Production method of ready-mix pumped heavy concrete

A production method and technology for heavy concrete, which are applied in chemical instruments and methods, clay preparation devices, cement mixing devices, etc., can solve the problems of increasing labor costs and difficulty in use, and achieve the purpose of saving the amount of water-reducing agent and improving workability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

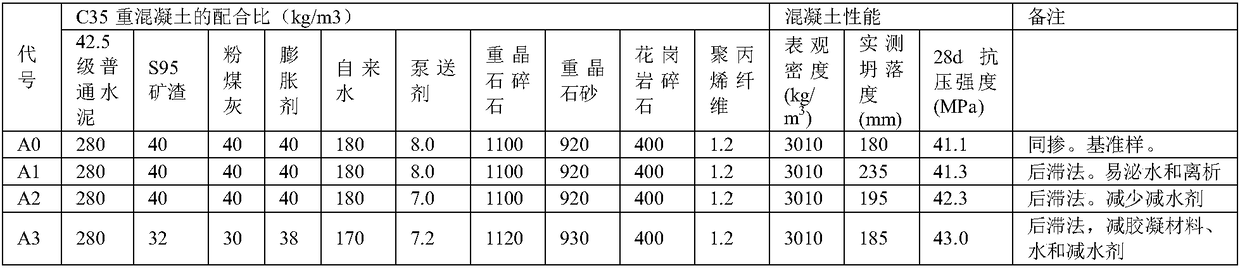

[0026] The raw materials for production are 42.5 grade ordinary Portland cement produced by a group in Zhejiang, S95 slag produced by a slag powder factory in Zhejiang, fly ash (up to FII grade) from a power plant in Zhejiang, self-made granite coarse aggregate (gradation 5~ 25mm, local mine source Hangzhou City), self-made barite coarse aggregate (gradation 5-25mm, mine source Fujian Province), self-made barite fine aggregate (mine source Fujian Province), HEA expansion agent (commercially available), poly Propylene fiber (commercially available) is selected from a pumping agent produced by a group in Zhejiang (mainly polycarboxylate-based high-performance water-reducing agent, and the water-reducing rate of concrete is 27%), and the mixing water is local tap water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com