Preparation method of stable rubber modified asphalt

A rubber modification and stabilization technology, which is applied in building components, building insulation materials, construction, etc., can solve the problems of unsuitability for large-scale application, segregation of modified asphalt, poor stability, etc., to achieve large-scale application and stable product performance , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

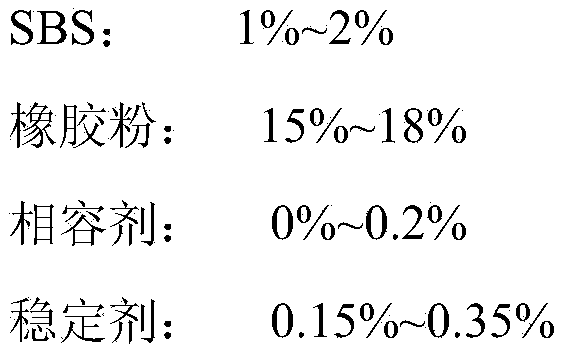

[0025] The preparation method of stable type rubber modified asphalt of the present invention comprises the following steps:

[0026] 1) Select No. 70 road petroleum asphalt as the base asphalt, put the base asphalt in a mixer, and heat it to 170-180°C;

[0027] 2) Add SBS, rubber powder and compatibilizer to the above base asphalt, start the mixer to start stirring, and slowly adjust the speed to 2500-3000r / min during the stirring process, the whole stirring process is 45-55min; the speed is 2500- The stirring time of 3000r / min is 15-25min, the temperature is controlled at 180-190°C, the specification of the rubber powder is 30 mesh or 40 mesh, and the compatibilizer is rubber oil;

[0028] 3) Add a stabilizer to the mixture after the above stirring is completed, place it in a high-speed shearing machine, immerse the rotor of the shearing machine in the mixture to preheat for 1 to 2 minutes, and then turn on the shearing machine. During the shearing process, slow Slowly adju...

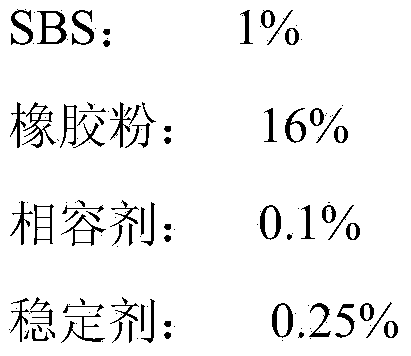

Embodiment 1

[0039] The following components were weighed by mass: 1 part of SBS, 16 parts of rubber powder (30 mesh), 0.1 part of rubber oil, 0.25 part of sulfur, and 82.65 parts of No. 70 road petroleum asphalt.

[0040] 1) Select No. 70 road petroleum asphalt as the base asphalt, put the base asphalt in a mixer, and heat it to 170°C;

[0041] 2) Add SBS, rubber powder and rubber oil to the above-mentioned matrix asphalt, start the mixer to start stirring, slowly adjust the speed to 3000r / min during the stirring process, and the whole stirring process is 45min; the stirring time when the speed is 3000r / min is 20min, the temperature is controlled at 180°C;

[0042] 3) Add sulfur to the mixture after the above stirring is completed, place it in a high-speed shearing machine, immerse the rotor of the shearing machine in the mixture to preheat for 1 to 2 minutes, then turn on the shearing machine, and slowly Adjust the rotation speed to 2500r / min, and the whole shearing process takes 15-18 ...

Embodiment 2

[0046] The following components were weighed by mass: 1.5 parts of SBS, 15 parts of rubber powder (40 mesh), 0.2 parts of rubber oil, 0.15 parts of sulfur, and 83.15 parts of No. 70 road petroleum asphalt.

[0047] 1) Select No. 70 road petroleum asphalt as the base asphalt, put the base asphalt in a mixer, and heat it to 180°C;

[0048] 2) Add SBS, rubber powder and rubber oil to the above-mentioned matrix asphalt, start the mixer to start stirring, slowly adjust the speed to 2500r / min during the stirring process, and the whole stirring process is 55min; the stirring time for the speed of 2500r / min is 25min, the temperature is controlled at 190°C;

[0049] 3) Add sulfur to the mixture after the above stirring is completed, place it in a high-speed shearing machine, immerse the rotor of the shearing machine in the mixture to preheat for 1 to 2 minutes, then turn on the shearing machine, and slowly Adjust the rotation speed to 3000r / min, and the whole shearing process takes 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com