Porous silica gel supported ionic liquid polymer for adsorbing CO2 and preparation method thereof

An ionic liquid, porous silica gel technology, applied in separation methods, educts, chemical instruments and methods, etc., can solve the problems of small specific surface area, unfavorable gas dissolution and diffusion, unfavorable large-scale industrial applications, etc., and achieve good adsorption performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

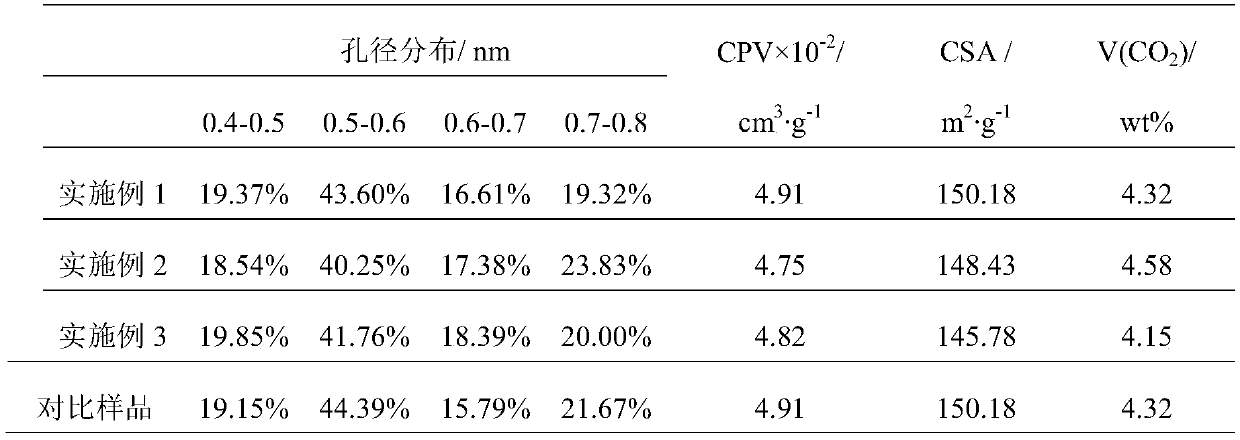

Examples

Embodiment 1

[0032] an adsorbed CO 2 The preparation method of porous silica gel immobilized ionic liquid polymer 1, comprises the following steps:

[0033] 1) Weigh 2-bromoethylamine hydrobromide, N-vinylimidazole, N-vinylimidazole and lithium bistrifluoromethanesulfonylimide in a molar ratio of 1:1:1, and mix 2-bromoethylamine Ethylamine hydrobromide and N-vinylimidazole were placed in a round-bottomed flask and mixed evenly, then absolute ethanol was added, and the time was 20 minutes at a temperature of 25°C. Among them, 2-bromoethylamine hydrobromide and The volume ratio of the total volume of N-vinylimidazole to absolute ethanol is 1:2;

[0034] 2) The temperature of the solution obtained in step 1) was raised to 80° C., and then maintained at a constant temperature for 25 hours, and then titrated and neutralized with a 10% NaOH solution to a pH of 7;

[0035] 3) Use a rotary evaporator to remove the ethanol and water contained in the solution obtained in step 2) neutralization rea...

Embodiment 2

[0044] an adsorbed CO 2 The preparation method of porous silica gel immobilized ionic liquid polymer 2, comprises the following steps:

[0045] 1) Weigh 2-bromoethylamine hydrobromide, N-vinylimidazole, N-vinylimidazole and lithium bistrifluoromethanesulfonylimide in a molar ratio of 1:1.2:1, and mix 2-bromoethylamine Ethylamine hydrobromide and N-vinylimidazole were placed in a round-bottomed flask and mixed evenly, then absolute ethanol was added, and the time was 10 minutes at a temperature of 30°C. Among them, 2-bromoethylamine hydrobromide and The volume ratio of the total volume of N-vinylimidazole to absolute ethanol is 1:3;

[0046] 2) The temperature of the solution obtained in step 1) was raised to 90° C., and then maintained at a constant temperature for 20 h, and then titrated and neutralized with a KOH solution with a mass fraction of 15% until the pH was 7;

[0047] 3) Use a rotary evaporator to remove the ethanol and water contained in the solution obtained in...

Embodiment 3

[0056] an adsorbed CO 2 The preparation method of porous silica gel immobilized ionic liquid polymer 3, comprises the following steps:

[0057] 1) Weigh 2-bromoethylamine hydrobromide, N-vinylimidazole, N-vinylimidazole and lithium bistrifluoromethanesulfonylimide in a molar ratio of 1:1:1.5, and mix 2-bromoethylamine Ethylamine hydrobromide and N-vinylimidazole were placed in a round-bottomed flask and mixed evenly, then absolute ethanol was added, and the time was 30 minutes at a temperature of 20°C. Among them, 2-bromoethylamine hydrobromide and The volume ratio of the total volume of N-vinylimidazole to absolute ethanol is 1:1;

[0058] 2) The temperature of the solution obtained in step 1) is raised to 70° C., and then kept at a constant temperature for 30 hours, and then the mass fraction is 8% Ca(OH) 2 The solution is titrated and neutralized to a pH of 7;

[0059] 3) Use a rotary evaporator to remove the ethanol and water contained in the solution obtained in step 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com