A kind of hydroxypiperazine concrete glue reducer and preparation method thereof

A kind of concrete-like, hydroxypiperazine technology, applied in the field of hydroxypiperazine-based concrete glue reducer and its preparation, can solve the problems of poor performance of the glue reducer, influence on the anti-freezing ability of concrete, and limitation of the use range of the glue reducer, etc. Ease of operation, improved frost resistance, and the effect of increasing hydration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

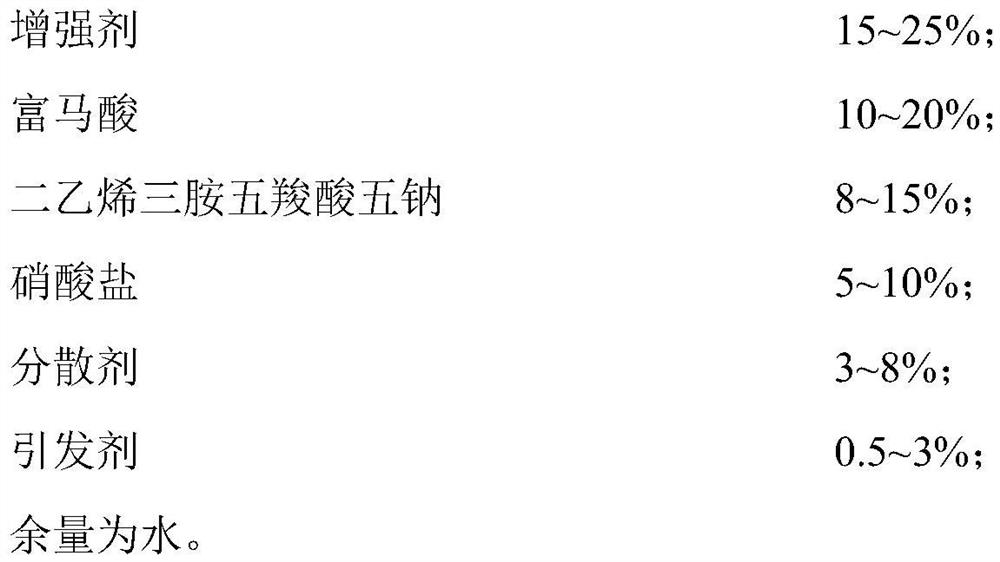

[0031] A hydroxypiperazine type concrete glue reducer and preparation method thereof, comprising the following raw materials by weight:

[0032]

[0033] The preparation method of a hydroxypiperazine concrete glue reducer according to the present invention is realized by the following steps:

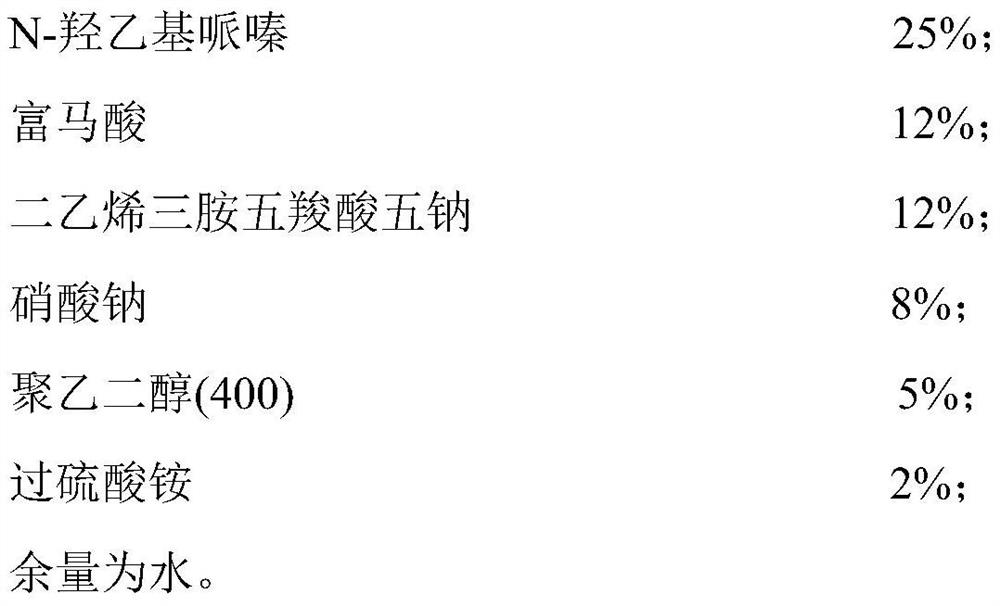

[0034] 1) N-Hydroxyethylpiperazine, pentasodium diethylenetriaminepentacarboxylate and sodium nitrate are added to the condensation reaction tank, add a certain amount of water to open stirring and gradually heat up, and be warming up to 80 °C after the raw materials are dissolved. ℃ and constant, holding the reaction for 1.2h;

