Rubber sealing member

A technology of rubber seals and rubber raw materials, applied in the field of rubber seals and seals, can solve the problems of affecting the service life of seals, poor high temperature resistance, poor wear resistance, etc., to improve the service life and increase the compressive strength. , The effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

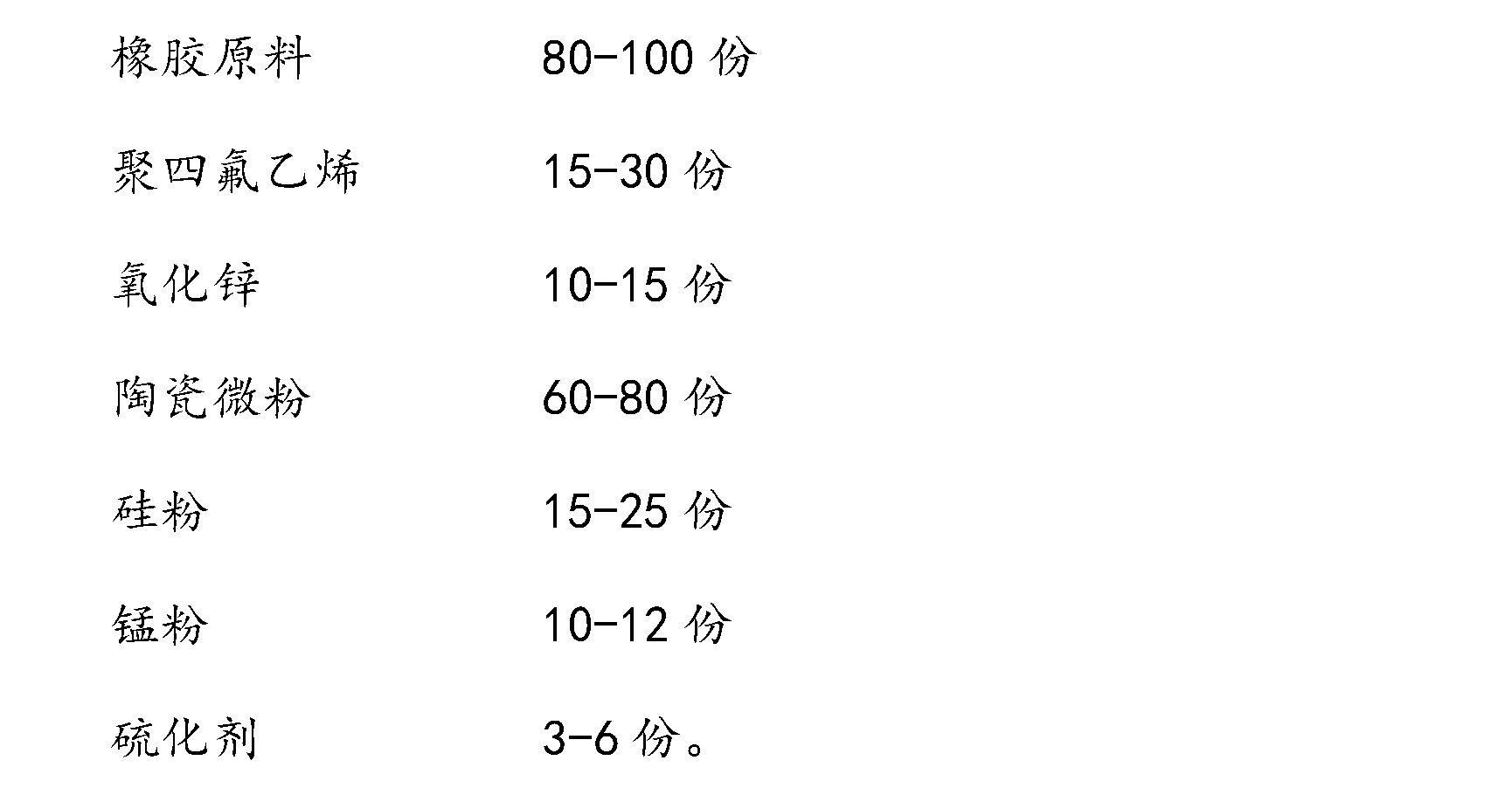

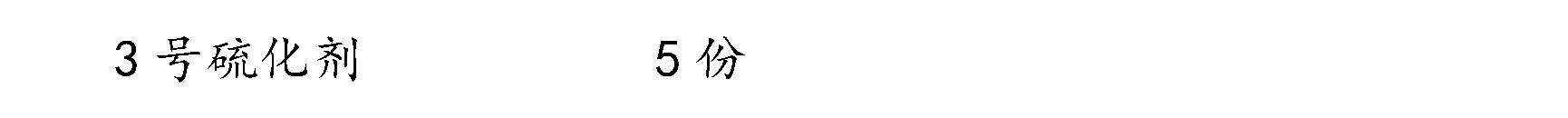

[0019] A rubber seal, composed of 80 parts of rubber raw materials, 15 parts of polytetrafluoroethylene, 10 parts of zinc oxide, 60 parts of ceramic micropowder, 15 parts of silicon powder, 10 parts of manganese powder, and 3 parts of vulcanizing agent, calculated in parts by weight First, nitrile rubber, fluororubber, styrene-butadiene rubber and polyimide resin are masticated for 15 to 30 minutes to form rubber raw materials, nitrile rubber: fluororubber: styrene-butadiene rubber: polyimide resin is 2:3:2 : 1.5, weight ratio, until the plasticity test meets the process requirements, add 60 parts of ceramic micropowder, 15 parts of silicon powder, and 10 parts of manganese powder in turn until fully mixed, then add 3 parts of vulcanizing agent, and mix thoroughly , the final film. The rubber seal prepared by the formula has medium resistance and can still work under high temperature environment, and has good elasticity. The vulcanizing agent is composed of 5 parts of No. 3 v...

