Polycarboxylic acid water reducing agent using diallyl polyethylene glycol (DAPEG) as raw material and preparation method thereof

A technology of polyethylene glycol ether and bisallyl, which is applied in the field of polycarboxylate water reducer, can solve the problems of no patent report, etc., and achieve improved water reduction effect, good slump retention, and good water reduction effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

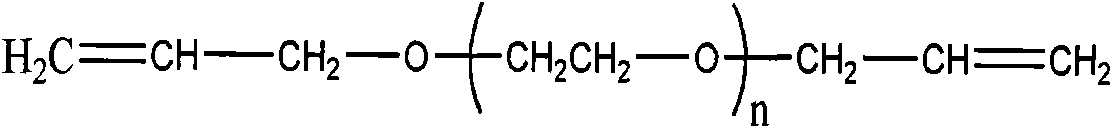

[0026] (1) Preparation of Diallyl Polyethylene Glycol Ether (DAPEG)

[0027] Add 200g polyethylene glycol (PEG200), 7g potassium hydroxide, 7g tetrabutylammonium bromide (TBAB) and appropriate amount of tetrahydrofuran in the reaction still equipped with stirrer, condensing device, drying device, nitrogen protection, then slowly Drop 150 g of allyl chloride and react at 40°C for 2 hours. After the reaction, remove the solvent and unreacted allyl chloride under reduced pressure to obtain the crude product. The crude product was dissolved in a mixed solvent of ethyl acetate and butyl acetate, and washed three times with saturated sodium chloride solution. Then dry and distill off the solvent under reduced pressure to obtain bisallyl polyethylene glycol ether (DAPEG300).

