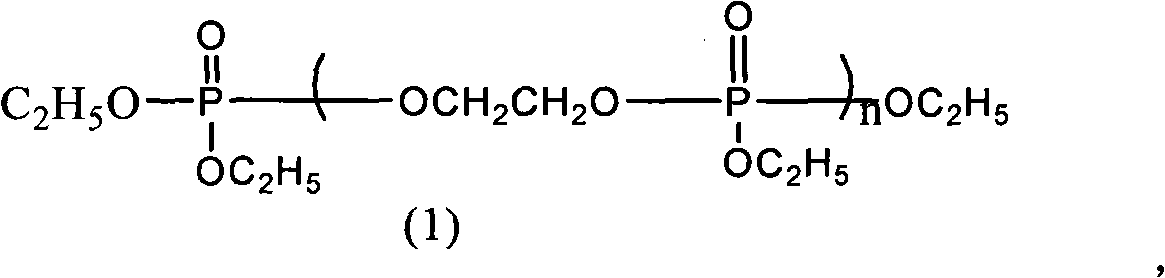

Polymer type phosphor-containing fire retardant, preparation method and application thereof

A flame retardant and polymer technology, applied in the field of polymer-type phosphorus-containing flame retardants and their preparation, can solve problems such as application limitations, and achieve the effects of stable product quality, superior flame retardant performance and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

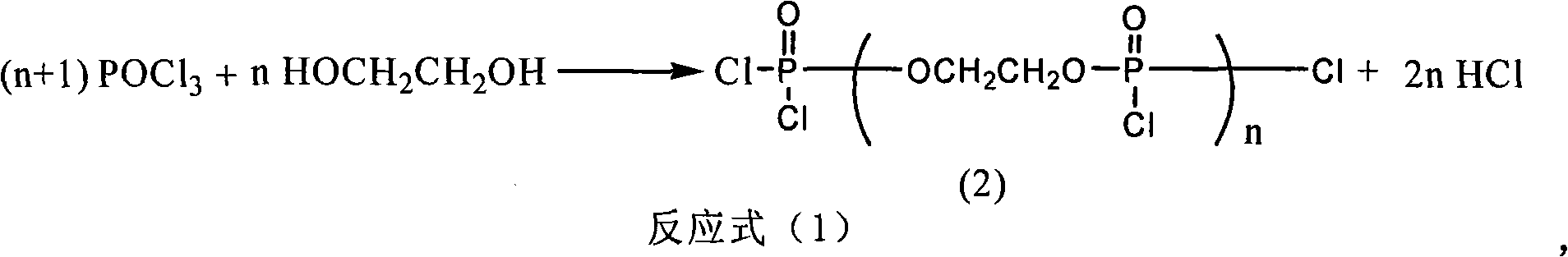

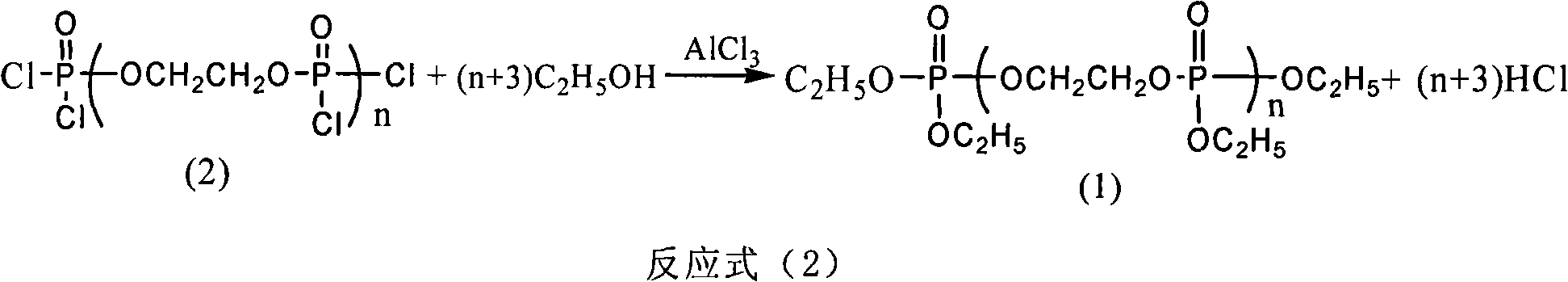

Method used

Image

Examples

Embodiment 1

[0031] (1) Use a vacuum pump to pump 767.5Kg of phosphorus oxychloride into the No. 1 reaction kettle, cool down to 10-15°C, and feed nitrogen into the kettle with a flow rate of 2m 3 / h, protect against oxidation, and slowly add 62Kg of ethylene glycol dropwise, dropwise for 8h, after the dropwise addition is completed, the temperature is raised to 18°C, and the material is stirred for 1h; the nitrogen gas is stopped, and the excess POCl 3 Distilled at -0.1MPa, 55°C under reduced pressure, after the distillation is completed, the temperature is lowered, and the discharge is passed into the No. 2 reaction kettle;

[0032] (2) Add catalyst AlCl to No. 2 reactor 3 Stir 533.4g for 0.5h, control the reaction temperature at 10-13°C with ice-salt water, add 184Kg of absolute ethanol dropwise, the dropwise addition time is 6h, after the dropwise addition, the temperature is raised to about 25°C, and the reaction is kept for 4h; the catalyst is removed by low-pressure suction filtrati...

Embodiment 2

[0034] In this example, according to the preparation process of Example 1, through multiple experiments, the molar ratio of raw materials, the amount of catalyst used, and the reaction temperature were respectively changed to obtain the optimal process.

[0035] 2.1 Molar ratio of raw materials in the first step reaction

[0036] Change the ratio of phosphorus oxychloride and ethylene glycol in the first step reaction (as table 1), other conditions carry out the first step reaction with embodiment 1, and wherein temperature refers to the temperature of dripping ethylene glycol.

[0037] Table 1

[0038]

Phosphorus oxychloride

Ethylene glycol

temperature

Group 1

2

1

10~15℃

Group 2

3

1

10~15℃

Group 3

5

1

10~15℃

Group 4

7

1

10~15℃

Group 5

8

1

10~15℃

[0039] After analysis, the polymerization degree of the first group is 10-15, the polymerizat...

Embodiment 3

[0058]The flame retardant PNX of the present invention and the phosphorus-halogen flame retardant T 101 (Tetrakis(β-chloroethyl)-1,2-ethylene bisphosphoric acid) is added in flexible polyurethane foam plastics for automobiles, the preparation process is a conventional process, and the respective formulas and properties are shown in Table 5 and Table 6.

[0059] Table 5.T 101 Formulation and Properties of Flame Retardant Flexible Polyurethane Foam

[0060] formula

[0061] Table 6. Formulation and performance of PNX flame-retardant flexible polyurethane foam

[0062] formula

[0063] formula

[0064] It can be seen from Table 5 and Table 6 that PNX reaches T 101 Adding 40% of the amount can achieve the same flame retardant effect, and its oxygen index is slightly higher than that of T101 flame retardant flexible polyurethane foam, and PNX flame retardant flexible polyurethane foam does not produce toxic smoke in the combustion test , and the T10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com