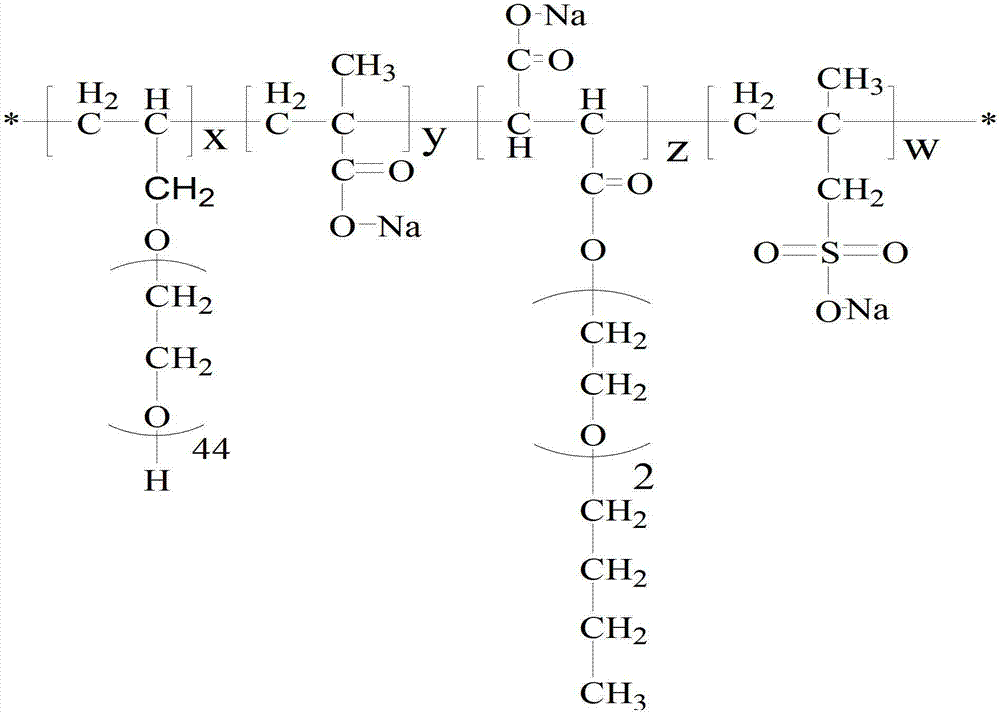

Shrinkage-reducing poly carboxylic acid water reducing agent and preparation method

A technology of polycarboxylic acid and water reducing agent, applied in the field of polycarboxylic acid water reducing agent, can solve problems such as long reaction time, and achieve the effect of reducing shrinkage, excellent performance and improving water reducing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

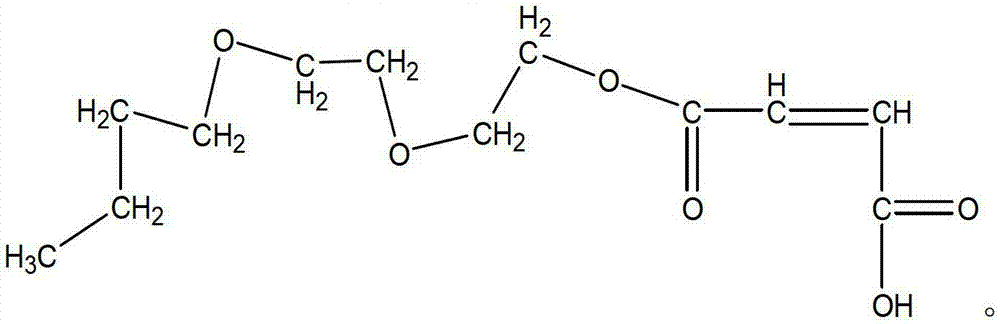

[0025] (1) Preparation of diethylene glycol dimethyl monobutyl ether maleic anhydride monoester (DGMA)

[0026] Add 2mol maleic anhydride (MAD) into a three-necked flask equipped with a thermometer, a stirrer and a reflux condenser, heat to 40°C to melt it, then add 1.5mol diethylene glycol monobutyl ether (DGBE) and 0.03 mol (2% of the mass of diethylene glycol dimethyl monobutyl ether) catalyst, p-toluenesulfonic acid (p-TSA) was heated to 80°C, and after constant temperature esterification for 3 hours, the material was cooled and then purified by vacuum filtration. Obtain diethylene glycol monobutyl ether maleic anhydride monoester (DGMA), its molecular formula is as follows:

[0027]

[0028] (2) Preparation of shrinkage-reducing polycarboxylate superplasticizer with diethylene glycol dimethyl monobutyl ether maleic anhydride monoester (DGMA) as raw material

[0029] In the experimental device equipped with a thermometer, a mechanical stirrer, a condensation reflux dev...

Embodiment 2

[0033] (1) Preparation of diethylene glycol dimethyl monobutyl ether maleic anhydride monoester (DGMA)

[0034] Add 3mol maleic anhydride (MAD) into a three-necked flask equipped with a thermometer, a stirrer and a reflux condenser, heat to 65°C to melt it, then add 0.8mol diethylene glycol monobutyl ether (DGBE) and 0.02 mol (3% of the mass of diethylene glycol dimethyl monobutyl ether) catalyst, p-toluenesulfonic acid (p-TSA) was heated to 140°C, and after constant temperature esterification for 6 hours, the material was cooled and then purified by vacuum filtration. Diethylene glycol monobutyl ether maleic anhydride monoester (DGMA) is obtained.

[0035] (2) Preparation of shrinkage-reducing polycarboxylate superplasticizer with diethylene glycol dimethyl monobutyl ether maleic anhydride monoester (DGMA) as raw material

[0036] In the experimental device equipped with a thermometer, a mechanical stirrer, a condensation reflux device, and a four-necked flask, a mixture of ...

Embodiment 3

[0040] (1) Preparation of diethylene glycol dimethyl monobutyl ether maleic anhydride monoester (DGMA)

[0041] Add 4mol maleic anhydride (MAD) into a three-necked flask equipped with a thermometer, a stirrer and a reflux condenser, heat to 55°C to melt it, then add 0.5mol diethylene glycol monobutyl ether (DGBE) and 0.02 mol (5% of the mass of diethylene glycol dimethyl monobutyl ether) catalyst, p-toluenesulfonic acid (p-TSA) was heated to 135°C, and after constant temperature esterification for 5 hours, the material was cooled and then purified by vacuum filtration. Diethylene glycol monobutyl ether maleic anhydride monoester (DGMA) is obtained.

[0042] (2) Preparation of shrinkage-reducing polycarboxylate superplasticizer with diethylene glycol dimethyl monobutyl ether maleic anhydride monoester (DGMA) as raw material

[0043] In the experimental device equipped with a thermometer, a mechanical stirrer, a condensing reflux device, and a four-necked flask, add a mixture o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com