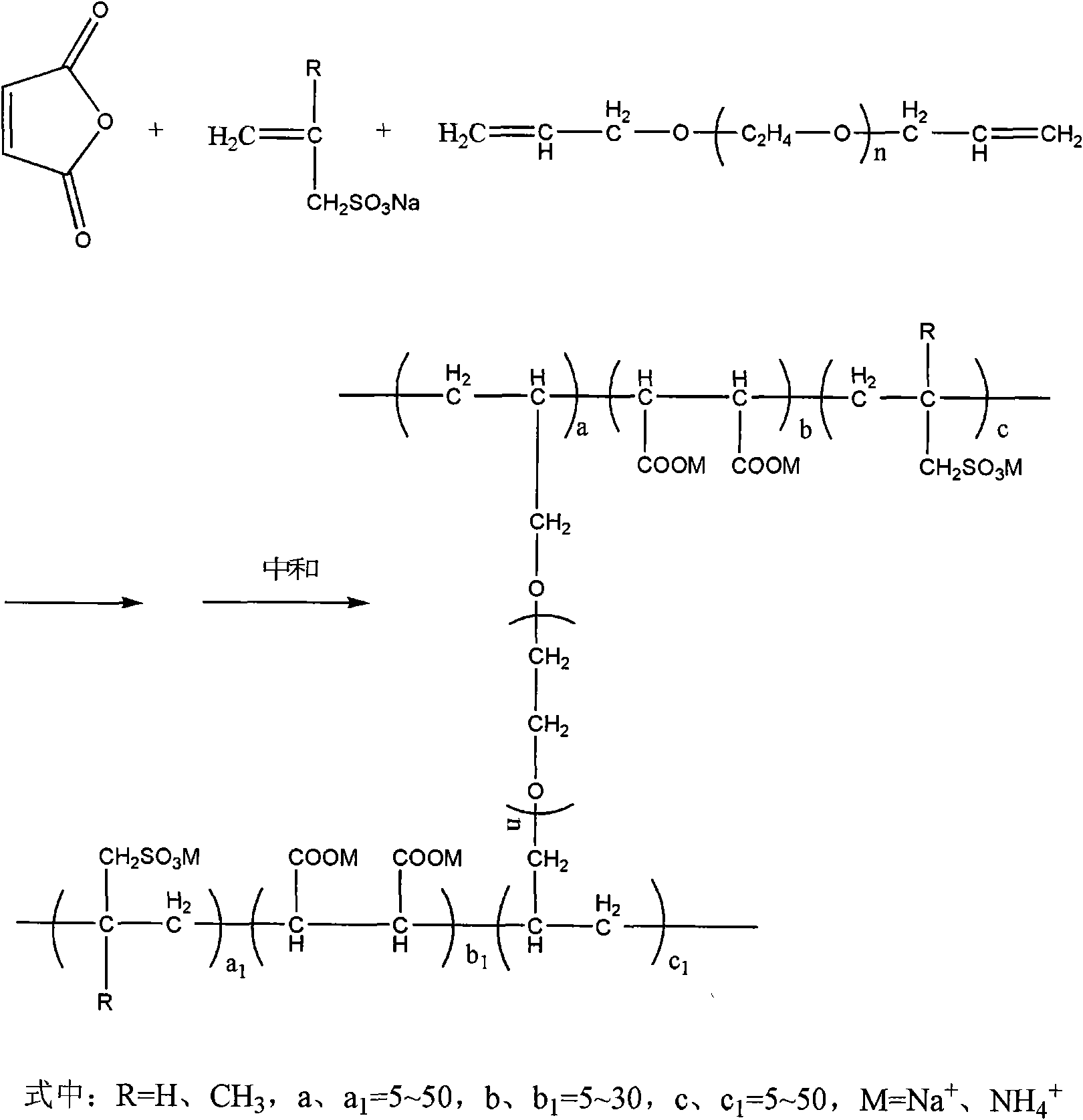

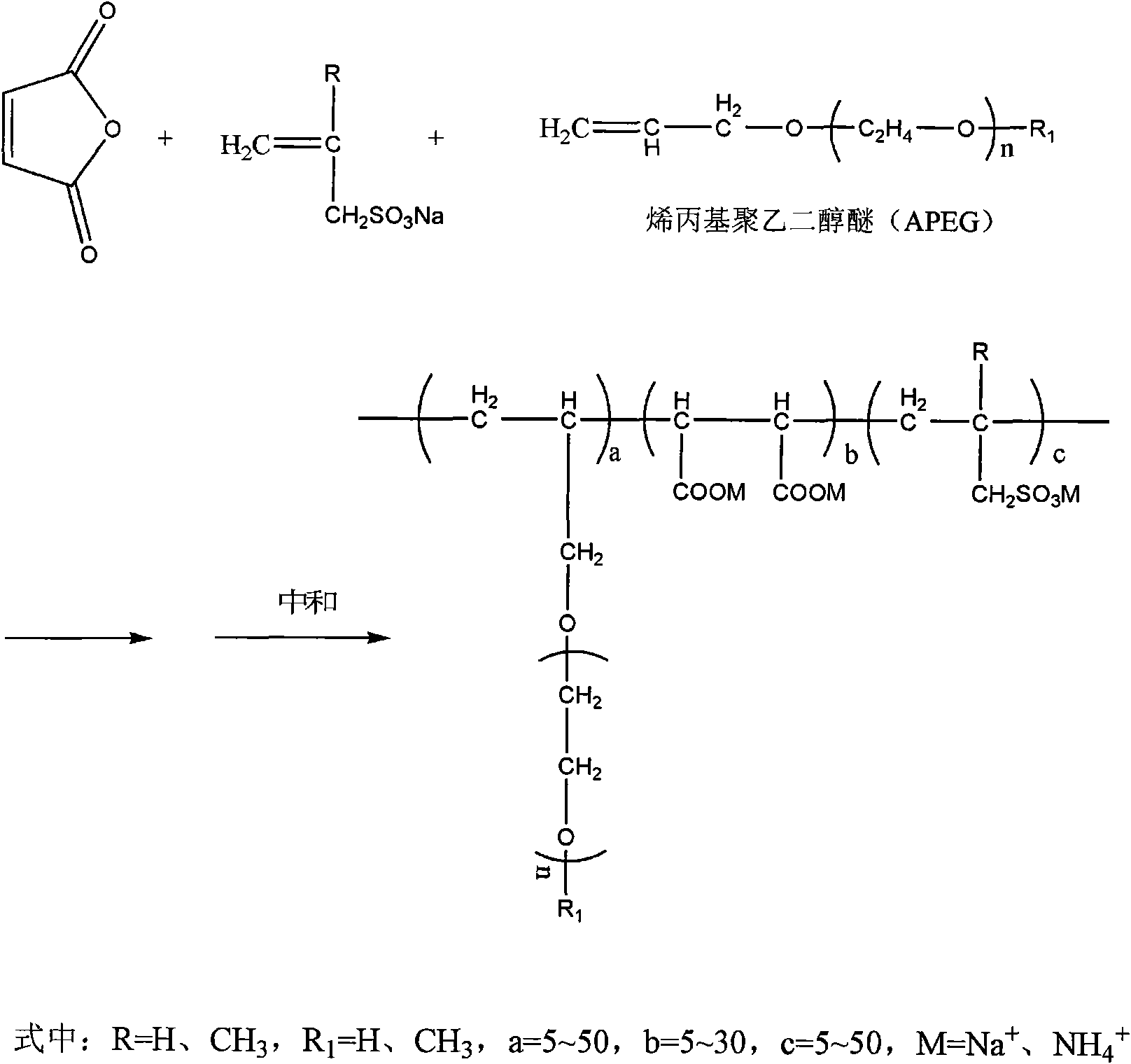

[0028] (2) Preparation of a new type of polycarboxylate water reducer using diallyl polyethylene glycol ether (DAPEG) as raw material

[0029] Add 300g Diallyl Polyethylene Glycol Ether (DAPEG300), 200g Malei...

Embodiment 2

[0031] (1) Preparation of Diallyl Polyethylene Glycol Ether (DAPEG)

[0032] Add 300g polyethylene glycol (PEG300), 10g potassium hydroxide, 20g tetrabutylammonium bromide (TBAB) and appropriate amount of tetrahydrofuran in the reactor equipped with stirrer, condensing device and drying device, nitrogen protection, and then slowly Drop 150 g of allyl chloride and react at 40°C for 3 hours. After the reaction, remove the solvent and unreacted allyl chloride under reduced pressure to obtain the crude product. The crude product was dissolved in a mixed solvent of ethyl acetate and butyl acetate, and washed three times with saturated sodium chloride solution. Then dry and distill off the solvent under reduced pressure to obtain bisallyl polyethylene glycol ether (DAPEG400).

[0033] (2) Preparation of a new type of polycarboxylate water reducer using diallyl polyethylene glycol ether (DAPEG) as raw material

[0034] 400g Diallyl Polyethylene Glycol Ether (DAPEG400), 200g Maleic An...

Embodiment 3

[0036] (1) Preparation of Diallyl Polyethylene Glycol Ether (DAPEG)

[0037] Add 400g polyethylene glycol (PEG400), 8g potassium hydroxide, 12g tetrabutylammonium bromide (TBAB) and appropriate amount of tetrahydrofuran in the reactor that is equipped with stirrer, condensing device, drying device, logical nitrogen protection, then slowly Drop 160 g of allyl chloride, react at 50°C for 3 hours, remove the solvent and unreacted allyl chloride under reduced pressure after the reaction, and obtain the crude product. The crude product was dissolved in a mixed solvent of ethyl acetate and butyl acetate, and washed three times with saturated sodium chloride solution. Then dry and distill off the solvent under reduced pressure to obtain bisallyl polyethylene glycol ether (DAPEG500).

[0038] (2) Preparation of a new type of polycarboxylate water reducer using diallyl polyethylene glycol ether (DAPEG) as raw material

[0039] 500g Diallyl Polyethylene Glycol Ether (DAPEG500), 200g M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com