[0035] 2) then add fumaric acid and polyethylene glycol (400) to the reaction tank, after stirring, start to drip the ammonium persulfate solution whose mass percentage concentration is 7% in the solution system, and the temperature is controlled at 85 ℃, control the dripping speed, ensure that the dripping time is 2h, and continue the constant temperature r...

Embodiment 2

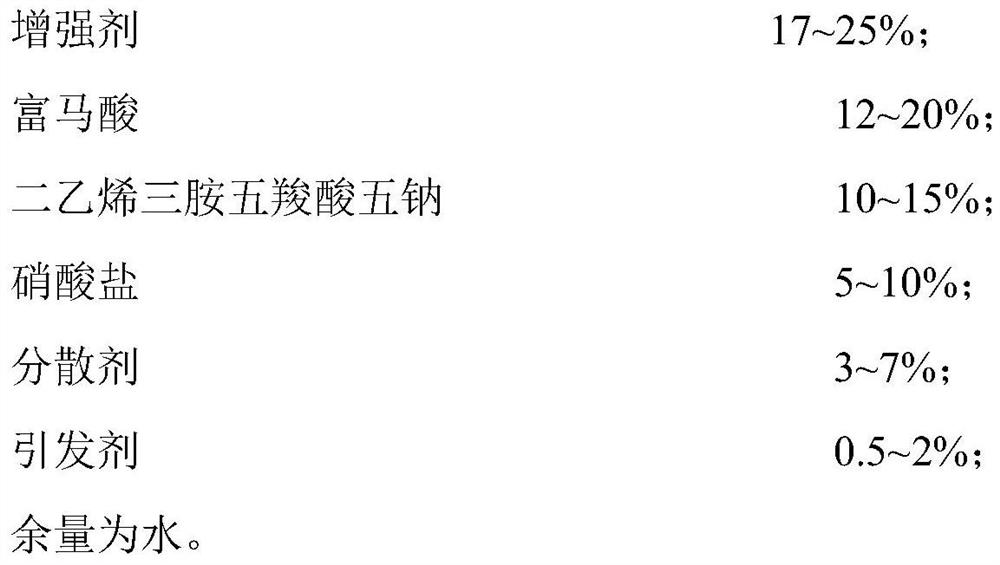

[0038] A hydroxypiperazine type concrete glue reducer and preparation method thereof, comprising the following raw materials by weight:

[0039]

[0040] The preparation method of a hydroxypiperazine concrete glue reducer according to the present invention is realized by the following steps:

[0041] 1) N,N'-bis(2-hydroxyethyl)piperazine, pentasodium diethylenetriaminepentacarboxylate, sodium nitrate are added to the condensation reaction tank, add a certain amount of water to open stirring and gradually heat up, After the raw materials are dissolved, the temperature is raised to 85 °C and kept constant, and the reaction is kept for 1 h;

[0042] 2) then add fumaric acid and polyethylene glycol (400) to the reaction tank, after stirring, start to drip the ammonium persulfate solution whose mass percentage concentration is 5% in the solution system, and the temperature is controlled at 85 ℃, control the dripping speed, ensure that the dripping time is 1.8h, and continue the...

Embodiment 3

[0045] A hydroxypiperazine type concrete glue reducer and preparation method thereof, comprising the following raw materials by weight:

[0046]

[0047] The preparation method of a hydroxypiperazine concrete glue reducer according to the present invention is realized by the following steps:

[0048] 1) N,N'-bis(2-hydroxypropyl)piperazine, pentasodium diethylenetriaminepentacarboxylate, potassium nitrate are added to the condensation reaction tank, add a certain amount of water to open stirring and gradually heat up, After the raw materials are dissolved, the temperature is raised to 90°C and kept constant, and the reaction is kept for 1.2h;

[0049]2) then add fumaric acid and polyethylene glycol (800) to the reaction tank, after stirring, start to drip the ammonium persulfate solution whose mass percentage concentration is 6% in the solution system, and the temperature is controlled at 90 ℃, control the dripping speed, ensure that the dripping time is 2h, and continue th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com