Room temperature crosslinkage and curable styrene-acrylate emulsion, and its preparation method

A styrene-acrylic emulsion, room temperature cross-linking technology, used in coatings, anti-corrosion coatings, epoxy resin coatings, etc., to achieve excellent mechanical properties, outstanding anti-corrosion properties, and excellent anti-corrosion properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further explained below in conjunction with specific examples, but the specific examples do not limit the present invention in any way. Unless otherwise specified, the reagents and methods involved in the examples are commonly used reagents and methods in the art.

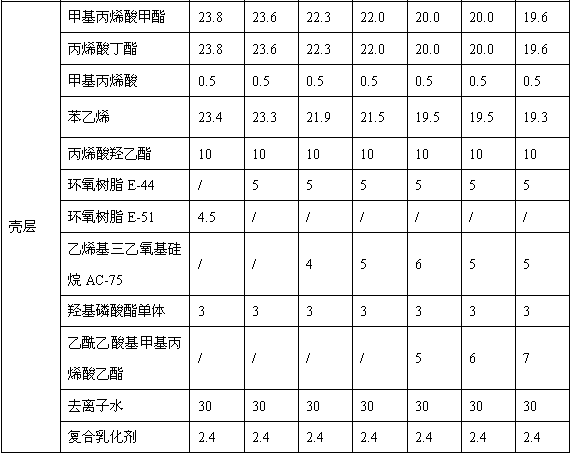

[0059] Embodiment 1~7 prepares the styrene-acrylic emulsion that can be cross-linked and cured at room temperature

[0060] (1) Raw materials and their proportions (see Table 1). In Examples 1 to 7, the emulsion formula is calculated based on a solid content of 50% (the solid content varies within ±5%, which will not substantially affect the performance of the product. sexual effects).

[0061] In Table 1, the composite emulsifier used is a mixture of alkyl polyoxyethylene ether sulfate LA-083 and nonionic emulsifier LCN-407 in a weight ratio of 1:1.

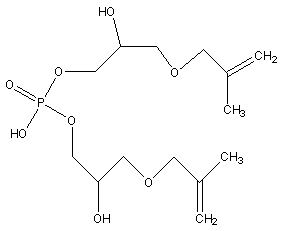

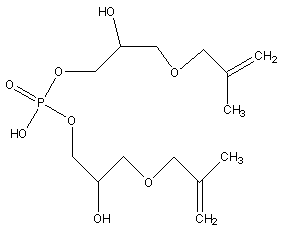

[0062] The hydroxyphosphate monomer is a 1:1 mixture of a monoester monomer represented by formula (I) and a diester monomer r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com