Composite conductive paste for anodes and cathodes of lithium ion batteries as well as preparation method for composite conductive paste

A lithium-ion battery, composite conductive technology, applied in the direction of electrode manufacturing, battery electrodes, conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of cycle life, energy density, electrochemical performance, etc. Effects of electrochemical performance, internal resistance reduction, and capacity increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

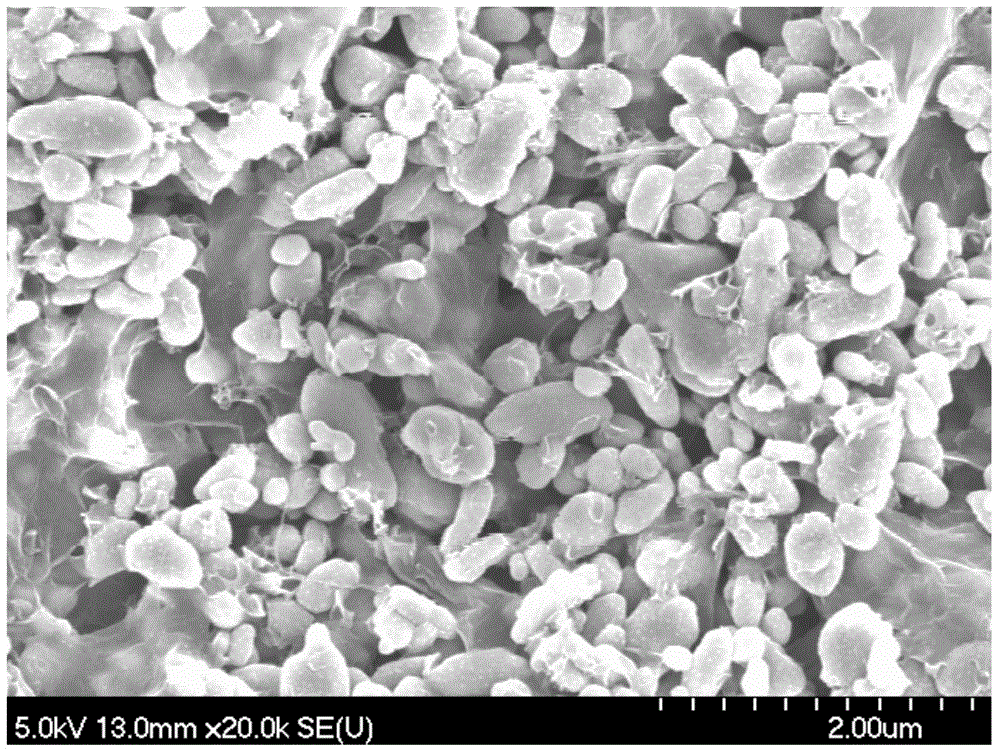

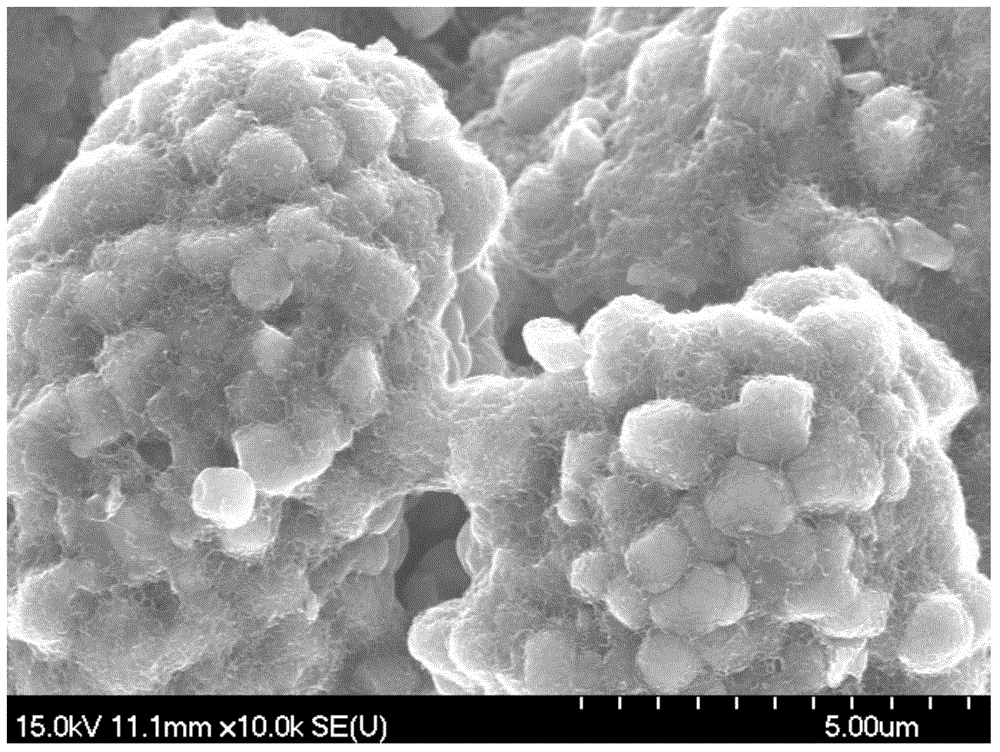

Image

Examples

preparation example Construction

[0025] The composite conductive paste for positive and negative electrodes of lithium-ion batteries provided by the embodiments of the present invention can be prepared by the following method, and of course, other composite conductive pastes for positive and negative electrodes of lithium-ion batteries can also be obtained method for preparation. Correspondingly, the embodiment of the present invention also provides a method for preparing a composite conductive paste for positive and negative electrodes of lithium-ion batteries, comprising the following steps:

[0026] S01. Weigh each component according to the formula of the above-mentioned composite conductive paste for positive and negative electrodes of lithium-ion battery;

[0027] S02. dissolving polyvinylpyrrolidone in N-methylpyrrolidone to obtain a mixed solution;

[0028] S03. Add carbon nanotubes to the mixed solution, perform infiltration and dispersion treatment, and form a dispersion system;

[0029] S04. Add ...

Embodiment 1

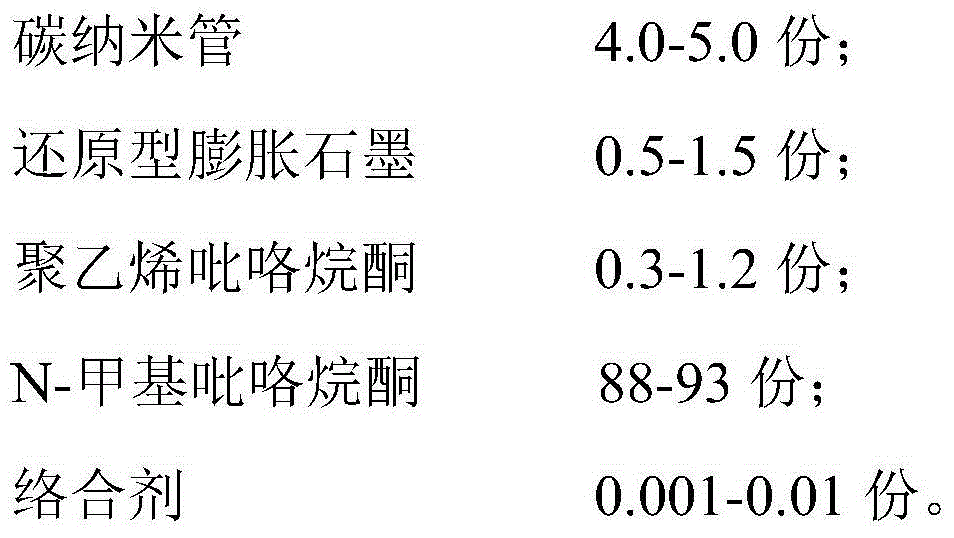

[0042] A conductive paste for positive and negative electrodes of lithium-ion batteries, comprising the following formulation components in the following parts by weight:

[0043]

[0044] The preparation method of the composite conductive paste for lithium ion battery positive and negative electrodes is:

[0045] S11. Weigh each component according to the formula of the above-mentioned composite conductive paste for positive and negative electrodes of lithium ion battery;

[0046] S12. In a dehumidified environment at room temperature (humidity lower than 30% R.Hs), pour the solvent N-methylpyrrolidone into the sand mill, slowly pour the dispersant polyvinylpyrrolidone into the sand mill and keep stirring at a low speed Make a solution until the dispersant is completely dissolved;

[0047] S13. Turn on the 20°C cooling circulating water to make the slurry temperature 40°C during the sand milling process, pour the carbon nanotubes into the solvent in the sand mill, and sti...

Embodiment 2

[0051] A conductive paste for positive and negative electrodes of lithium-ion batteries, comprising the following formulation components in the following parts by weight:

[0052]

[0053] The preparation method of the composite conductive paste for lithium ion battery positive and negative electrodes is:

[0054] S21. Weigh each component according to the formula of the above-mentioned composite conductive paste for positive and negative electrodes of lithium-ion batteries;

[0055] S22. In a dehumidified environment at room temperature (humidity lower than 30% R.Hs), pour the solvent N-methylpyrrolidone into the sand mill, slowly pour the dispersant polyvinylpyrrolidone into the sand mill and keep stirring at a low speed Make a solution until the dispersant is completely dissolved;

[0056] S23. Turn on the cooling circulating water at 20°C so that the temperature of the slurry is between 30°C during the sand milling process, pour the carbon nanotubes into the solvent in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com