Preparation method of lithium iron phosphate positive plate with high rate and superior low-temperature performance

A technology of lithium iron phosphate and positive pole piece, which is applied in the field of production of lithium iron phosphate positive pole piece, can solve the problems of high cost, reduced density, large amount of graphene doping, etc., and achieves low cost, rate performance and low temperature performance. Increased, less dosage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

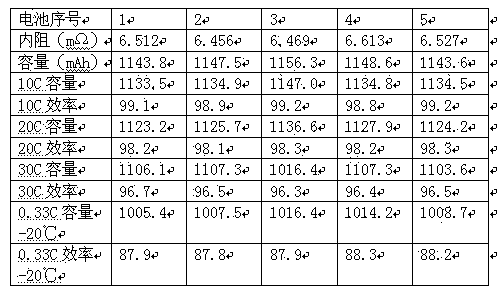

Embodiment 1

[0019] (1) Take a current collector aluminum foil and soak it in 10% lithium chloride solution for 60 minutes, take it out, then wash it with water and dry it to get a pretreated current collector aluminum foil;

[0020] (2) Take 3g of graphene and disperse it in 2L of pure water by ultrasonic to prepare a graphene suspension with a concentration of 1.5g / L;

[0021] (3) Add the binder polyvinyl alcohol to the graphene suspension prepared in step (2) in an amount of 0.15g, heat up to 80°C and stir for 3 hours to fully dissolve, and then apply to the graphene suspension prepared in step (1). On the current collector aluminum foil pretreated by the method described above, and then dry at 110°C in a vacuum state to obtain a graphene-coated current collector aluminum foil, and the thickness of one side of the coated graphene is detected to be 10 microns;

[0022] (4) Take 2.1kg of lithium iron phosphate and dry it under vacuum at 200°C until the water content of lithium iron phosph...

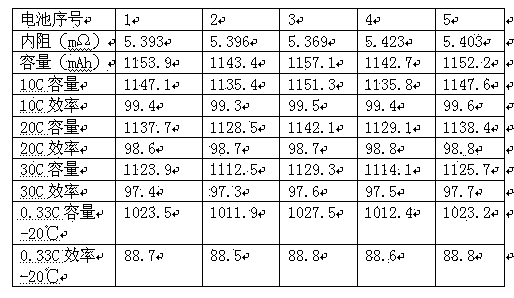

Embodiment 2

[0027] (1) Take a current collector aluminum foil and soak it in 30% lithium chloride solution for 30 minutes, take it out, then wash it with water and dry it to get a pretreated current collector aluminum foil;

[0028] (2) Take 0.6g of graphene and disperse it in 2L of pure water by ultrasonic to prepare a graphene suspension with a concentration of 0.3g / L;

[0029] (3) Add the binder polyvinyl alcohol to the graphene suspension prepared in step (2) in an amount of 0.06g, heat up to 80°C and stir for 3 hours to fully dissolve, and then apply to the graphene suspension prepared in step (1). On the current collector aluminum foil pretreated by the method described above, and then dry at 90°C in a vacuum state to obtain a graphene-coated current collector aluminum foil, and the thickness of one side of the coated graphene is detected to be 1 micron;

[0030] (4) Take 2.1kg of lithium iron phosphate and dry it in a vacuum state at 180°C until the water content of lithium iron ph...

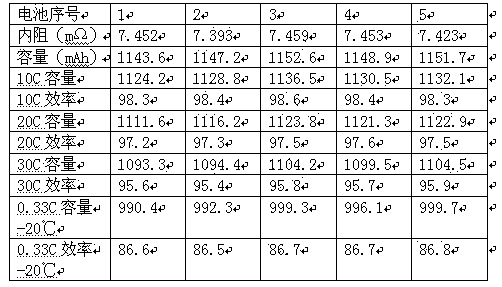

Embodiment 3

[0035] (1) Take a current collector aluminum foil and soak it in 20% lithium chloride solution for 40 minutes, take it out, then wash it with water and dry it to get a pretreated current collector aluminum foil;

[0036] (2) Take 1.6g of graphene and disperse it in 2L of pure water by ultrasonic to prepare a graphene suspension with a concentration of 0.8g / L;

[0037] (3) Add the binder polyvinyl alcohol to the graphene suspension prepared in step (2), the addition amount is 0.12g, heat up to 80°C and stir for 3 hours to fully dissolve, and then apply to the graphene suspension prepared in step (1). On the current collector aluminum foil pretreated by the method described above, and then dry at 100°C in a vacuum state to obtain a graphene-coated current collector aluminum foil, and the thickness of one side of the coated graphene is detected to be 5 microns;

[0038] (4) Take 2.1kg of lithium iron phosphate and dry it under vacuum at 190°C until the water content of lithium ir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| discharge efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com