A kind of processing method of stone coal

A treatment method, stone coal technology, applied in the field of comprehensive utilization of resources, can solve problems such as high cost, low added value, complex resource recovery process, etc., and achieve the effect of breaking through the bottleneck of inefficiency, obvious economic benefits and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

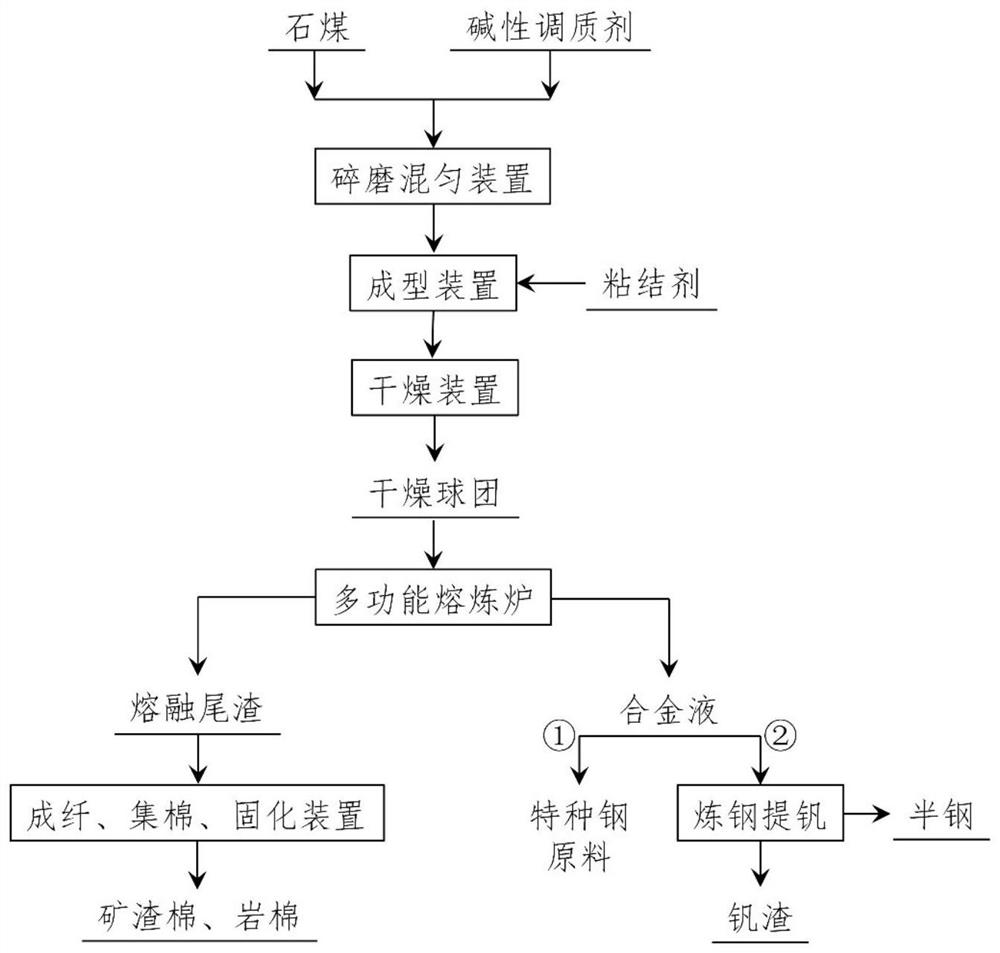

[0047] This embodiment provides a method for processing stone coal, such as figure 1 shown, including the following steps:

[0048] (1) after the stone coal to be treated and the limestone tailings are initially crushed by the crusher respectively, then the two are put into the pulverizer at a ratio of 3:2 for further crushing and uniform mixing;

[0049] Among them, the main components of the stone coal to be treated, the limestone tailings and the mixed materials are shown in Table 1;

[0050] The main components of the stone coal to be treated, the limestone tailings and the mixed material in Table 1 Example 1

[0051] sample V 2 O 5

Fe 2 O 3

C CaO SiO 2

MgO Al 2 O 3

TiO 2

Stone coal to be processed 1.21 6.53 18.44 11.64 50.85 3.89 7.32 0.12 limestone tailings — 15.90 — 50.41 25.23 5.72 2.32 0.42 material after mixing 0.73 10.28 11.06 27.15 40.60 4.62 5.32 0.24

[0052] The acidi...

