Electric furnace steel slag-based cement admixture or concrete admixture as well as preparation method and application thereof

A technology of electric furnace steel slag and mixed materials, which is applied in the direction of cement production, etc., can solve the problems of less than 30% of comprehensive utilization rate, ineffective utilization, pollution of the environment, etc., and achieve the improvement of late hydration activity, high hydration activity, and mixing low volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] First, carry out the pretreatment of crushing-magnetic separation-secondary crushing-magnetic separation-coarse grinding-magnetic separation on the refined steel slag of ladle furnace, so that the particle size is 2 / kg of micropowder, namely obtain the electric furnace steel slag-based cement admixture or concrete admixture Example 1.

Embodiment 2

[0053] Firstly, the pretreatment of crushing-magnetic separation-secondary crushing-magnetic separation-coarse grinding-magnetic separation is carried out on the refined steel slag of ladle furnace, so that the particle size is less than 2mm, and the content of metal elemental iron is less than 1%; secondly, take 10 parts of three Ethylene glycol, 20 parts of molasses, 25 parts of sodium nitrate and 50 parts of water are uniformly mixed to prepare an admixture; then, 93 parts of pretreated refined steel slag are uniformly mixed with 2 parts of phosphogypsum and 5 parts of lithium slag, and 0.1 Parts of admixture are evenly sprayed or sprayed on the above-mentioned mixed solid material; finally, the above-mentioned material is ground in a ball mill to a specific surface area of 420±10m 2 / kg of micropowder, namely obtain the electric furnace steel slag-based cement admixture or concrete admixture Example 2.

Embodiment 3

[0055] First, carry out the pretreatment of crushing-magnetic separation-secondary crushing-magnetic separation-coarse grinding-magnetic separation on the refined steel slag of ladle furnace, so that the particle size is less than 2mm, and the content of metal elemental iron is less than 1%; secondly, take 8 parts of three Ethylene glycol, 15 parts of molasses, 17 parts of sodium nitrate and 60 parts of water were uniformly mixed to prepare an admixture; then, 87 parts of pretreated refined steel slag were uniformly mixed with 5 parts of phosphogypsum and 8 parts of lithium slag, and 0.15 100% admixture is evenly sprayed or sprayed on the mixed solid material; finally, the above material is ground in a ball mill to a fine powder with a specific surface area of 420±10m2 / kg, and the electric furnace steel slag-based cement admixture or concrete admixture is obtained Example 3.

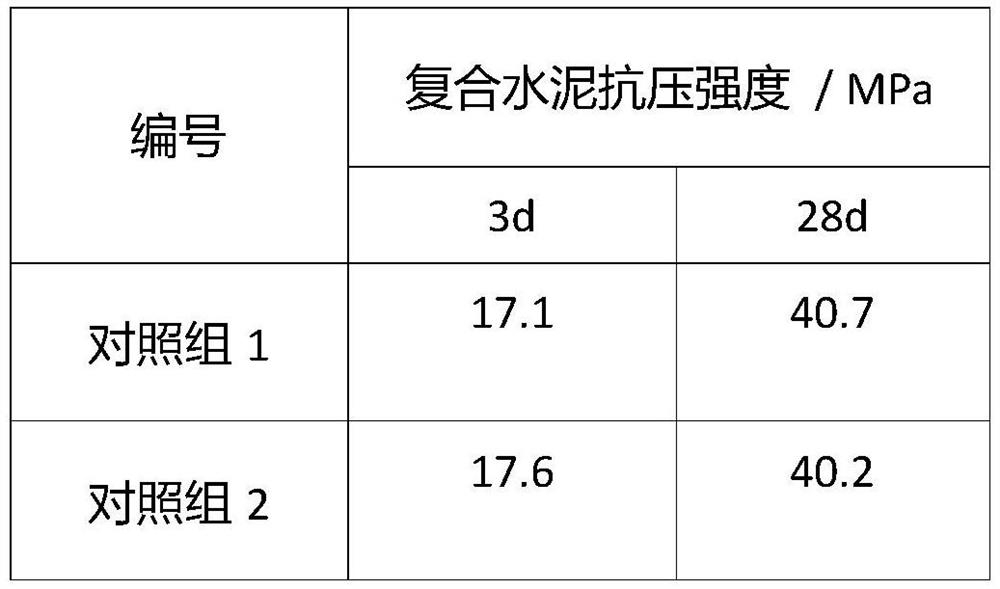

[0056] The electric furnace steel slag-based cement admixture or concrete admixture prepared by the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com