A method and device for preparing gas from high ash coal

A high-ash coal and gas technology, applied in the direction of manufacturing combustible gas, granular/powdered fuel gasification, gasification process, etc., can solve problems such as poor adaptability, reduce gas production costs, reduce heat demand, and reduce gas costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

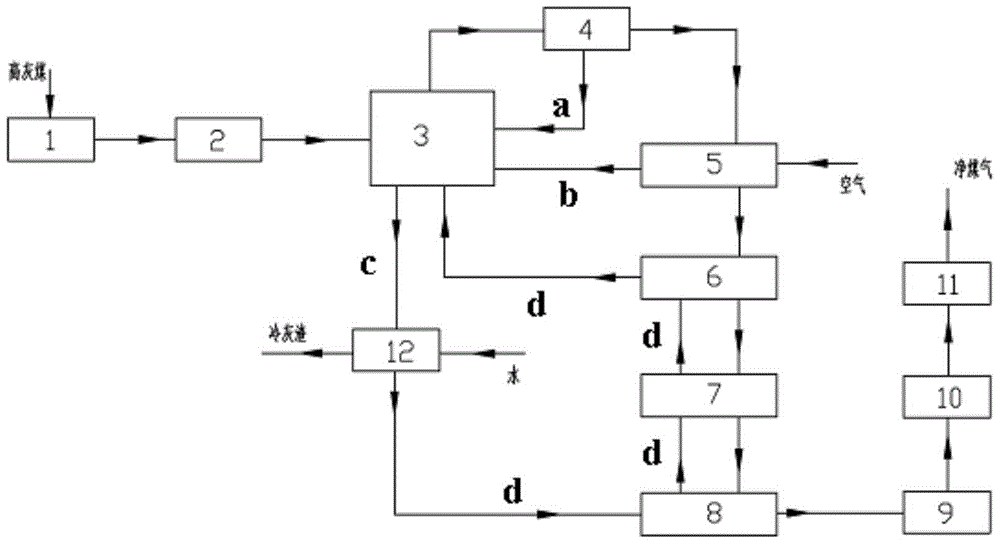

Method used

Image

Examples

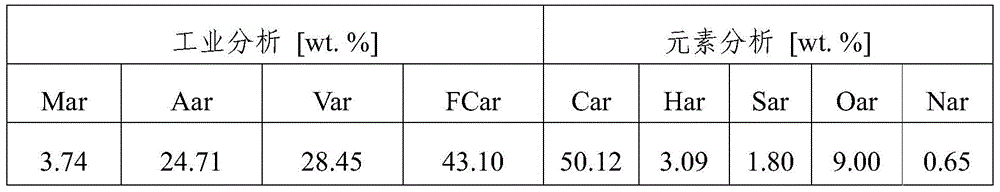

Embodiment 1

[0053] Prepare gas as follows:

[0054] (1) get the high ash coal, after crushing and screening pretreatment successively, obtain the gasification raw material whose particle diameter is greater than 6mm and less than 1% of the total amount;

[0055] (II) Under the action of a gasification agent at 600°C, the gasification raw material undergoes primary pyrolysis gasification at 850°C, and then performs secondary pyrolysis gasification at 1000°C to obtain high-temperature gas and ash;

[0056] At the same time, the obtained ash is exchanged with softened cold water, and after the ash is cooled to room temperature, the cold ash is obtained;

[0057] (III) Carrying out high-temperature dust removal on the high-temperature gas to remove fly ash to obtain a once-purified high-temperature gas with a temperature of 1000° C.;

[0058] At the same time, the obtained fly ash is used as a gasification raw material, and is subjected to cyclic pyrolysis and gasification through step (II);...

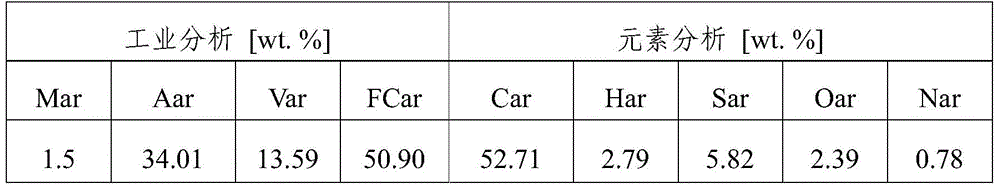

Embodiment 2

[0064] Prepare gas as follows:

[0065] (1) get the high-ash coal, after crushing and screening pretreatment successively, obtain the gasification raw material whose particle diameter is greater than 6mm and less than 2% of the total amount;

[0066] (II) Under the action of a gasification agent at 500°C, the gasification raw material undergoes primary pyrolysis gasification at 850°C, and then performs secondary pyrolysis gasification at 950°C to obtain high-temperature gas and ash;

[0067] At the same time, the obtained ash is exchanged with softened cold water, and after the ash is cooled to room temperature, the cold ash is obtained;

[0068] (III) Perform high-temperature dust removal on the high-temperature gas to remove fly ash to obtain a once-purified high-temperature gas with a temperature of 900° C.;

[0069] At the same time, the obtained fly ash is used as a gasification raw material, and is subjected to cyclic pyrolysis and gasification through step (II);

[00...

Embodiment 3

[0075] Prepare gas as follows:

[0076] (1) get the high-ash coal, after crushing and screening pretreatment successively, obtain the gasification raw material whose particle diameter is greater than 6mm and less than 3% of the total amount;

[0077] (II) Under the action of a gasification agent at 650°C, the gasification raw material undergoes primary pyrolysis gasification at 950°C, and then performs secondary pyrolysis gasification at 1100°C to obtain high-temperature gas and ash;

[0078] At the same time, the obtained ash is exchanged with softened cold water, and after the ash is cooled to room temperature, the cold ash is obtained;

[0079] (III) Carrying out high-temperature dust removal on the high-temperature gas to remove fly ash to obtain a once-purified high-temperature gas with a temperature of 1100° C.;

[0080] At the same time, the obtained fly ash is used as a gasification raw material, and is subjected to cyclic pyrolysis and gasification through step (II);...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com