Preparation method of ethylene-tetrafluoroethylene copolymer with high thermal stability

A technology with high thermal stability and tetrafluoroethylene, which is applied in the field of preparation of fluoropolymers, can solve the problems of limiting polymer performance and application fields, not improving the thermal stability of ETFE, and limiting the application of ETFE, reaching the product application range Wide range, good product performance, and large operating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

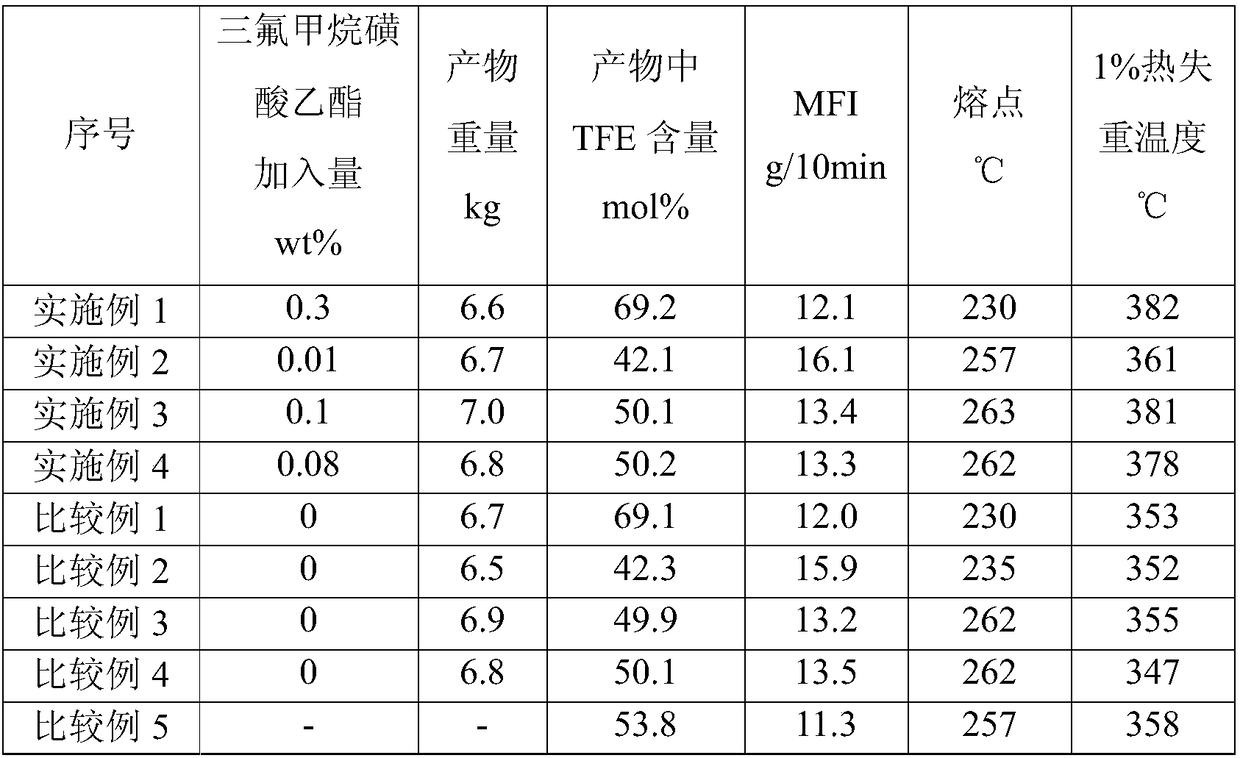

Examples

Embodiment 1

[0025] Add 60 kg of solvent C to a 100L stainless steel high-pressure vertical reactor 2 Cl 3 f 3 , and add 600 grams of liquid phase monomer perfluorohexylethylene, chain transfer agent methanol 50 grams, then add ethyl trifluoromethanesulfonate, its addition is C 2 Cl 3 f 3 0.3% by weight, start stirring and keep the temperature of the kettle at 80°C, and add the mixed gas of tetrafluoroethylene and ethylene (the molar ratio of tetrafluoroethylene to ethylene = 90:10) into the reaction kettle through a membrane press until the pressure is 20bar. Add 20 grams of diisopropyl peroxydicarbonate to initiate polymerization, and continue to add the mixed gas of tetrafluoroethylene and ethylene (tetrafluoroethylene and ethylene molar ratio=70:30) by membrane press simultaneously so that the reactor pressure is maintained at 20bar, and maintain the temperature of the kettle at 80°C. When the mixed gas of tetrafluoroethylene and ethylene reaches 4.8 kg, the polymerization reaction...

Embodiment 2

[0028] Add 78 kg of solvent C to the 100L stainless steel high-pressure vertical reactor 7 f 14 , and add 800 grams of liquid phase monomer perfluoropropyl vinyl ether, 150 grams of chain transfer agent cyclohexane, then add ethyl trifluoromethanesulfonate, and its addition is C 7 f 14 0.01% by weight, start stirring and keep the temperature of the kettle at 40°C, add the mixed gas of tetrafluoroethylene and ethylene (the molar ratio of tetrafluoroethylene to ethylene = 60:40) into the reaction kettle through a membrane press until the pressure is 10bar, Add 100 grams of tert-butyl peroxypivalate to initiate polymerization, and continue to add the mixed gas of tetrafluoroethylene and ethylene (tetrafluoroethylene and ethylene molar ratio=40:60) by membrane press simultaneously so that the reactor pressure is maintained at 10bar, and maintain the temperature of the kettle at 40°C. When the mixed gas of tetrafluoroethylene and ethylene reaches 3.3 kg, the polymerization reacti...

Embodiment 3

[0031] Add 51 kg of solvent CCl to a 100L stainless steel high-pressure vertical reactor 2 f 2 , and add 400 grams of liquid phase monomer perfluorobutyl ethylene, 150 grams of chain transfer agent acetone, then add ethyl trifluoromethanesulfonate, and its addition is CCl 2 f 2 0.1% by weight, start stirring and keep the temperature of the kettle at 60°C, add the mixed gas of tetrafluoroethylene and ethylene (the molar ratio of tetrafluoroethylene to ethylene = 75:25) into the reaction kettle through a membrane press until the pressure is 15bar, add 80 grams of tert-butyl peroxyisobutyrate start to initiate polymerization, while the mixed gas of tetrafluoroethylene and ethylene (tetrafluoroethylene and ethylene molar ratio=50:50) is continuously added by a membrane press so that the reactor pressure is maintained at 15bar , and maintain the temperature of the kettle at 60°C. When the mixed gas of tetrafluoroethylene and ethylene reaches 7.8 kg, the polymerization reaction is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com