Mass concrete and preparation process thereof

A large-volume concrete and retarder technology, applied in the field of concrete, can solve the problems of concrete temperature deformation, cracks, poor heat transfer performance of concrete, etc., and achieve the effect of enhancing structural strength, slowing down the solidification speed, and reducing the solidification speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

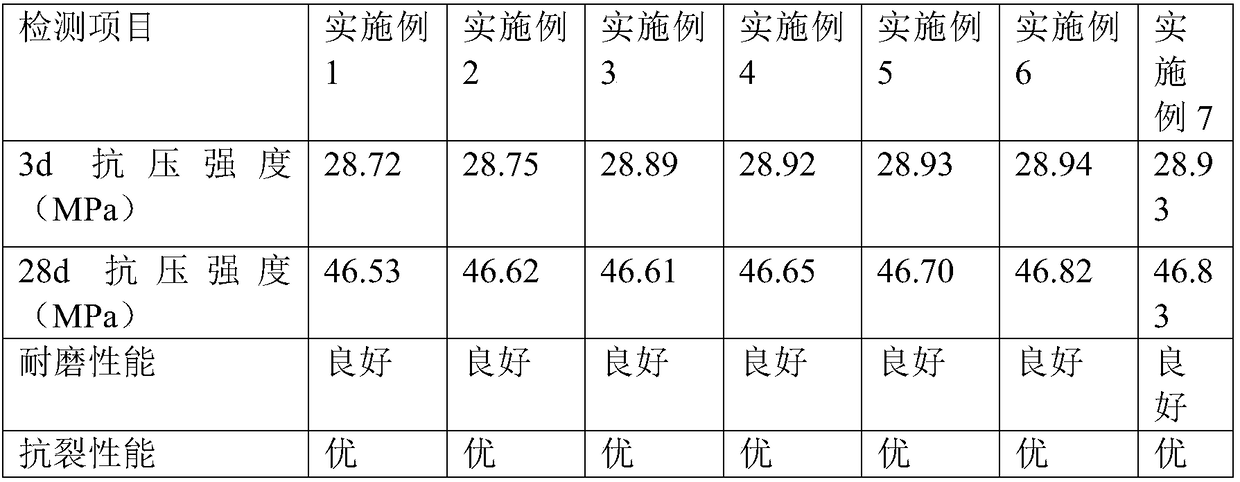

Examples

Embodiment 1

[0032] A mass concrete, comprising the following components in parts by weight: 230 parts of cement, 110 parts of fly ash, 160 parts of water, 75 parts of mineral powder, 850 parts of medium sand, and 735 parts of gravel with a particle size of 5-25 mm , 220 parts of gravel with a particle size of 5-10mm, 1 part of copolymerized methacrylic acid, 0.001 part of sugar calcium, and 7 parts of methacrylic acid.

Embodiment 2

[0034] A mass concrete, comprising the following components in parts by weight: 231 parts of cement, 112 parts of fly ash, 161 parts of water, 76 parts of mineral powder, 852 parts of medium sand, and 736 parts of gravel with a particle size of 5-25 mm , 221 parts of gravel with a particle size of 5-10mm, 1.1 parts of polyisoprene polyoxyethylene ether, 0.002 parts of calcium gluconate, and 7.1 parts of maleic anhydride.

Embodiment 3

[0036] A mass concrete, comprising the following components in parts by weight: 232 parts of cement, 114 parts of fly ash, 162 parts of water, 77 parts of mineral powder, 854 parts of medium sand, and 737 parts of gravel with a particle size of 5-25 mm , 222 parts of gravel with a particle size of 5-10 mm, 1.2 parts of copolymerized methacrylic acid, 0.003 parts of 3-hydroxy-1,3,5-pentanetrionic acid, and 7.2 parts of sodium lignosulfonate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com