problem of unsuitable release silicon coating treatment, unsuitable high temperature release silicon coating, low transmittance of optical parameters And other problems, to achieve excellent tensile strength and barrier properties, low price, superior optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

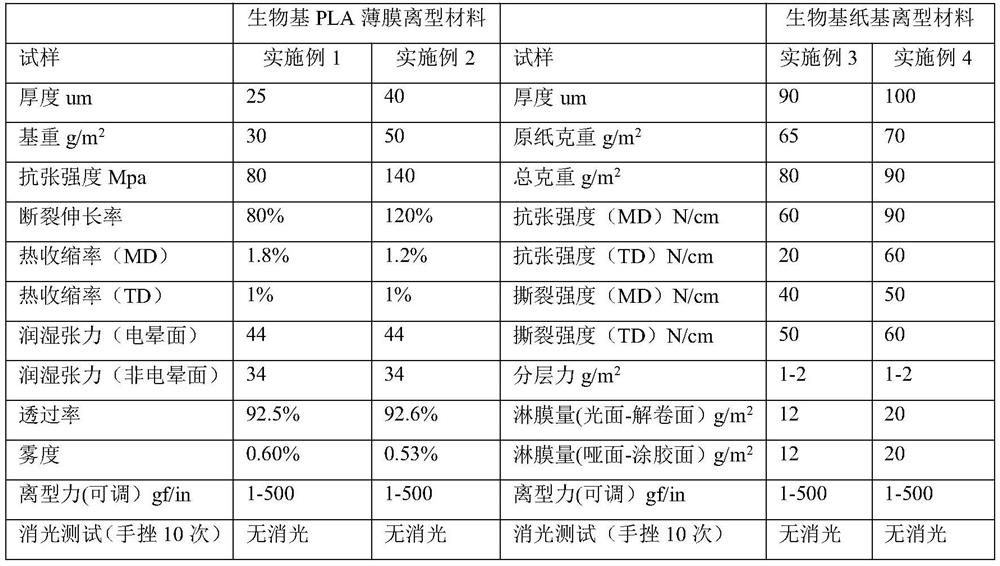

Examples

Embodiment 1

[0033] A recyclable and degradable release material and a preparation method thereof, comprising the following steps:

[0034] Polylactic acid resin (PLA) was dried at 80° C. for 5 h under vacuum conditions, and then 70 mass parts of polylactic acid resin, 15 mass parts of polybutylene carbonate, 5 mass parts of Irganox 1010 (Swiss Ciba Company), nano-silica Mix 3 parts by mass and 7 parts by mass of nano-titanium dioxide at a temperature of 170°C for 3 minutes, put the mixed block into a twin-screw extruder for processing, and then stretch it longitudinally and transversely to obtain a biaxially stretched BOPLA film , the melting temperature of the die head of the main extruder is 220°C; when stretching longitudinally first, the temperature in the preheating zone is 40°C, the temperature in the stretching zone is 60°C, the stretching ratio in the longitudinal direction is 2.5 times, and cooled to 35°C; then when stretching in the transverse direction , the temperature in the ...

Embodiment 2

[0036] A recyclable and degradable release material and a preparation method thereof, comprising the following steps:

[0037]Polylactic acid resin (PLA) was dried under vacuum at 80°C for 4h, then 75 parts by mass of polylactic acid resin, 10 parts by mass of polybutylene carbonate, 5 parts by mass of gafos 168 (Ciba, Switzerland), 10 parts by mass of nano-titanium dioxide Knead each part at a temperature of 170°C for 3 minutes, put the kneaded block into a twin-screw extruder for processing, and then stretch it longitudinally and transversely to obtain a biaxially stretched BOPLA film. The die head of the main extruder The melting temperature is 230°C; when stretching longitudinally first, the temperature in the preheating zone is 75°C, the temperature in the stretching zone is 80°C, the longitudinal stretching ratio is 3.5 times, and cooled to 35°C; then when stretching transversely, the temperature in the preheating zone is 120°C , the temperature in the stretching zone is...

Embodiment 3

[0039] A recyclable and degradable release material and a preparation method thereof, comprising the following steps:

[0040] The parts by mass of each component are 50 parts of tapioca starch, 10 parts of starch modifier, 5 parts of wetting agent, 15 parts of reinforcing agent, and 20 parts of polyvinyl alcohol; the starch modifier is degradable polycaprolactone, wetting agent It is PCL-based polyurethane prepolymer (PCLPU), and the reinforcing agent is aldehyde-based cellulose; gelatinized starch glue is formed by adding the components in proportion, stirring and mixing, then kneading with paper powder, and finally drying and granulating; 75 parts of polylactic acid resin, 15 parts of polybutylene carbonate, 5 parts of DLTP (German Albemarle), 5 parts of nano-alumina, the polylactic acid resin was vacuum-dried at 80 °C for 5 hours, and then the dried polylactic acid resin was mixed with poly Butylene carbonate and DLTP (German Albemarle) were melted and mixed at a temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com