Method and device for treating daub and iron-rich heavy metal solid waste of waste lead-acid storage battery

A technology of waste lead-acid batteries and heavy metals, which is applied in the direction of improving process efficiency, etc., can solve the hidden dangers of heavy metal pollution, the continuous cleaning and smelting of waste lead-acid battery clay, iron-rich heavy metal solid waste, idle waste of resources and other problems, to achieve elimination Effects of gas pollution, clean and efficient recycling, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

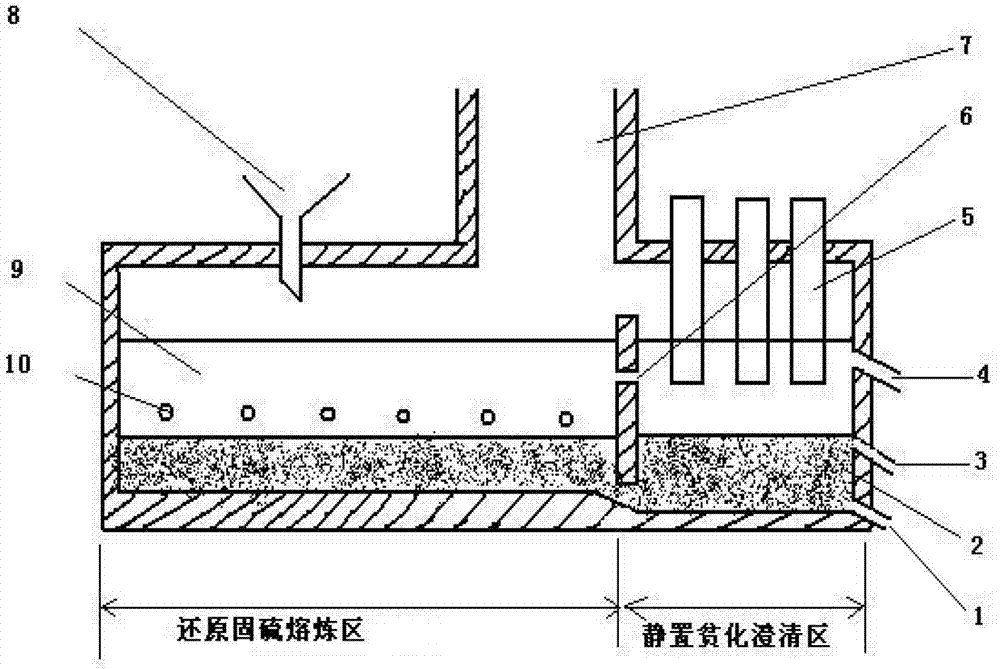

Method used

Image

Examples

Embodiment 1

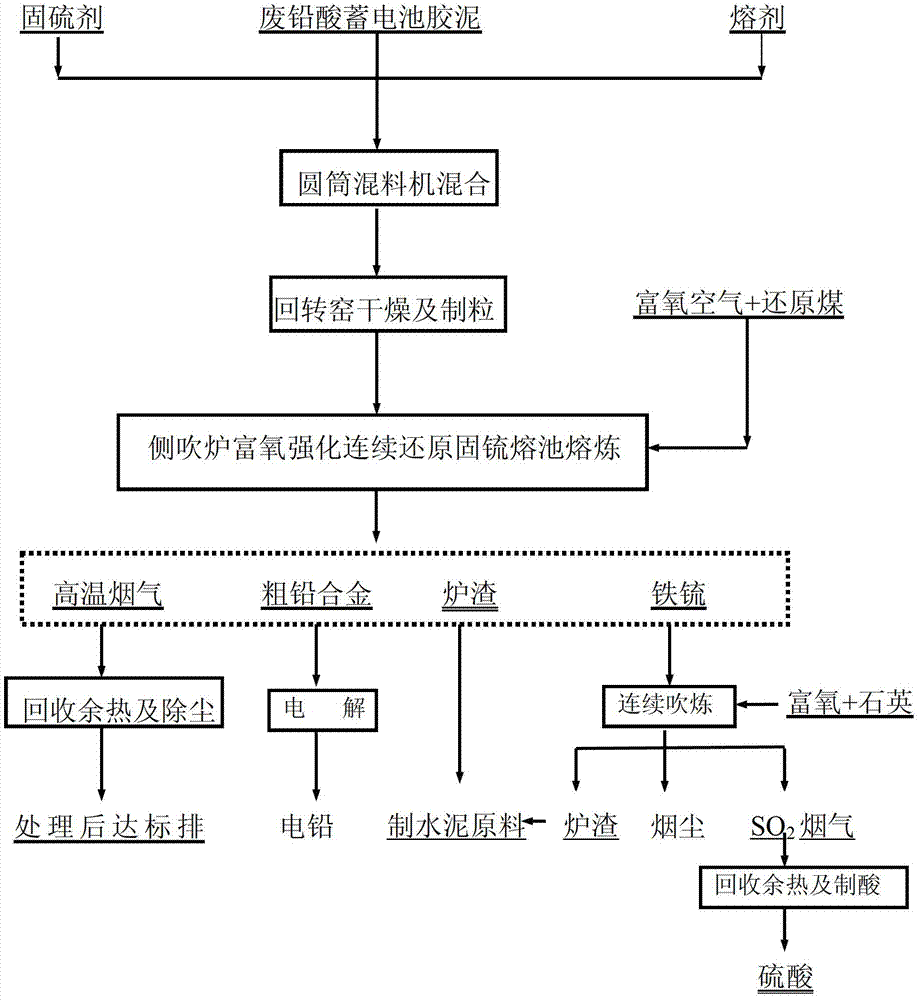

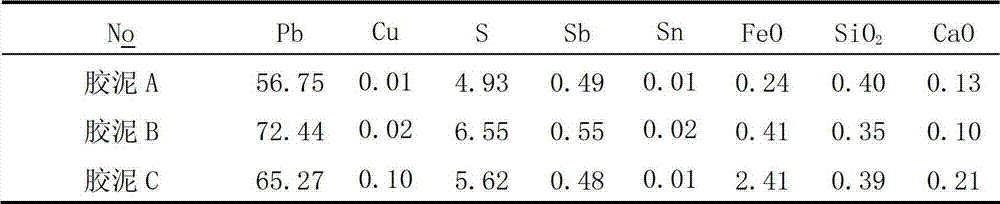

[0058] The smelting of embodiment 1 cement A

[0059] Take 400t of cement A, 110t of pyrite slag A, and 16t of limestone to prepare 526t of charge, and its main components (%) are: Pb43.22, S4.02, FeO11.62, SiO 2 5.06, CaO2.53. Then mix and granulate in batches in the mixer, and then add 130t of reduced coal, then add the dry pellets and reduced coal continuously into 2M 2 In the oxygen-enriched side-blowing furnace, the cross-sectional area of the tuyere area of the side-blowing furnace is 2m 2 ,; Melting temperature 1050 ℃ ~ 1300 ℃, wind pressure 3.0 ~ 5.0 atmospheres, air volume 200 ~ 400m 3 / min, oxygen concentration 40~60%, slag temperature 1150℃; continuous smelting for 5 days and 2 hours, total output:

[0060] Crude lead 210.3t, containing Pb 98%, lead yield 90.65%;

[0061] Soot 35.4t, containing Pb 41.22%, lead recovery rate 97.07%;

[0062] Water-quenched slag 125t, containing Pb 1.55%, S 1.59%, FeO 37.72%, SiO 2 29.37%, CaO 11.37%;

[0063] Iron matte 8...

Embodiment 2

[0065] The smelting of embodiment 2 cement B