Embodiment 2

[0059] This embodiment provides a method for processing stone coal, such as figure 1 shown, including the following steps:

[0060] (1) after the stone coal to be treated and the limestone tailings are preliminarily crushed by the crusher respectively, then the two are put into the pulverizer at a ratio of 7:3 for further crushing and uniform mixing;

[0061] Among them, the main components of the stone coal, limestone tailings and mixed materials to be treated are shown in Table 2;

[0062] The main components of the stone coal to be treated, the limestone tailings and the mixed material in the embodiment 2 of table 2

[0063]

[0064]

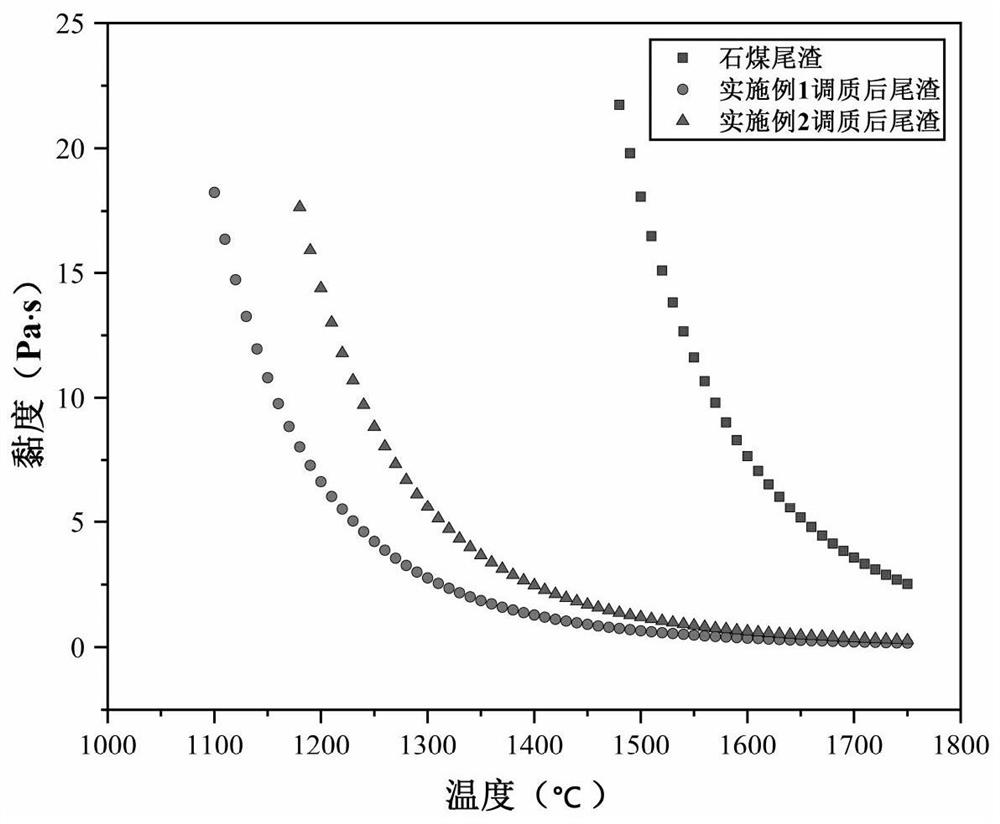

[0065] The acidity coefficient of the material tailings after mixing is 1.8, and the viscosity-temperature curves of the molten tailings before and after quenching and tempering are as follows: figure 2 shown; by figure 2 It can be seen that after quenching and tempering, the suitable fiber-forming temperature range is in the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com