Sandwich structure pre-lithiated negative electrode and lithium ion battery

A sandwich and pre-lithiation technology, used in battery electrodes, secondary batteries, structural parts, etc., can solve problems such as reducing the unit energy density of batteries, and achieve the effect of reducing self-discharge behavior, suitable for mass production, and reducing etching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

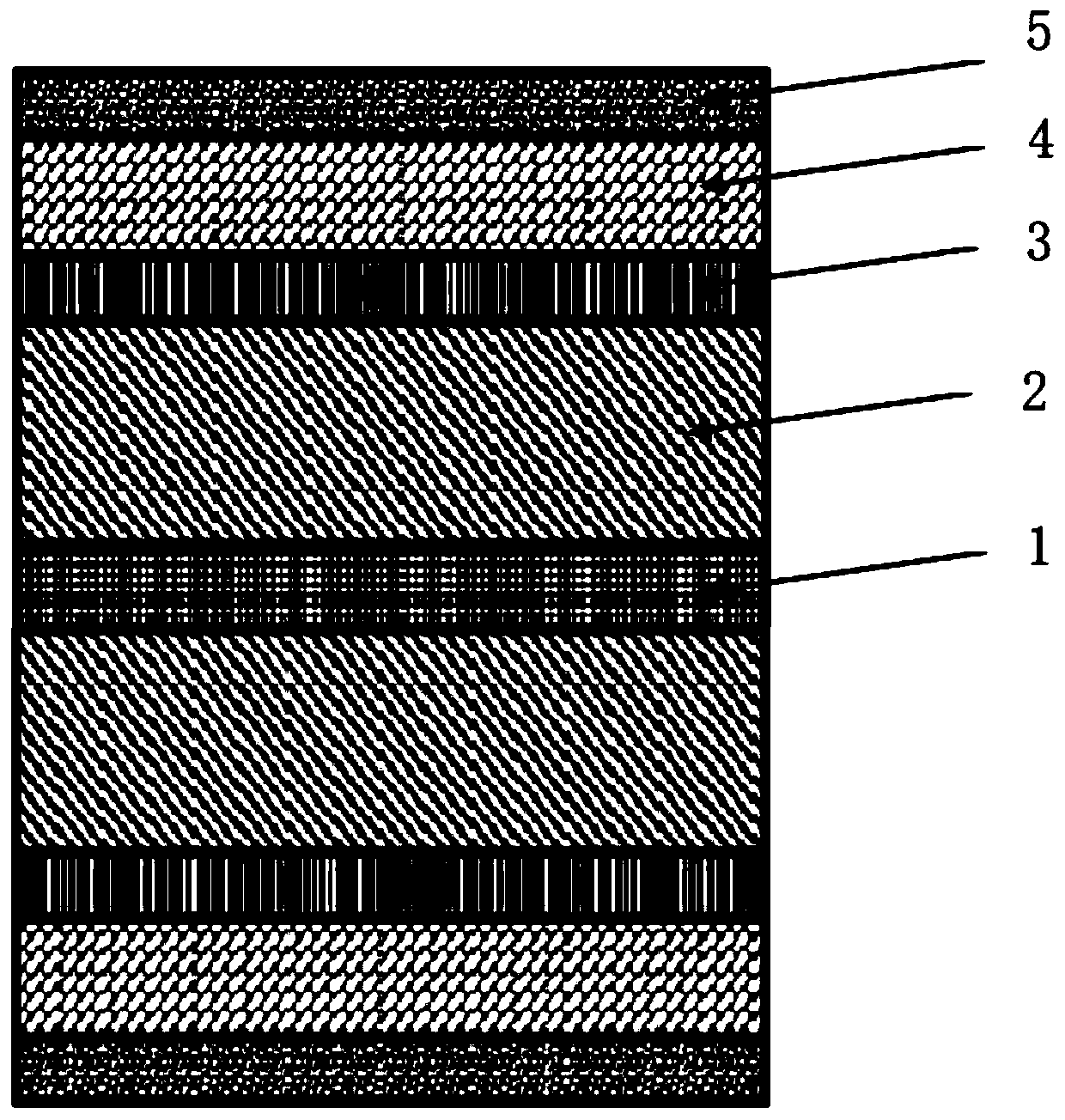

[0051] A sandwich structure pre-lithiated negative electrode, comprising a negative electrode current collector, a negative electrode active layer is arranged above the negative electrode current collector, and a sandwich structure is arranged above the negative electrode active layer;

[0052] The sandwich structure includes a primary protection layer, a lithium-containing metal layer, and a secondary protection layer, the lithium-containing metal layer is located between the primary protection layer and the secondary protection layer, and the secondary protection layer is layer is located above the primary protective layer, and the primary protective layer is located on the negative electrode active layer.

[0053] The negative electrode current collector adopts pure copper foil with a thickness of 12 μm, the negative electrode active material is silicon oxide / graphite composite material, the unit capacity is 600mAh / g, and it also contains conductive agent carbon black, CMC, ...

Embodiment 2

[0067] A sandwich structure pre-lithiated negative electrode, comprising a negative electrode current collector, a negative electrode active layer is arranged above the negative electrode current collector, and a sandwich structure is arranged above the negative electrode active layer;

[0068] The sandwich structure includes a primary protection layer, a lithium-containing metal layer, and a secondary protection layer, the lithium-containing metal layer is located between the primary protection layer and the secondary protection layer, and the secondary protection layer is layer is located above the primary protective layer, and the primary protective layer is located on the negative electrode active layer.

[0069] The negative electrode current collector adopts a carbon-coated copper foil with a thickness of 14 μm, and the negative electrode active material is silicon oxide / graphite composite material, and also contains conductive agent carbon black, PVDF, silicon oxide / grap...

Embodiment 3

[0083] A sandwich structure pre-lithiated negative electrode, comprising a negative electrode current collector, a negative electrode active layer is arranged above the negative electrode current collector, and a sandwich structure is arranged above the negative electrode active layer;

[0084] The sandwich structure includes a primary protection layer, a lithium-containing metal layer, and a secondary protection layer, the lithium-containing metal layer is located between the primary protection layer and the secondary protection layer, and the secondary protection layer is layer is located above the primary protective layer, and the primary protective layer is located on the negative electrode active layer.

[0085] The negative electrode current collector adopts a copper foil with a thickness of 12 μm, and the negative electrode active material is a soft carbon material, which also includes conductive agent carbon black, PVDF, soft carbon, conductive agent carbon black, and P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com