[0066] Take 400t of cement B, 160t of pyrite slag B, and 16t of limestone to prepare 576t of charge. The main components (%) are: Pb50.30, S5.48, FeO15.80, SiO 2 6.44, CaO2.25, and then mixed in batches in the mixer and granulated, and then added 150t of reduced coal, and then added the dry pellets and reduced coal continuously into 2M 2 In the oxygen-enriched side-blowing furnace, the cross-sectional area of the tuyere area of the side-blowing furnace is 2m 2 , Melting temperature 1050℃~1250℃, wind pressure 2~5 atmospheres, air volume 200~450m 3 / min, oxygen concentration 35~60%, continuous smelting for 6 days, total output:

[0067] Crude lead 265.7t, containing Pb 97.67%, lead yield 89.56%;

[0068] Soot 44t, containing Pb 47.65%, lead recovery rate 96.79%;

[0069] Water-quenched slag 105t, containing Pb 1.72%, S 2.51%, FeO 35.71%, SiO 2 29.06%, CaO 12.13%;

[0070] Iron matte 122t, containing Pb 6.13%, S 23.50%, Fe...

Embodiment 3

[0072] The smelting of embodiment 3 cement C

[0073] Take 400t of cement C, 110t of kiln slag magnetic separation iron slag, and 16t of limestone, and prepare 526t of charge. The main components (%) are: Pb49.70, S4.55, FeO15.67, SiO 2 5.17, CaO2.12. Then mix and granulate in batches in the mixer, and then add 130t of reduced coal, then add the dry pellets and reduced coal continuously into 2M 2 In the oxygen-enriched side-blowing furnace, the cross-sectional area of the tuyere area of the side-blowing furnace is 2m 2 , Melting temperature 1050℃~1300℃, wind pressure 4.2~4.5 atmospheres, air volume 250~340m 3 / min, oxygen concentration 40~60%, slag temperature 1150℃; continuous smelting for 6 days, total output:

[0074] Crude lead 243.5t, containing Pb 97.77%, lead yield 91.08%;

[0075] Soot 34t, containing Pb 47.35%, lead recovery rate 97.23%;

[0076] Water-quenched slag 98t, containing Pb 1.95%, S 0.68%, FeO 32.84%, SiO 2 26.35%, CaO 10.29%;

[0077] Iron matt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com