Embodiment 2

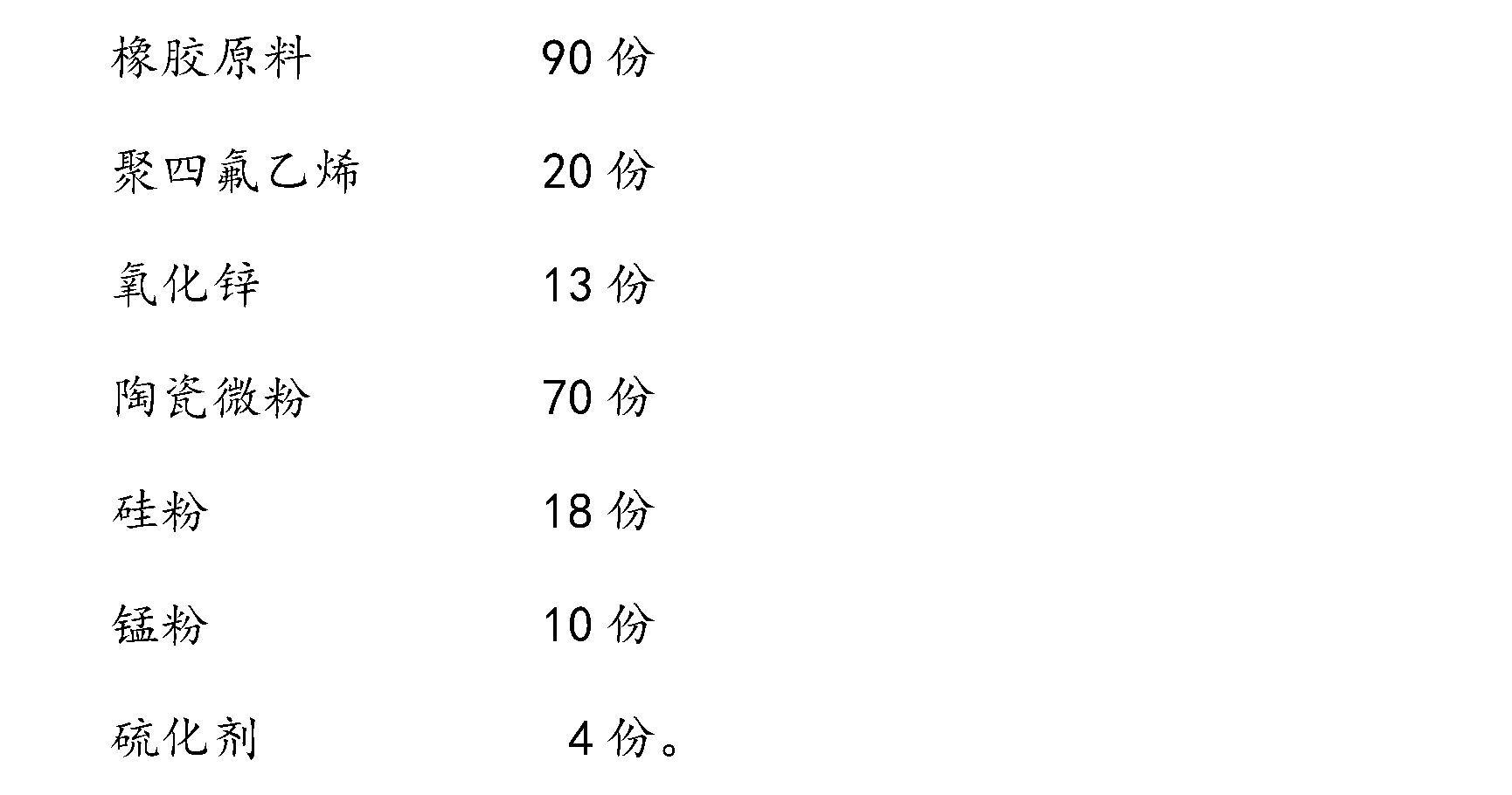

[0022] A rubber seal, consisting of 90 parts of rubber raw materials, 20 parts of polytetrafluoroethylene, 13 parts of zinc oxide, 70 parts of ceramic micropowder, 18 parts of silicon powder, 10 parts of manganese powder, and 4 parts of vulcanizing agent, calculated in parts by weight First, nitrile rubber, fluororubber, styrene-butadiene rubber and polyimide resin are masticated for 15 to 30 minutes to form rubber raw materials, nitrile rubber: fluororubber: styrene-butadiene rubber: polyimide resin is 2:3:2 : 1.5, weight ratio, until the plasticity test meets the process requirements, add 70 parts of ceramic micropowder, 18 parts of silicon powder, and 10 parts of manganese powder in turn until fully mixed, then add 4 parts of vulcanizing agent, and mix thoroughly , the final film. The rubber seal prepared by the formula has medium resistance and can still work under high temperature environment, and has good elasticity. The vulcanizing agent is composed of 5 parts of No. 3...

Embodiment 3

[0025] A rubber seal, consisting of 100 parts of rubber raw material, 30 parts of polytetrafluoroethylene, 15 parts of zinc oxide, 80 parts of ceramic micropowder, 25 parts of silicon powder, 12 parts of manganese powder, and 6 parts of vulcanizing agent, calculated in parts by weight First, nitrile rubber, fluororubber, styrene-butadiene rubber and polyimide resin are masticated for 15 to 30 minutes to form rubber raw materials, nitrile rubber: fluororubber: styrene-butadiene rubber: polyimide resin is 2:3:2 : 1.5, weight ratio, until the plasticity test meets the process requirements, add 80 parts of ceramic micropowder, 25 parts of silicon powder, and 12 parts of manganese powder in turn until fully mixed, then add 6 parts of vulcanizing agent, and mix thoroughly , the final film. The rubber seal prepared by the formula has medium resistance and can still work under high temperature environment, and has good elasticity. The vulcanizing agent is composed of 5 parts of No. 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com