Film separation method for difluo-monochloromethane and trifluoromethane mixture

A technology of difluoromonochloromethane and trifluoromethane, which is applied in the production of chlorodifluoromethane, the disproportionation separation/purification of halogenated hydrocarbons, organic chemistry, etc. Waste of F22 products and other problems, to achieve the effect of safe and reliable use, small one-time investment, and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

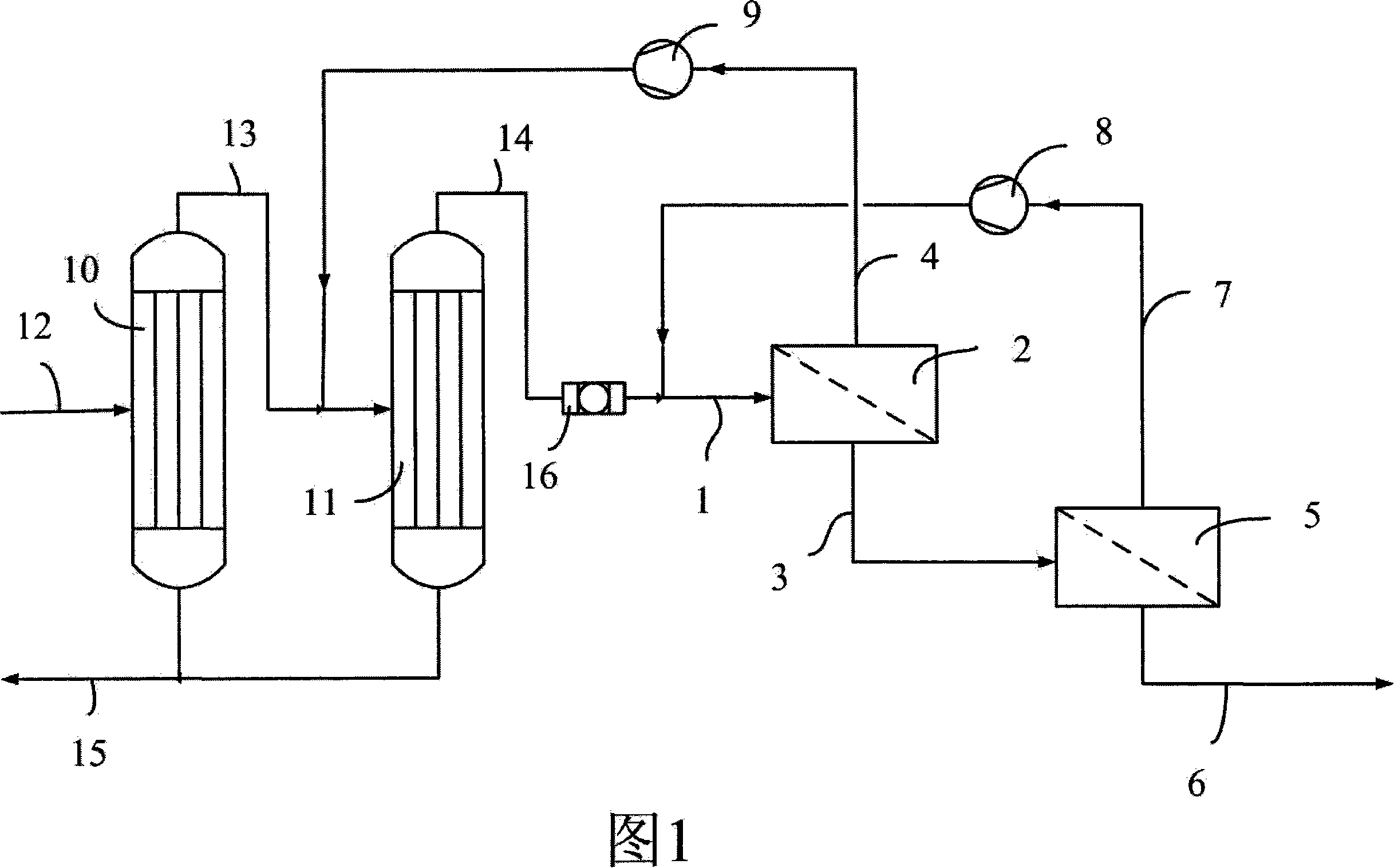

[0029] As shown in Figure 1, the mixed gas of difluorochloromethane and trifluoromethane produced in industrial production first enters the condensation tower 10 through the production inlet pipeline 12, and then enters the condensation tower 11 through the condensation tower tail gas pipeline 13, and the liquefied two Chlorofluoromethane is discharged from the bottom of the condensation tower through the condensation recovery pipeline 15. The mixed gas of difluorochloromethane and trifluoromethane that has passed through the condensation tower 10 and the condensation tower 11 and has not been condensed is drawn out through the tail gas pipeline 14 of the condensation tower, and the solid impurities and liquid droplets are removed by the precision filter 16, and then passed through the tail gas inlet pipeline 1 It enters the gas membrane separation module 2 in gaseous state, the permeate gas is collected through the permeate gas pipeline 4 and then sent back to the condensation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com